MIL-STD-883 METHOD 2003 – Solderability Testing

- Posted by Manuel Padial Pérez

- On July 23, 2020

- 0

Mil-Std-883 Method 2003- Solderability Testing employs the Dip and Look Method, requiring the following equipment:

- A solder pot to maintain solder at a specified temperature.

- A steam aging equipment for ‘aging’ the samples prior to testing

- A dipping mechanism capable of controlling the rates of immersion and emersion and dwell time of the terminations.

- A microscopy system to facilitate the external visual inspection at a minimum magnification of 10X.

The general solderability test procedure consists of the following steps following the Mil-Std-883 Method 2003:

- Proper preparation of the samples which must not include wiping, cleaning, scraping, or abrasive cleaning of the terminations to be tested.

- Aging of the samples in a steam ager, consisting on exposing the surfaces to be tested to water vapour for 8 hours and drying them, either by baking at 100ºC for no more than 1 hour in a dry atmosphere or air drying the mat ambient temperature for a minimum of 15 minutes.

- Proper application of flux to the terminations.

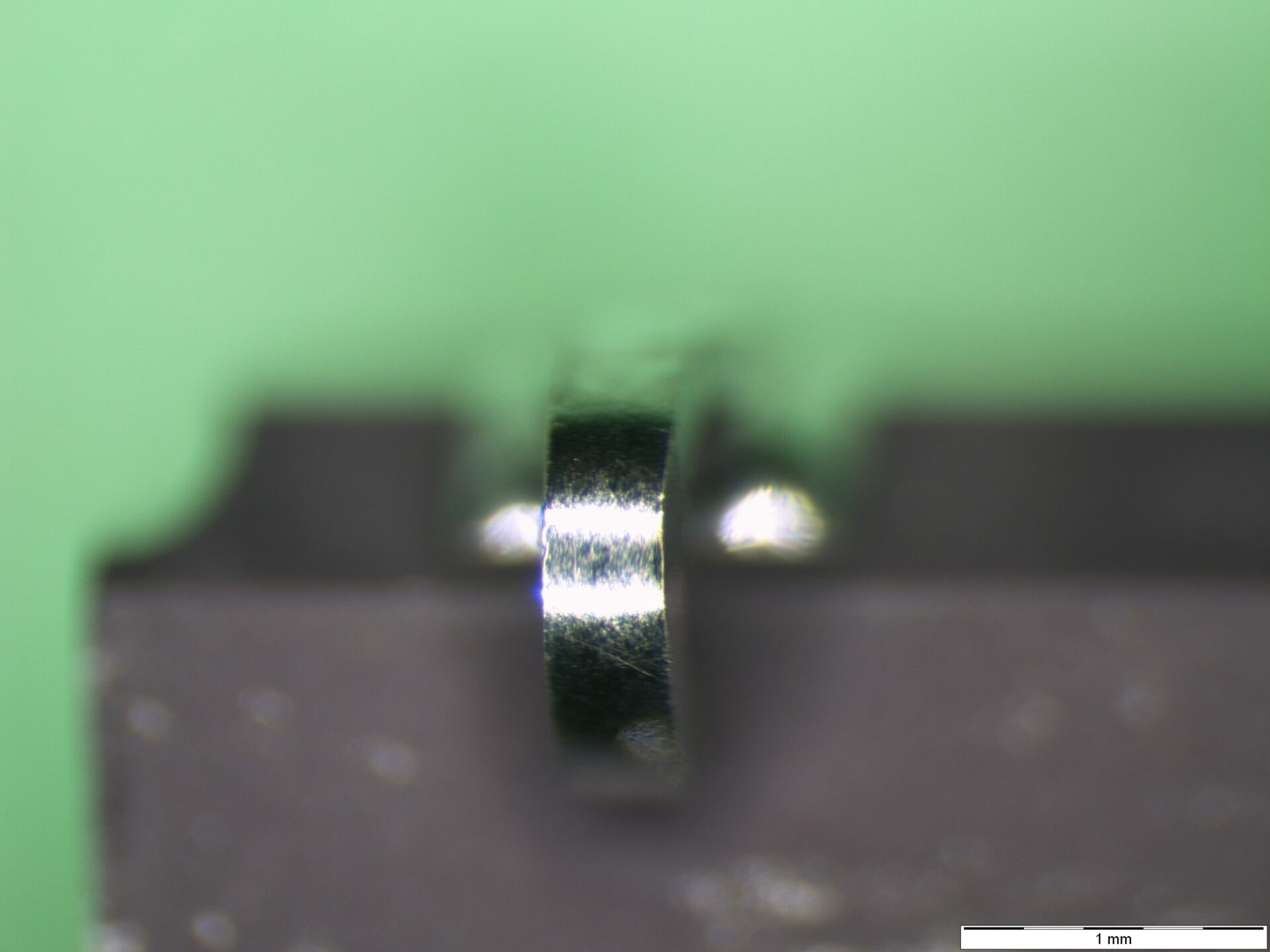

- Solder dipping by immersing the terminations in static solder at a uniform temperature of 245ºC +/- 5º C.

