Evaluation of PCB in Alter Technology Lab.

- Posted by Mari Carmen López

- On July 25, 2020

- 0

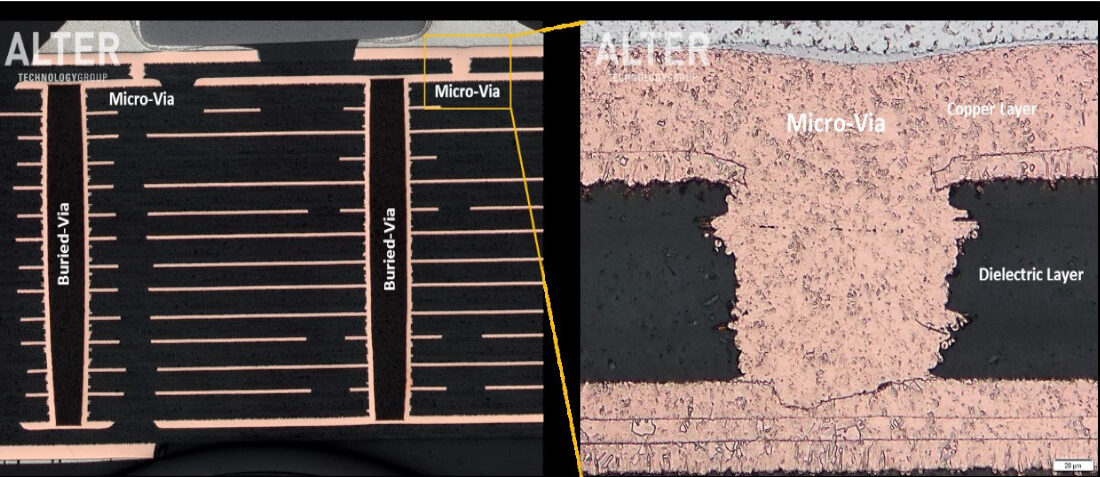

Cross-sectioned PCB are metallographic prepared in ALTER TECHNOLOGY Materials & Processes Laboratory.

Sample & Method

The separation of the interest area has to be performed in such a way as to prevent any damage by deformation or input of heat. After cleaning, the specimen is encapsulated before the grinding process takes place.

Then, rough SiC paper (500 grit) is used to rapidly achieve a surface, 1-0.5 mm away from the plane of interest. The target (the middle of the inspected vias) can be reached by using several short steps during the following processes. Considering that the time selected for each step must ensure that all deformation from the previous process is removed and the target is not reached with a rough SiC paper. Finally, the sample is polished to provide with a smooth and shiny surface to be analyzed.

Metallographic analysis allows us to assess the reliability of the PCB.

Remark

Printed Circuit Board (PCB) are metallographically inspected to ensure the quality of its multilayered structure. This test provides valuable information such as plated through-hole or via dimensions, dielectric lamination conditions, connections between the layers or inner layer copper thickness.

Specifications prepared by ECSS (ECSS-Q-ST-70-60C), NASA and IPC (IPC-6012) define acceptance and rejection criteria for PCB analysis.

Contact us

- Why Microsectioning sample preparation of PCB systems? - May 19, 2021

- Inspection of conformal coating on PCB using UV Light - August 4, 2020

- Plating Thickness Testing Overview in Alter Technology Lab. - July 28, 2020

0 comments on Evaluation of PCB in Alter Technology Lab.