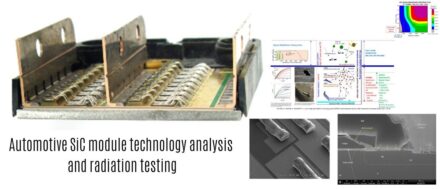

We have Silicon Carbide Diodes customized to the extreme, plus SiC testing capabilities not offered by competitors.

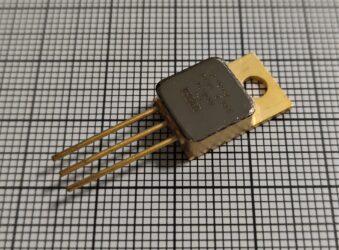

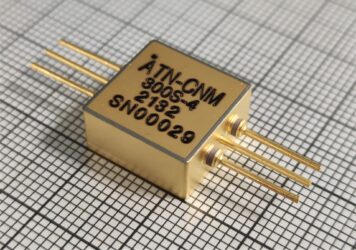

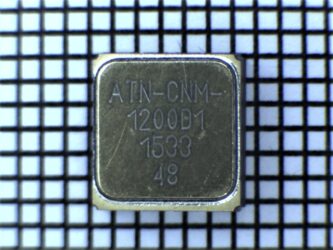

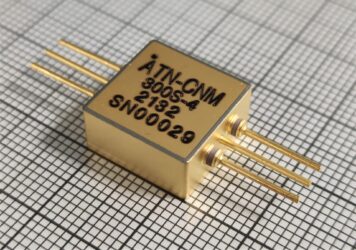

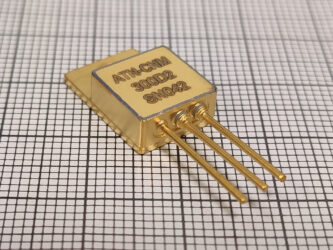

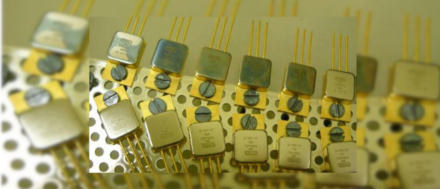

Custom application targeted SiC Schottky diodes (both pure Schottky and JBS). Customizable in die, package, mounting solution, high-temperature operation/high voltage, and fast switching.

Our solution is the only SiC device existing in the EPPL (ESA European Preferred Part List). The European Preferred Part List (EPPL) is an extensive list of parts that can be used as a guideline for projects at the European Space Agency (ESA).

Why SiC?

- SiC will operate up to any temperature you need.

- SiC will allow you to switch faster with 0 recovery time.

- Custom packages can be designed to fit your already existing footprint.

- Custom die configuration will match your application needs, and multichip will enable more compact solutions.