Soldering Verification of EEE parts SMD and PCBs

- Posted by Mari Carmen López

- On May 16, 2019

- 0

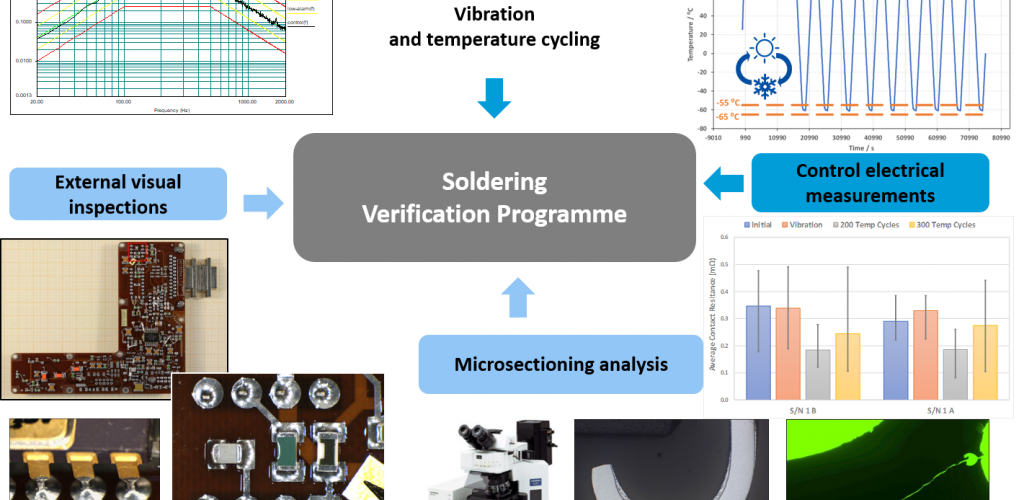

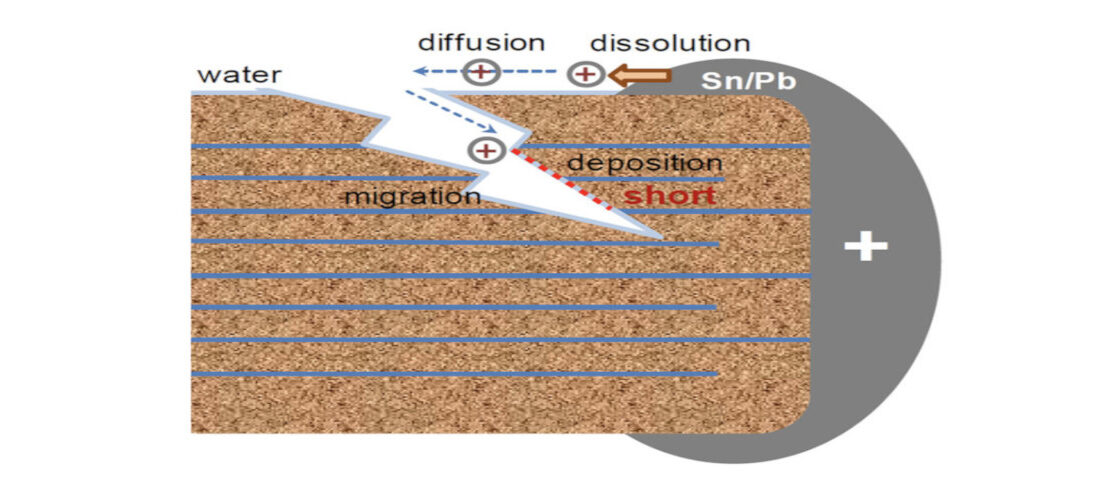

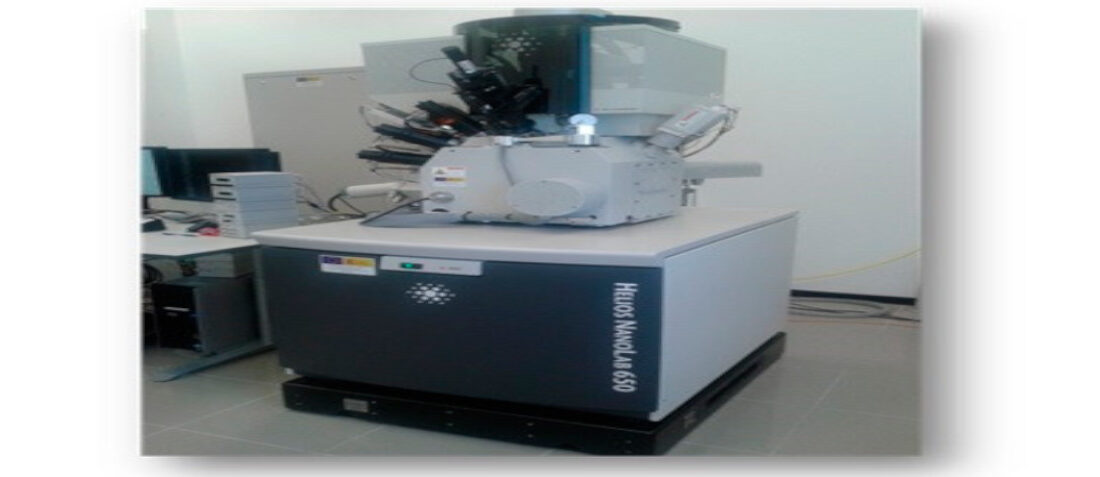

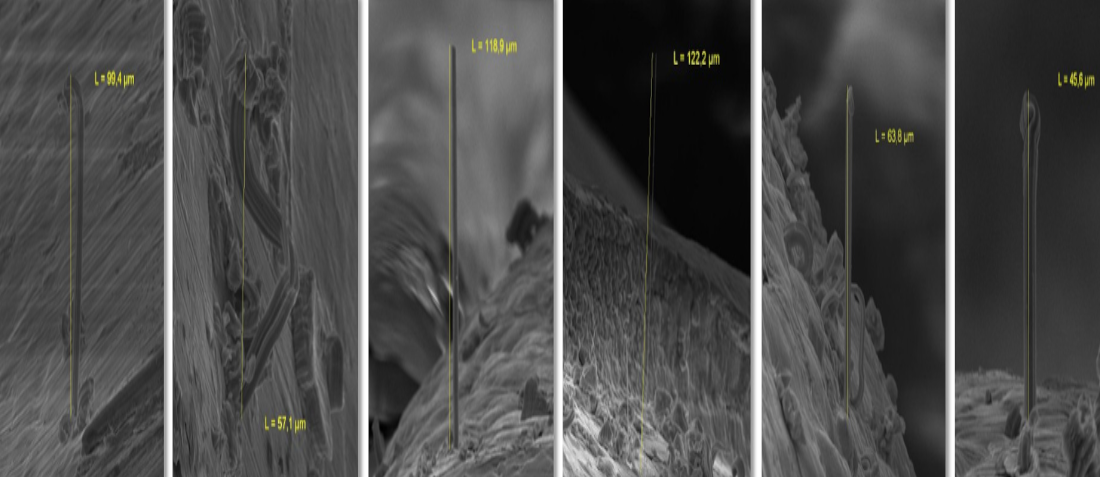

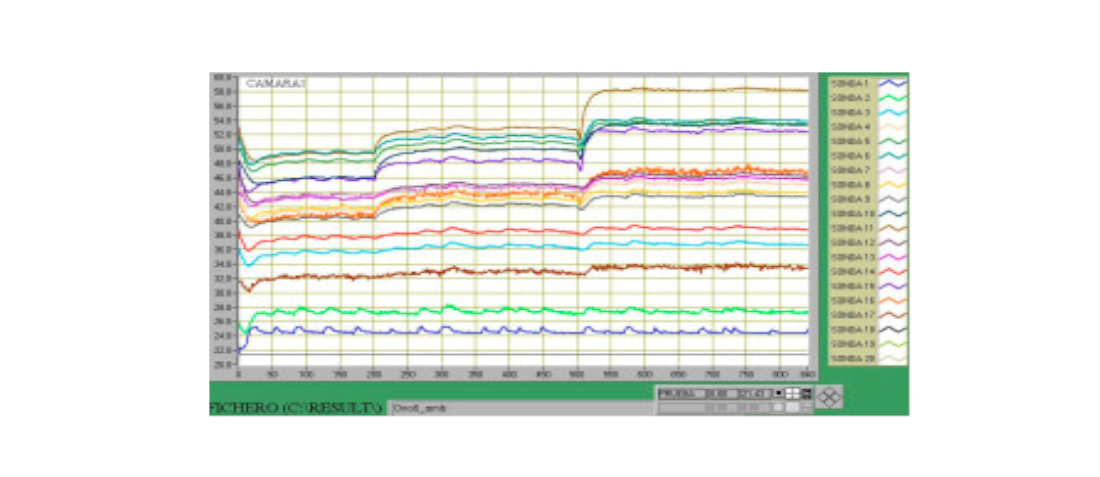

