Material analysis identifies elements in microelectronic parts to ensure compliance, reliability, and detection of prohibited materials.

Blog » capacitor basics »

Material analysis identifies elements in microelectronic parts to ensure compliance, reliability, and detection of prohibited materials.

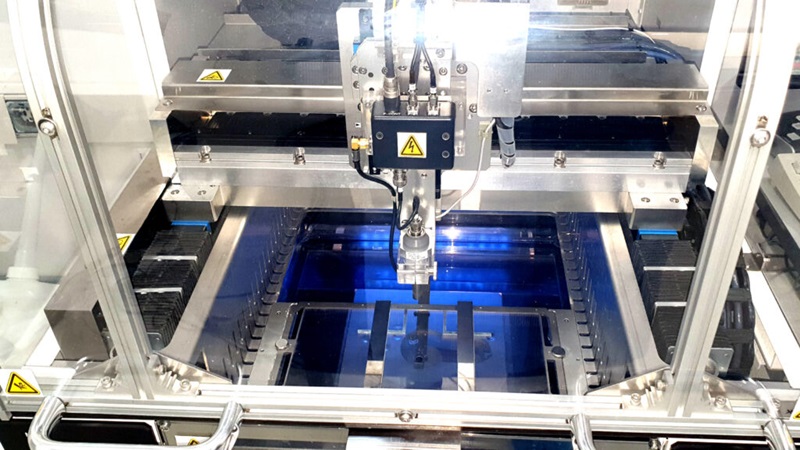

Ultrasonic examination detects submicron internal defects in ceramic capacitors, ensuring reliability through non-destructive analysis.

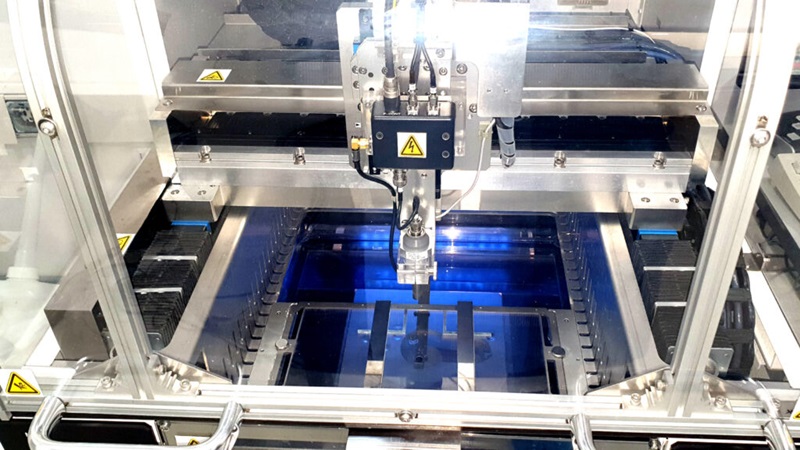

COTS parts undergo safe C-SAM inspection using deionized water, limited immersion, and drying to prevent corrosion and damage.

Decapsulation exposes internal device structures for analysis of die, interconnects, and defects during failure investigations.

Hermeticity testing detects seal integrity in components to prevent contamination and ensure long-term device reliability.

