Voids on sealing area.

- Posted by Pedro CARABIAS LÓPEZ

- On February 10, 2020

- 0

Voids on sealing area. Observation by X-Ray. Validation by Seal Test.

Would it be enough the sealing material applied at internal area in order to ensure the proper isolation between external and internal environments?

- First point to answer this question:

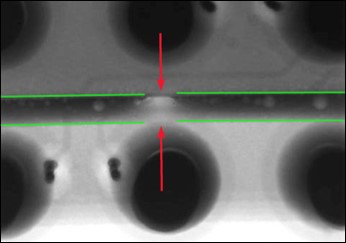

X-Ray inspection is the non-invasive test that allows to assess part construction, where naked eye does not reach.

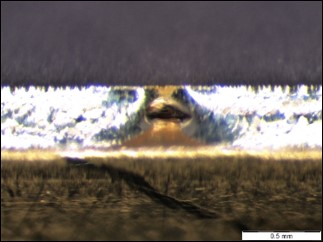

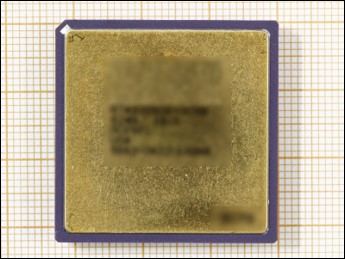

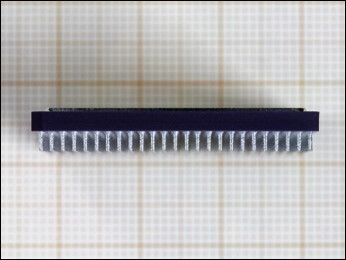

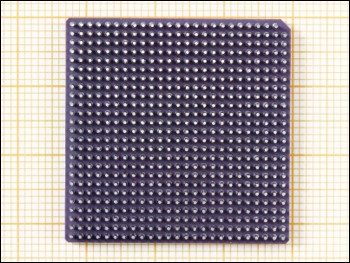

As an example, next images are showing external top, lateral and bottom views that belongs to a microcircuit with CCGA-624 package for space application under evaluation:

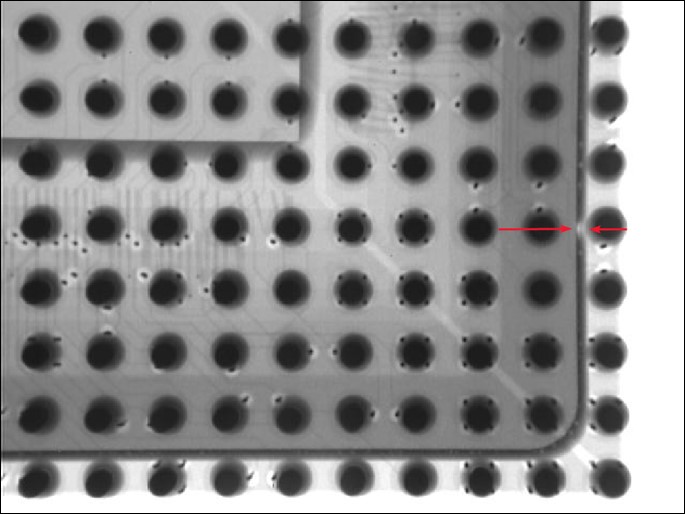

Whereas X-ray image displays the real sealing material applied all around device perimeter:

- Second point:

Seal Test is recommended to be carried out, both Fine Leak and Gross Leak. In this way, although X-Ray discloses a weak point, parts hermeticity will be validated by Seal Test successful outcomes.

Seal Test must be performed according applicable MIL/ ESCC Methods, which depends on each part family:

-

- MIL-STD-883, Method 1014.13 (for integrated circuit components, and other families as specified)

- MIL-STD-750, Method 1071.8 (for discrete families)

- MIL-STD-202, Method 112 (for Tantalum Capacitors with cavity)

- ESCC Basic Specification No. 21100 (test methods, conditions, procedures and requirements specified herein are closely based on hermetic seal tests specified in MIL-STD-750 and MIL-STD-883)

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Outgassing and Mating Test - May 6, 2020

- Quality/reliability issues and detection on High Reliability Optocouplers - April 29, 2020

- Voids on sealing area. - February 10, 2020

0 comments on Voids on sealing area.