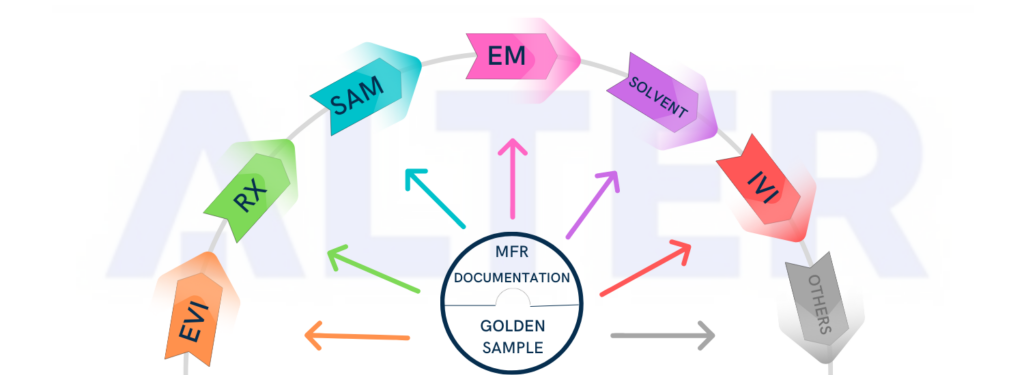

ALTER Authenticity Test Lab provides a complete process of the technical management of the supply chain, from supplier selection and monitoring to inspections and testing techniques aimed at preventing and detecting counterfeit electronic parts entering the manufacturing line.

Authenticity Testing is performed by various inspections and testing techniques to prevent counterfeit electronic components. The activity of counterfeiting is not a static process. Indeed, as new methods are defined to detect counterfeit parts, new methods are introduced by counterfeiters to disguise their parts.

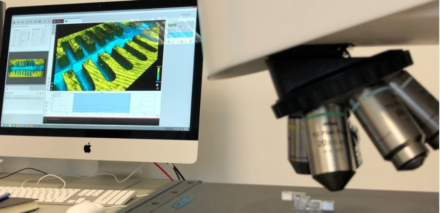

ALTER’s Authenticity Test Lab is in progress of ISO/IEC 17025 accreditation and provides full in-house component testing capabilities.