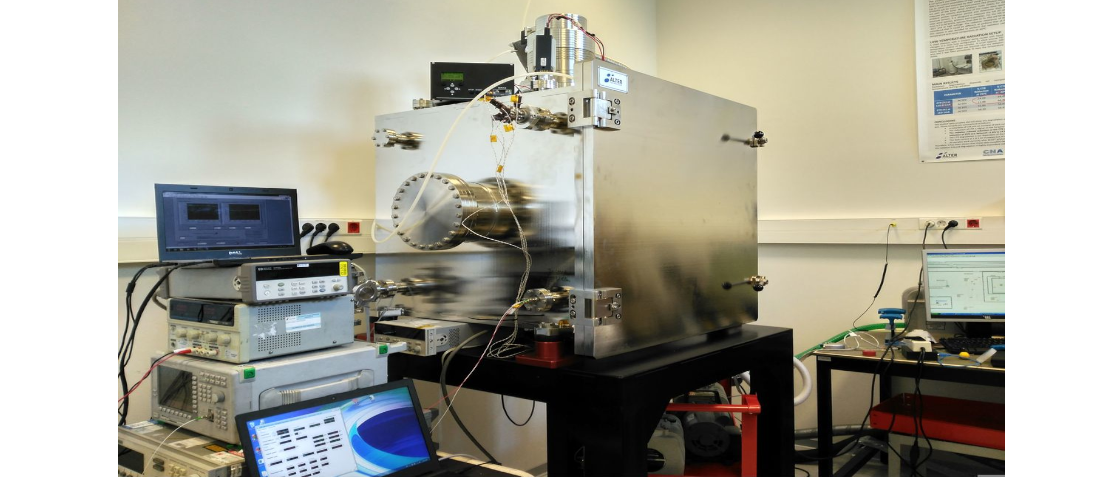

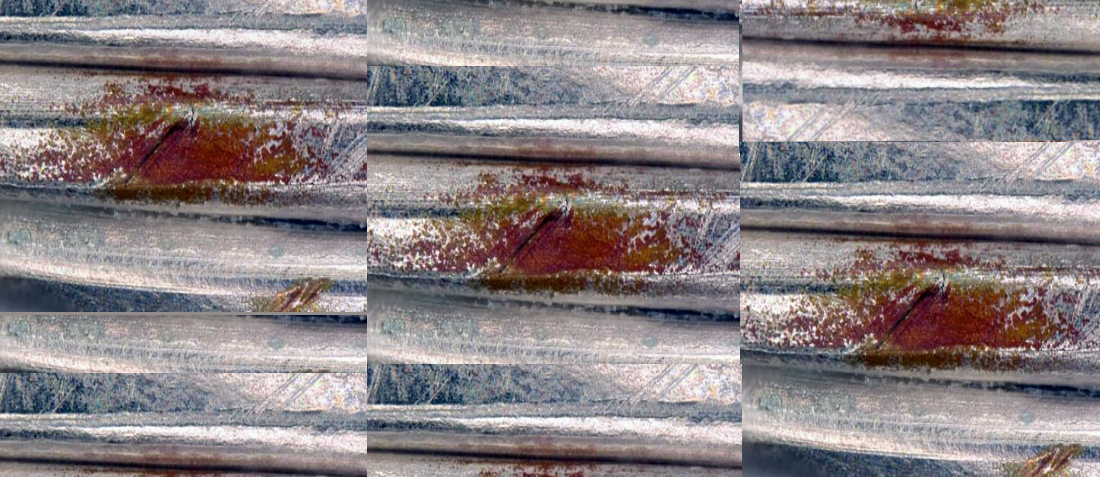

High reliability assembled PCB prototypes as well as novel surface mounted devices (SMD) and mixed systems must be assessed according to well defined qualification test plans. Such high reliability verification programmes are not limited to just evaluate the robustness, reliability and performance of the product but they also address the verification of tools, fabrication procedures and involved materials, as well as the confirmation of product integrity. For instance, ECSS (European Cooperation for Space Standardization” (ECSS) standards used in space programs