Component Testing for New Space Applications

- Posted by Enrique Cordero

- On July 2, 2021

- 0

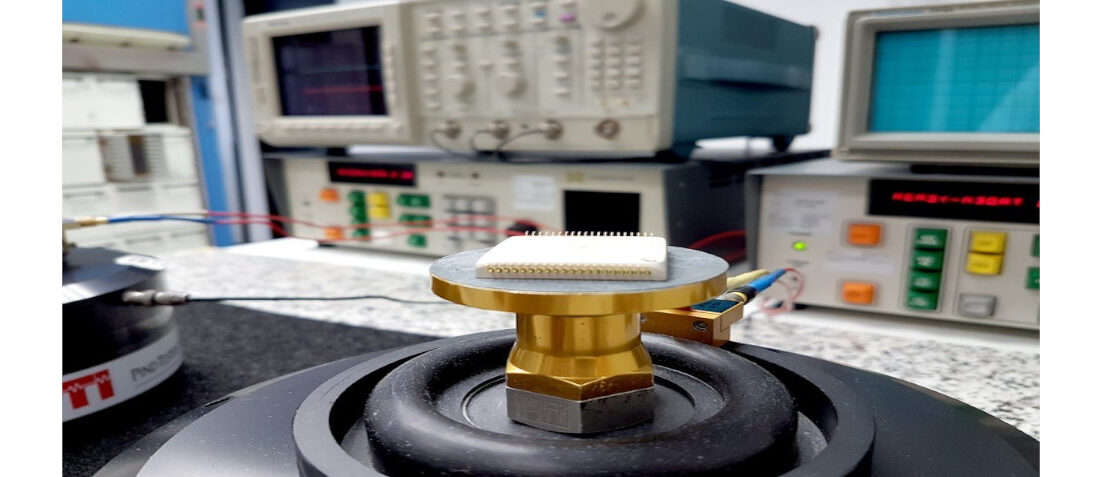

This standard describes the differences and the minimum testing requirements necessary to each of these three classes for evaluation, screening, and lot acceptance. The following test sequence shows the evaluation test sequence for class 1 components, this sequence is the same in the three classes described in the standard with different severity and test conditions to each class.