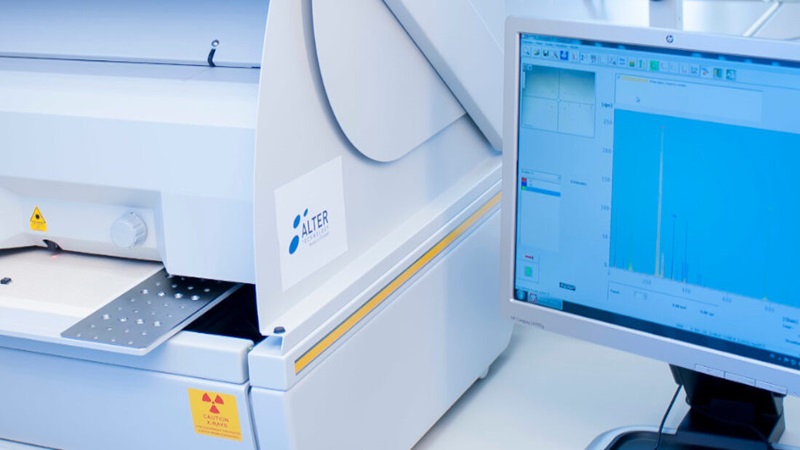

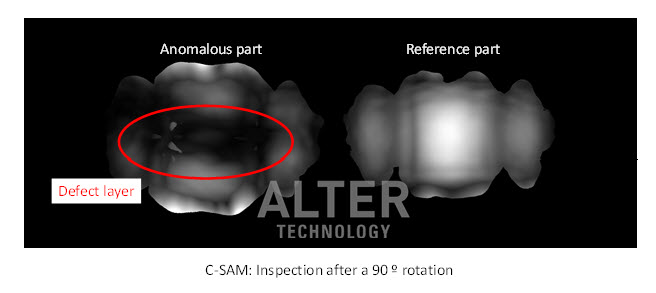

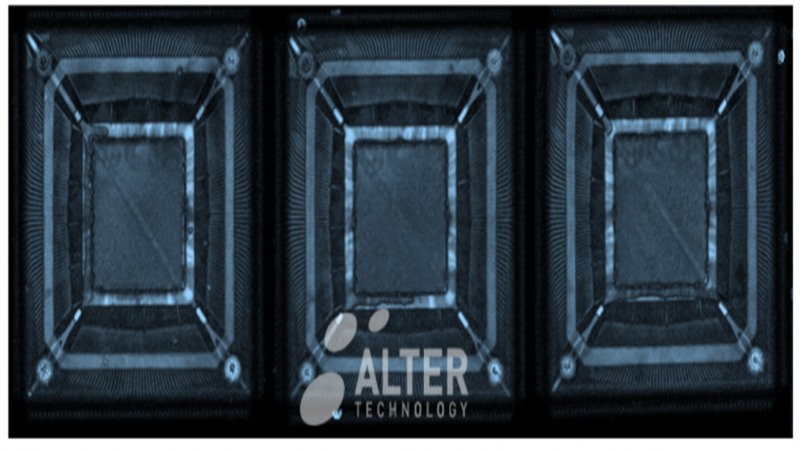

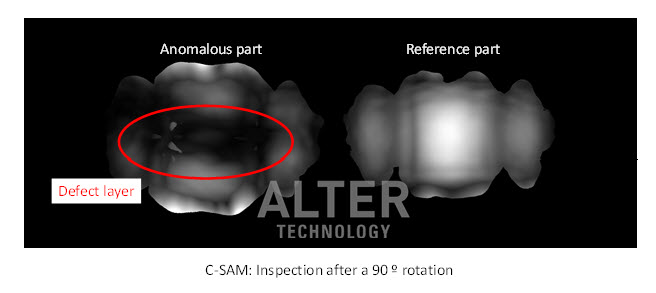

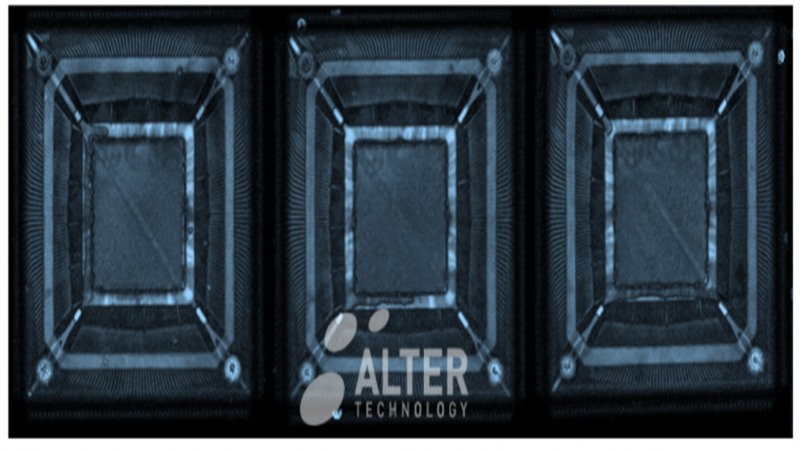

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

C-SAM enables non-destructive inspection of microelectronic parts, detecting internal defects across critical applications.

