Studying Critical elements in PCB systems: Plated Through Via (PTV)

- Posted by Mari Carmen López

- On March 13, 2020

- 0

Plated Through Vias (PTV) are critical elements in PCB systems and special care must be paid during their inspection in order to ensure the reliability, as they are one the main factors that determine the PCB Quality.

The functionality and reliability of PTVs are dictated by: the plated through hole architecture (height / diameter), plating (thickness and quality) and other PCB general characteristics (materials and design).

Main PTV failures mechanism can be grouped in the following categories:

Quality standards like IPC-A-600, ECSS-Q-ST-70-60C Dir.1 or MIL–PRF–31032/1C state the requirements for a functional Plated Through Vias in order to ensure the general quality of the board. The present post reviews the main imperfections of PTV and the relationship with the manufacturing process.

The actual Plated Through Vias status is usually not noticeable by conventional visual inspection even with the aid of high magnification system and microsection analysis become mandatory for the suitable inspection of PCB systems. Furthermore, cross-sectional views are not only used to assess quality but they also may provide critical information about the likely failure mechanism and causes which makes the technique a very valuable tool in failures analyses.

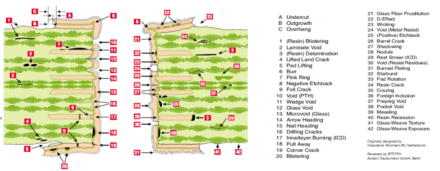

Comprehensive micro sectioning inspection of PTVs may reveal a rich variety of defects and deviations such as those illustrated in Figure 1. Amongst them, this post focuses the attention on those more commonly observed and identified as rejection cause in international quality standards (e.g. ECSS-Q-ST-70-60C Dir.1).

Figure 1 From ECSS-Q-ST-70-60C Dir.1

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Why Microsectioning sample preparation of PCB systems? - May 19, 2021

- Inspection of conformal coating on PCB using UV Light - August 4, 2020

- Plating Thickness Testing Overview in Alter Technology Lab. - July 28, 2020

0 comments on Studying Critical elements in PCB systems: Plated Through Via (PTV)