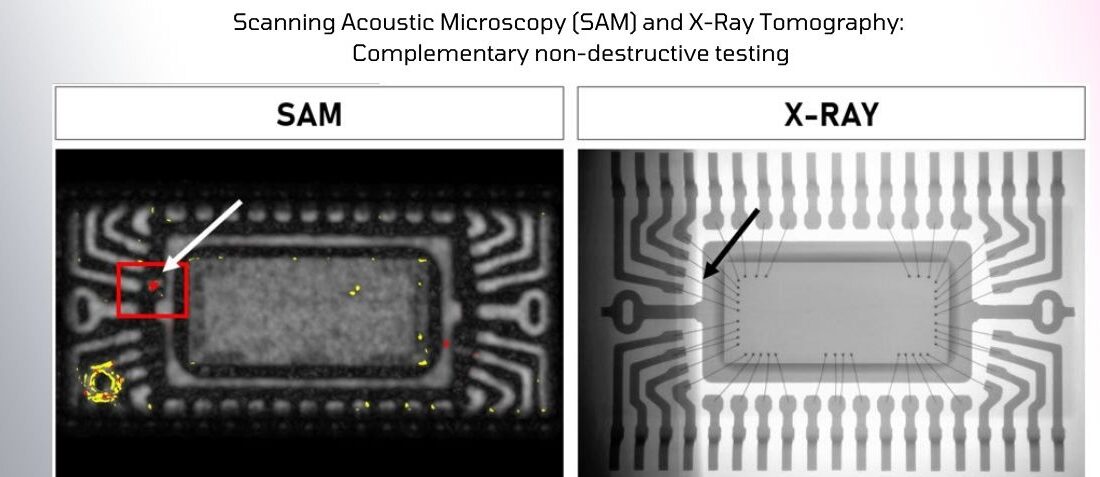

Scanning Acoustic Microscopy (SAM) and X-Ray Tomography

- Posted by doEEEt Media Group

- On April 26, 2022

- 0

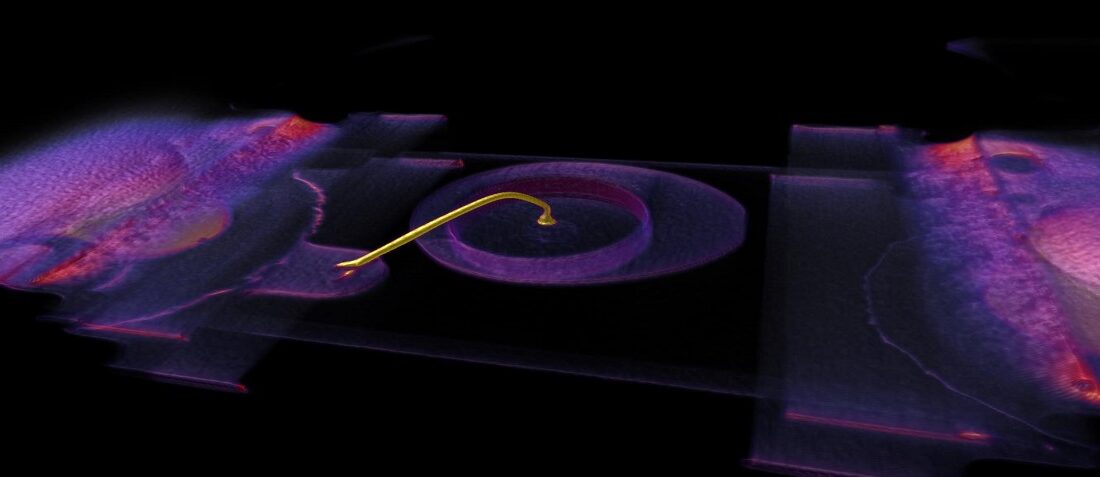

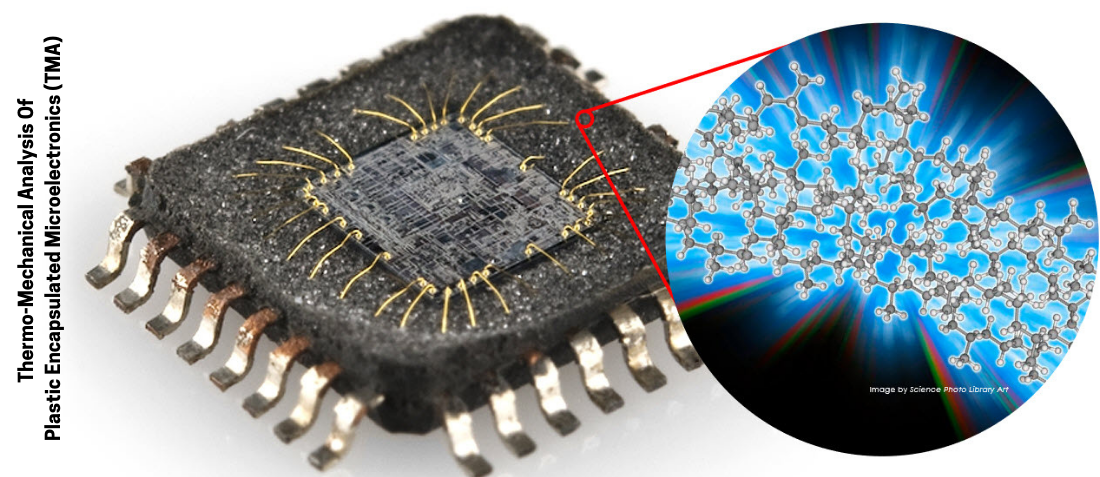

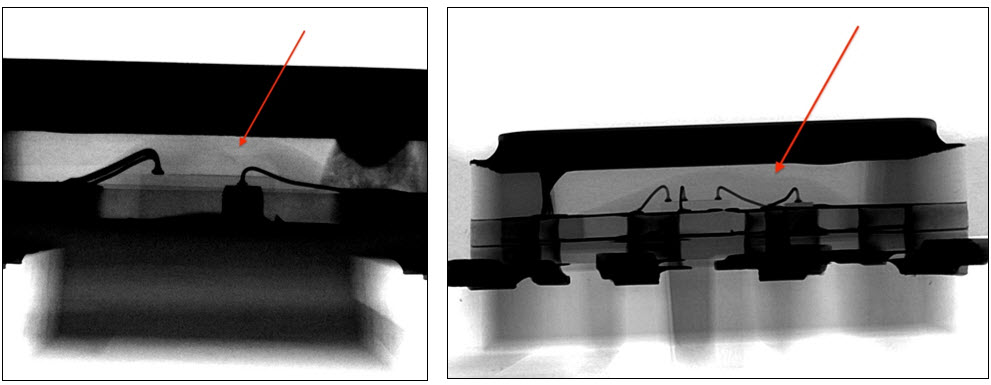

The Scanning Acoustic Microscopy (SAM) technique is the most effective and complete non-destructive approach for the detection of critical and latent anomalies within plastic encapsulated parts, either on assembled or non-assembled systems