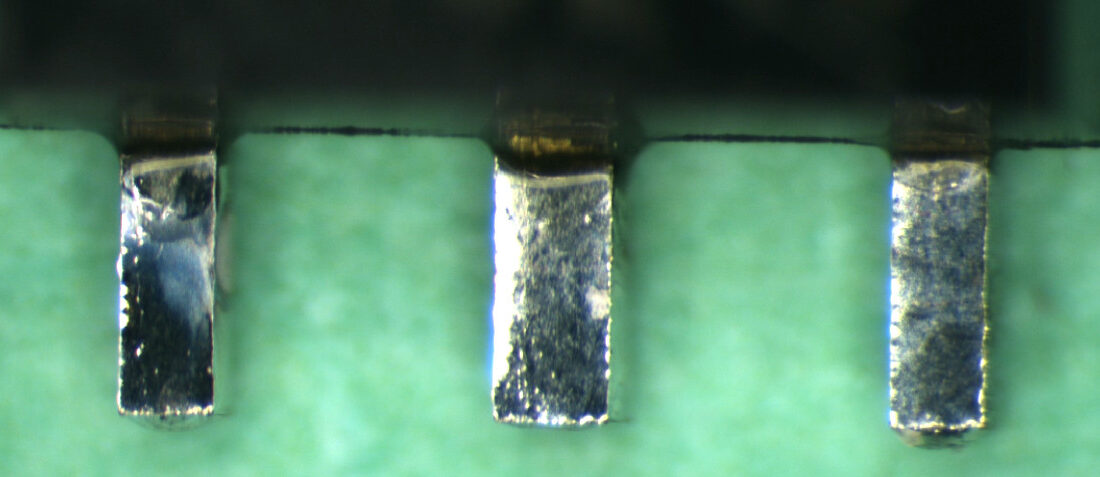

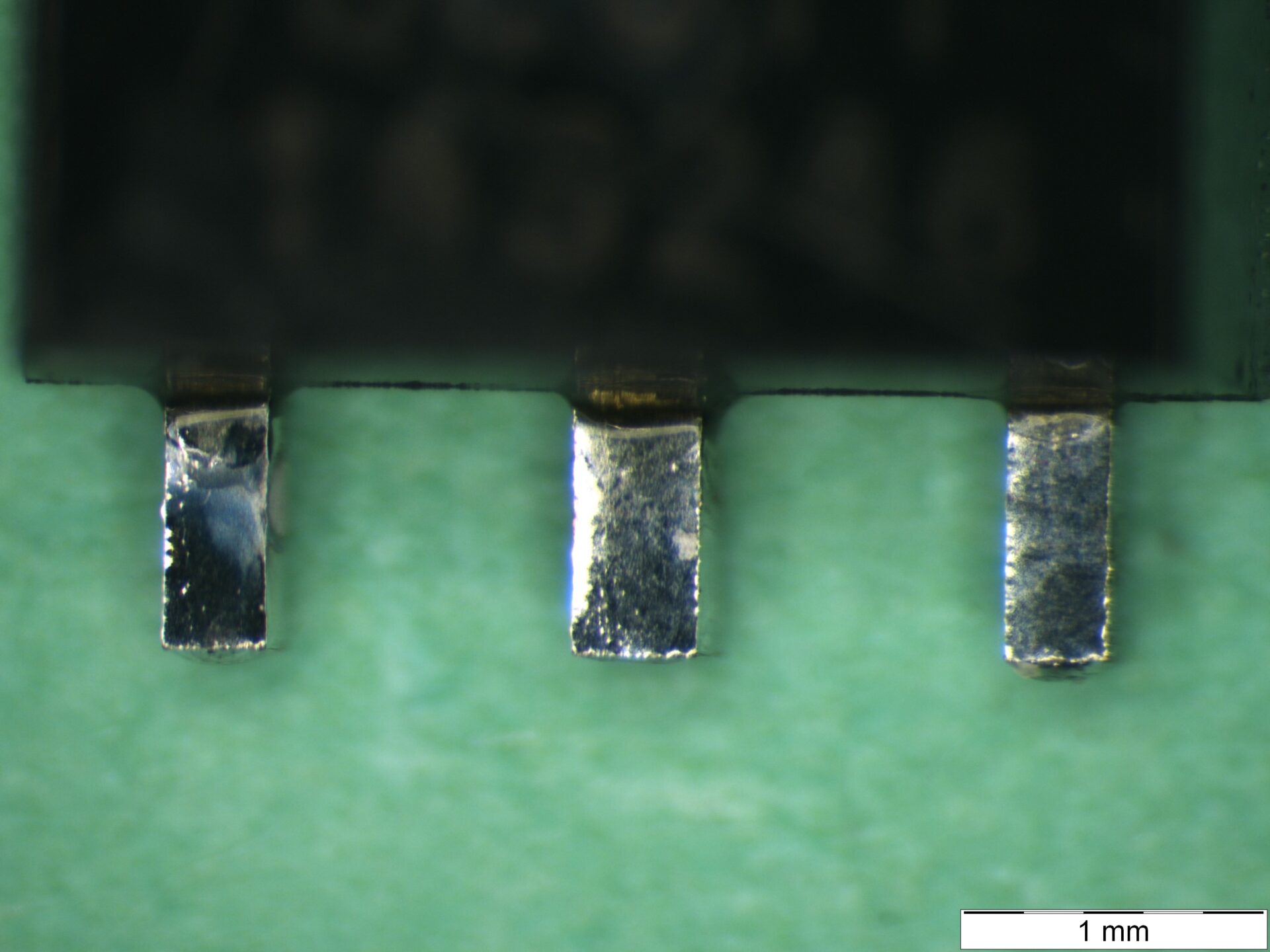

- Examination of the terminations at 10-15X magnification.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

Solderability Testing

The main criterion for acceptable solderability is 95% coverage of the dipped portion of the terminations by a new and continuous solder coating. Thus, pinholes, voids, porosity, nonwetting, or dewetting must not exceed 5% of the total dipped area.

Documents and specifications related to your component can be found in doEEEt

Latest posts by Manuel Padial Pérez (see all)

- Hi-Rel Intermediate bus converter and point of load - December 11, 2021

- ASIC or FPGA, how to choose between them - October 25, 2021

- Ceramic Hermetic DDR2 SDRAM Memory avalaible for Space - September 13, 2021

0 comments on MIL-STD-883 METHOD 2003 – Solderability Testing