Scanning Acoustic Microscopy (SAM) and X-Ray Tomography

- Posted by doEEEt Media Group

- On April 26, 2022

- 0

Complementary non-destructive testing

The Scanning Acoustic Microscopy (SAM) technique is the most effective and complete non-destructive approach for the detection of critical and latent anomalies within plastic encapsulated parts, either on assembled or non-assembled systems: Therefore, it is routinely used and required to screen out potentially defective parts before the implementation into different industrial sectors such as automotive, military industry, avionics, space applications, and others.

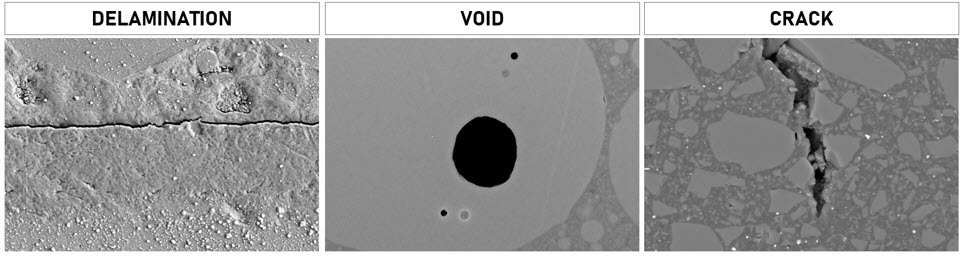

Such a technique is sensitive to density changes, making it reliable and accurate in detecting “air-gap anomalies” such as delaminations, voids, and cracks.

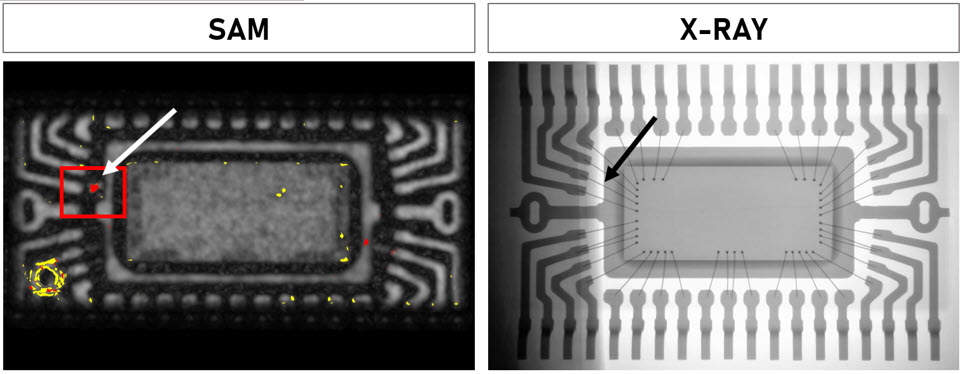

The difficulty of this technique when carrying out the inspection is due to its non-destructive nature. This makes it impossible to know the device’s internal structure in advance. For that reason, preliminary X-ray inspection is systematically conducted to identify the critical focal planes for multifocal SAM inspections. However, the X-Ray inspection does not detect the “air-gap anomalies” spotted by SAM. For that reason, SAM and X-Ray are complementary techniques.

The picture above shows a case where a void was detected during SAM inspection. This anomaly is in the same plane as a wire connecting the lead frame to the die, potentially endangering the mechanical stability of the structure and affecting the functionality of the device. As you can see in the X-Ray image, there is no evidence of delamination since this technique is not sensitive to this kind of defect. However, the X-Ray image provides essential information (in this case, the presence of the wires) that is key to differentiating between a pass or reject the result.

Related Post

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Converging Commercial-Off-The-Shelf (COTS) and Space-Grade - April 8, 2024

- Wirewound Resistors - April 2, 2024

- Resistors Pulse Load, Power and Voltage Derating - April 2, 2024

0 comments on Scanning Acoustic Microscopy (SAM) and X-Ray Tomography