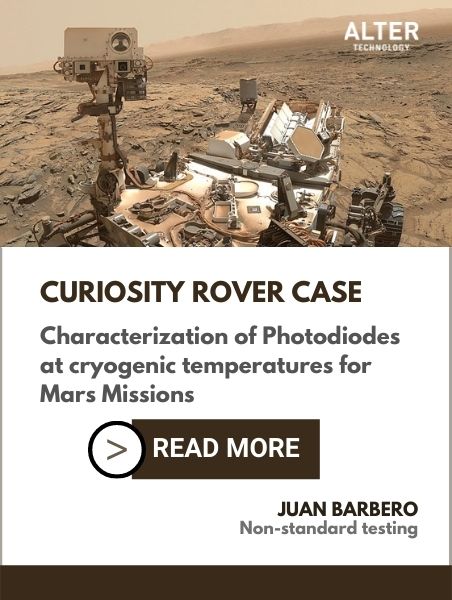

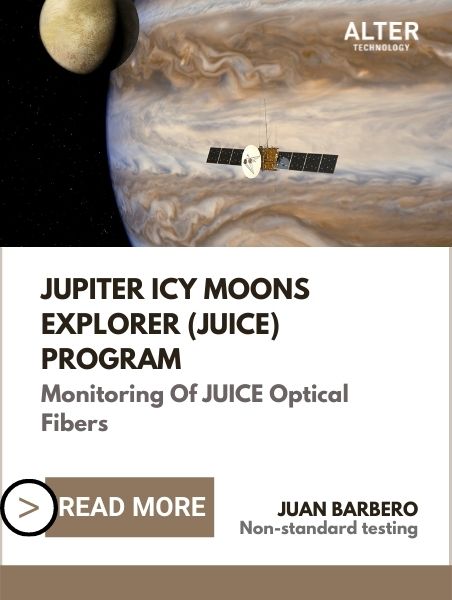

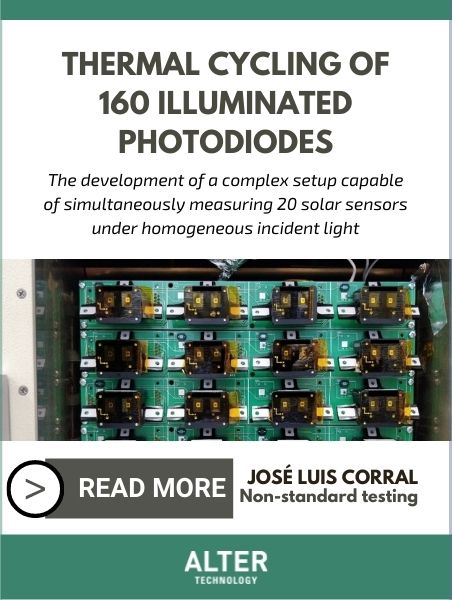

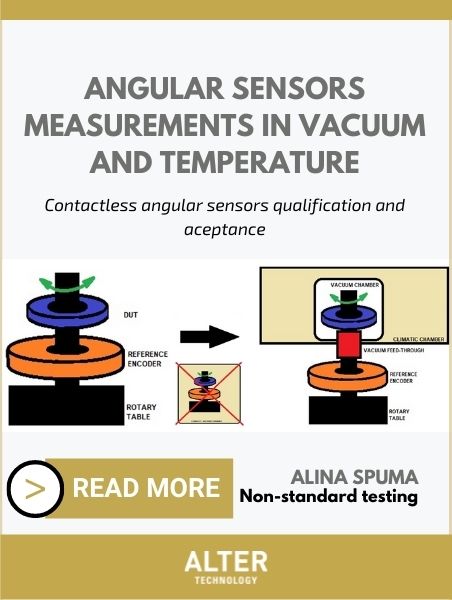

We develop special setups to do non-standard testing: Thermal Vacuum, Ambient Cycling, and Custom developments for testing (power lasers, temp sensors). Tests that no one else would be able to do.

ALTER is putting an important effort into developing new capabilities to validate new technologies (i.e., optoelectronics and MEMS) for space applications and extending these testing capabilities from the part level to instrument or system level.

In addition, the experience of ALTER in the management of space projects, together with the commitment of the company to the research and development activities, has been reflected in the participation of the company in a large number of projects as coordinator of other research and/or development groups.