Using a Fluorescence Microscopy + dye penetrant test on EEE Parts

- Posted by Francisco Javier Aparicio Rebollo

- On February 19, 2021

- 0

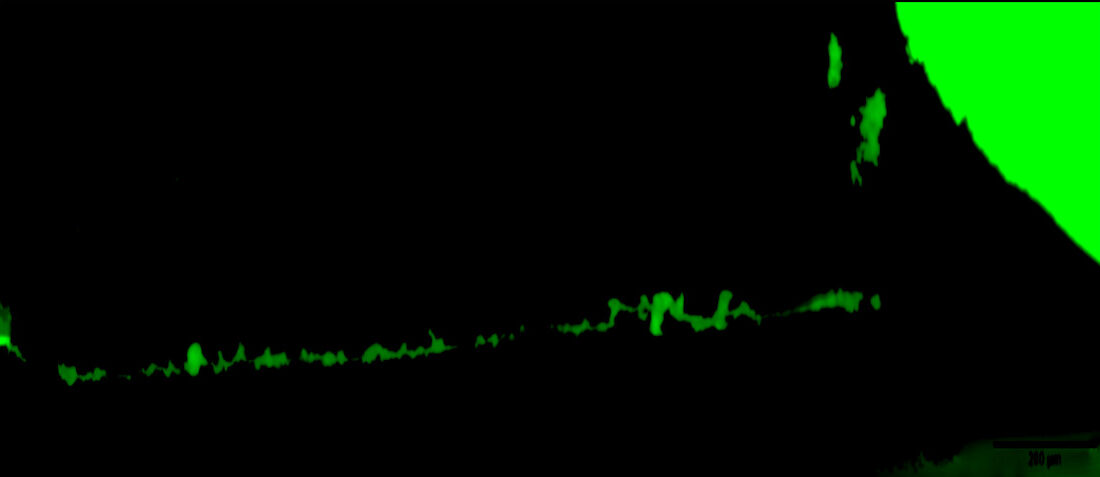

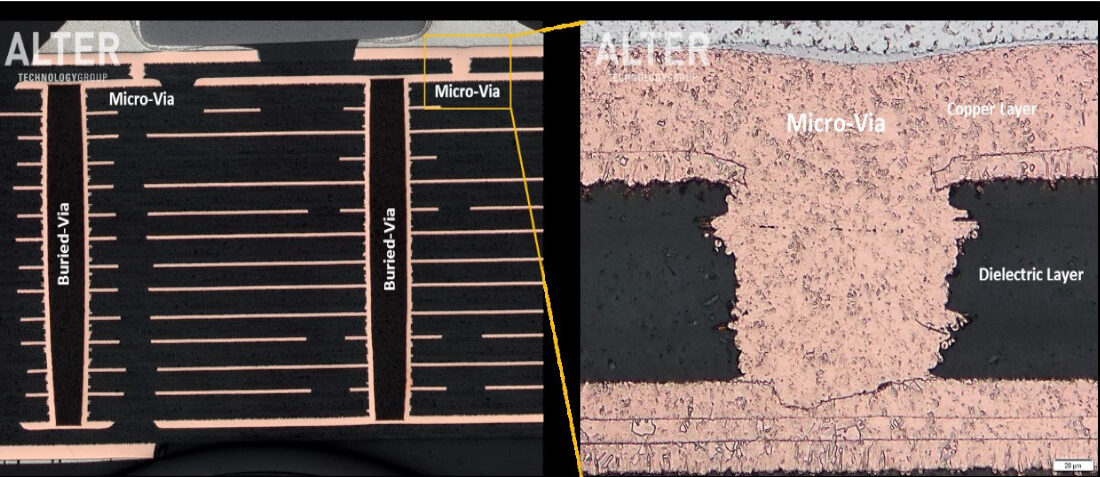