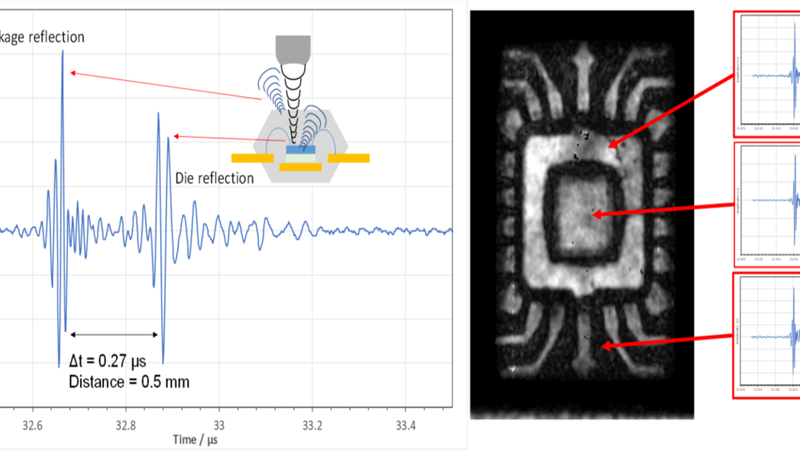

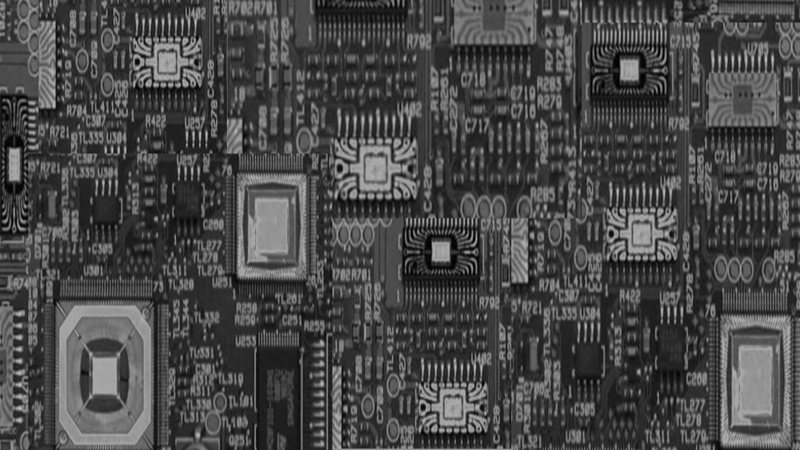

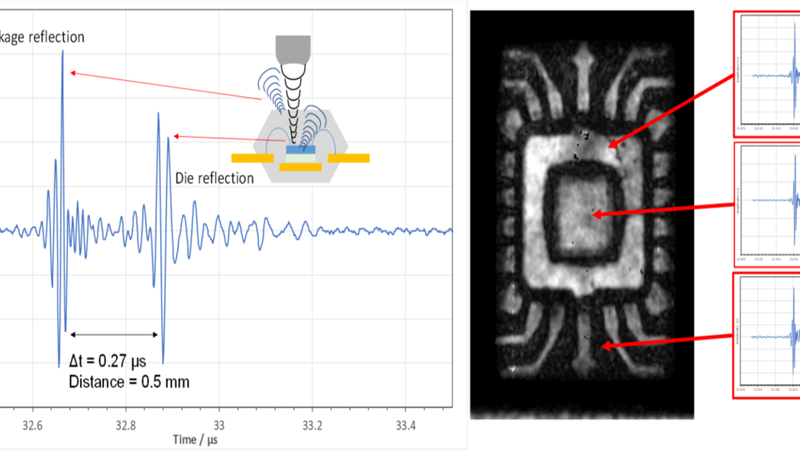

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

SAM enables non-destructive internal inspection of microelectronic parts by analyzing acoustic wave reflections and contrasts.

