Failure Mechanism of Metallized Film Capacitors under DC Field Superimposed AC Harmonic

- Posted by doEEEt Media Group

- On September 5, 2024

- 0

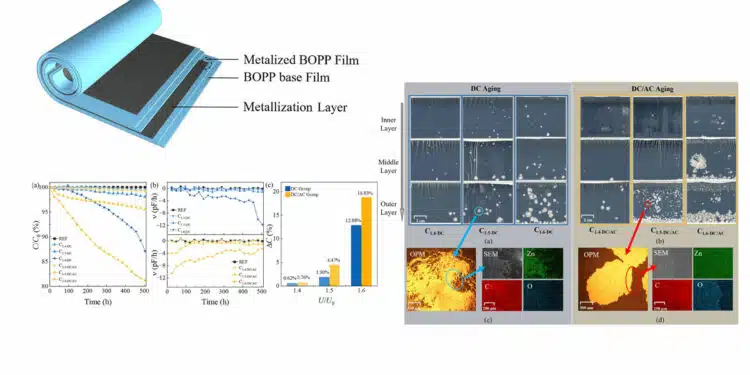

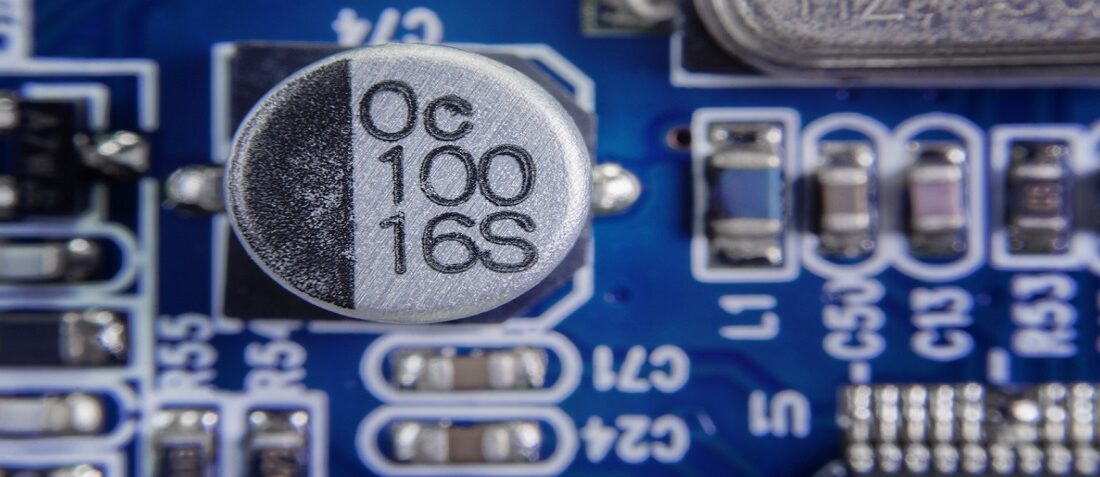

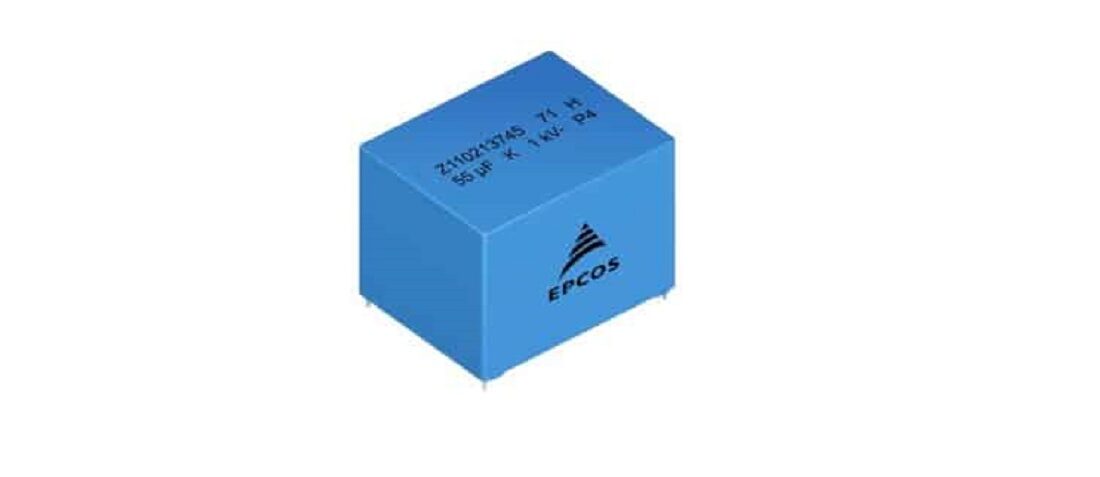

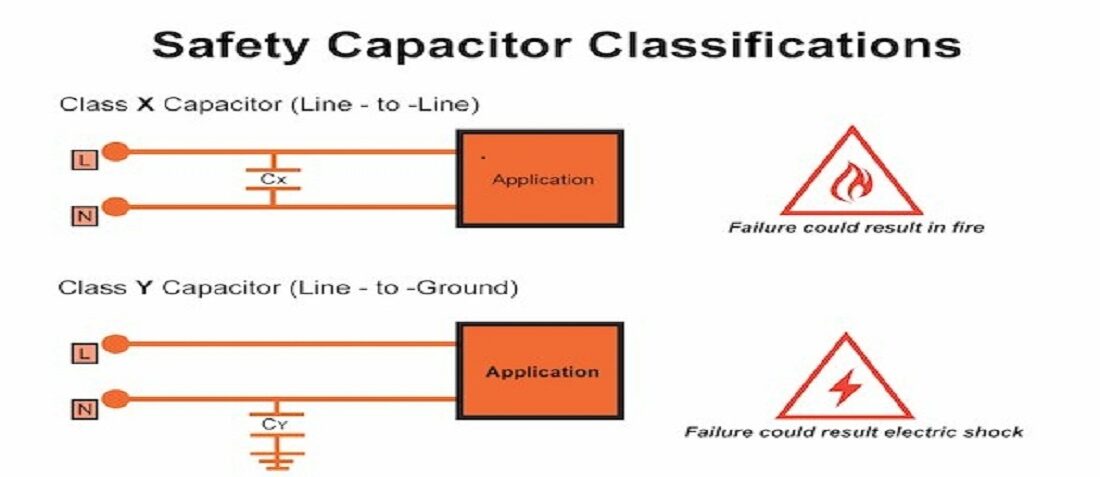

Researchers investigated the failure mechanisms of metallized film capacitors (MFCs) under DC/AC-superimposed conditions in HVDC systems. They found that capacitors aged under DC/AC fields experienced shorter lifespans, faster capacitance decay, and greater material degradation than those aged solely under DC fields due to electrode loss and molecular structure damage.