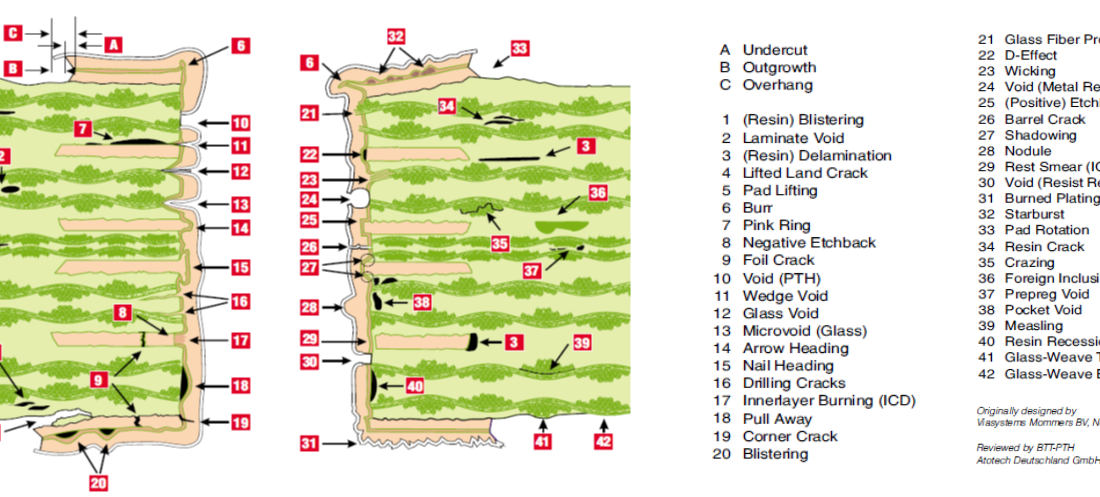

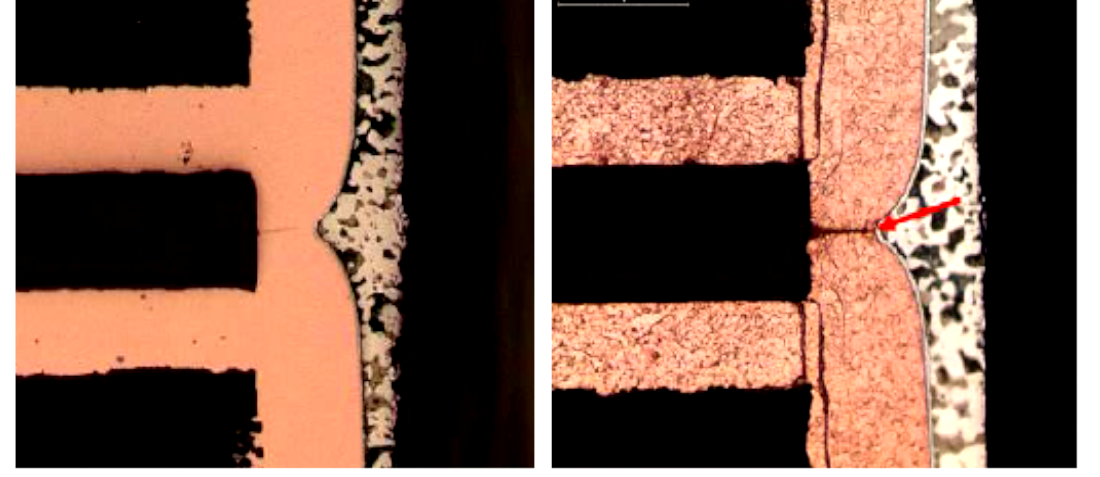

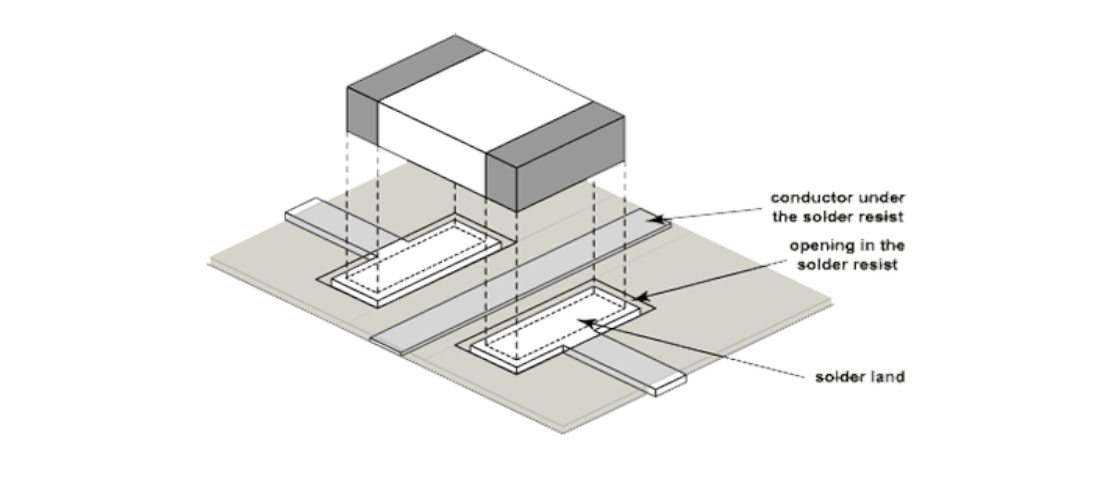

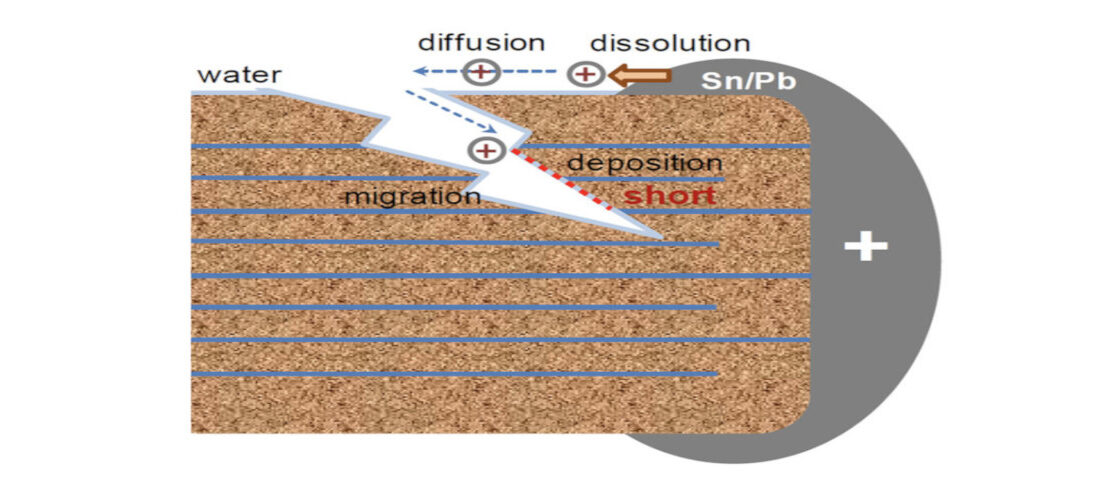

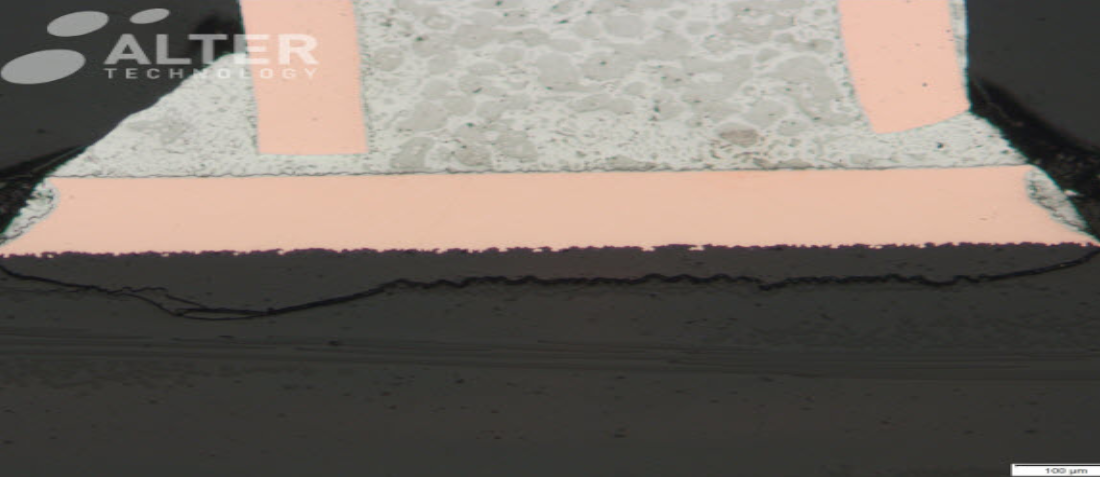

The Fluorescence Microscopy + dye penetrant test is a technique that combines two inspection methods commonly used for the detection of surface anomalies such as cracks, porosity, laps, delaminations, and other discontinuities.