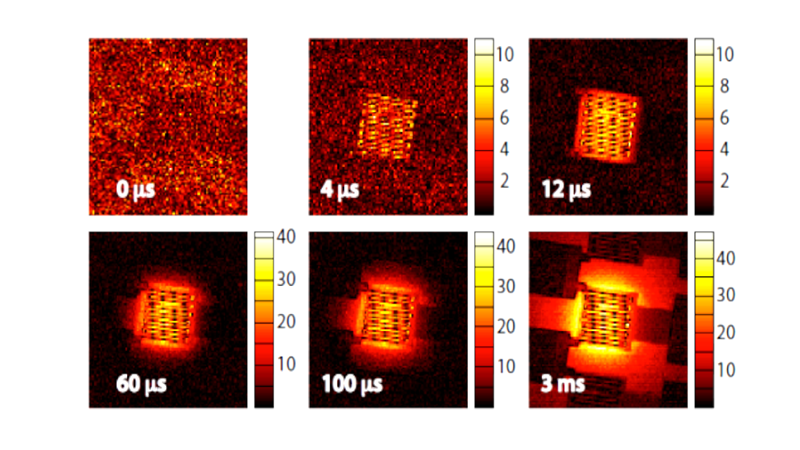

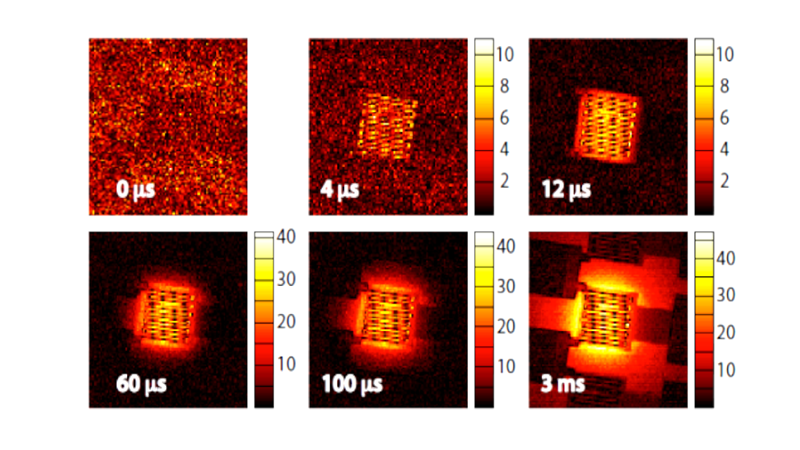

Thermoreflectance Thermal Imaging (TTI) maps micro-scale temperature gradients in devices with high spatial and temporal resolution.

Material analysis identifies elements in microelectronic parts to ensure compliance, reliability, and detection of prohibited materials.

Ultrasonic examination detects submicron internal defects in ceramic capacitors, ensuring reliability through non-destructive analysis.

COTS parts undergo safe C-SAM inspection using deionized water, limited immersion, and drying to prevent corrosion and damage.

Decapsulation exposes internal device structures for analysis of die, interconnects, and defects during failure investigations.

Hermeticity testing detects seal integrity in components to prevent contamination and ensure long-term device reliability.

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

C-SAM enables non-destructive inspection of microelectronic parts, detecting internal defects across critical applications.

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

SAM enables non-destructive internal inspection of microelectronic parts by analyzing acoustic wave reflections and contrasts.

Thermoreflectance Thermal Imaging (TTI) maps micro-scale temperature gradients in devices with high spatial and temporal resolution.