A comparison between Red Plague screening methods

- Posted by Manuel Sánchez Ruiz

- On February 1, 2021

- 0

EEE parts designed for Space missions can be often found under the “Hash Environment” label on manufacturers websites. This classification is not by chance, as Space environment provides extreme conditions for performance as no other medium.

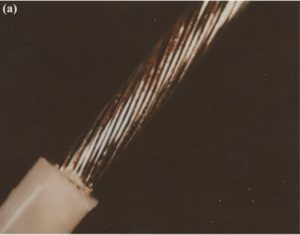

In this sense, Red Plague is problematic corrosion appearing on silver-plated copper conductors. An electromechanical reaction is induced between copper core and silver plating of the conductor (by means of moisture and oxygen present in the silver-copper interface). Wire affected by Red Plague is mechanically compromised, increasing the failure risk linked to severe vibration and shock conditions on space flight. In order to minimize the risk of suffering from Red Plague on conductors, ESCC silver-plated cables are required to have enough thickness of >2um plating. However, this is not the case for Military qualified cables in accordance with DLA specifications, which do not mandatory needs to have this silver-plating thickness and usually only >1µm is required. Even though, still, ESCC conductor generic specification ESCC 3901 includes the Red Plague screening testing for silver plated wires.

Nowadays, discussions are being held between European Space industry, cable manufacturers and agencies to harmonize this requirement and to understand whether Red Plague testing – and how this shall be performed- is an effective test to be performed at screening or qualification level. Furthermore, the quality of silver and how this is deposited over the copper surface seems to have a fundamental role in the appearance of Red Plague with relative independence of 1 or 2-micron thickness.

The Red Plague screening testing used in ESSC specifications system was developed by Anthony and Brown in 1965 and is gathered in the standard ECSS-Q-ST-70-20C. On the other hand, there are two additional methods developed by ASTM International (American Society for Testing and Materials) that are preferred by NASA and widely used on their programs ASTM-B298 & ASTM-B961.

At this point, it is interesting to know: what are the differences and similarities between these methods?

Let’s make a comparison of key points in order to assess this.

Beginning with the objective, ESA ECSS standard is titled as “Determination of the susceptibility of silver-plated copper wire and cable to “red-plague” corrosion”, which actually limits the standard to this problem. On the other side, however, ASTM specifications are titled as “Standard Specification for Silver-Coated Soft or Annealed Copper Wire” (ASTM-B298) and “Standard Specification for Silver Coated Copper and Copper Alloy Stranded Conductors for Electronic Space Application” (ASTM-B961). These two last methods, therefore, cover also other requirements as furnished on temper, elongation allowed, the direction of layers, joints, resistivity, dimensions, characteristics of coating (which involves the Red Plague Corrosion Test), physical and electrical tests, conformance criteria, test methods, packaging and marking. So, here we find the first major difference.

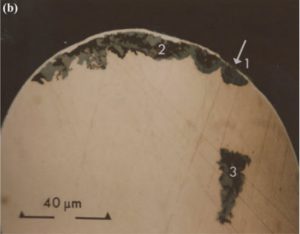

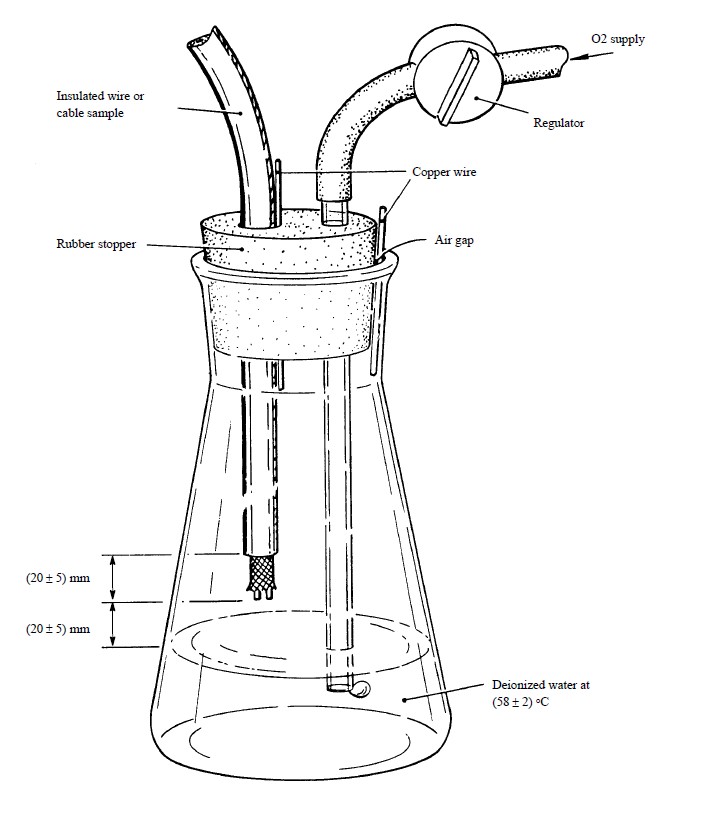

Going down now to the Red Plague Test method itself, we encounter that on ECSS standard, the test samples’ preparation is as follows: 2 adjacent test samples are prepared, each one of 200 +-50mm. The first sample must be stripped-off, and any unusual featured shall be photographed. On the second sample, the one used for the test, insulation is removed on a length of 20+-5mm.

On the other hand, for ASTM-B298, 8 production units shall be selected, and from each one, one specimen of 152mm must be taken. For ASTM-B961, one test sample from each production unit, with a length of 203.2 to 406.4 mm (8-16 in), attached to a polyethene rod. Then, both conductor and rod shall be introduced inside a heat-shrinkable polyethene tubing leaving 20 +-5 mm of conductor exposed.

Test sample for ECSS-Q-ST-70-20C

Regarding the treatment itself, it is quite similar between ECSS-Q-ST-70-20C and ASTM-B961, while it is pretty different in the case of ASTM-B298:

Now the test methods have been outlined, it is time to compare the examination methods or success criteria among the different standards.

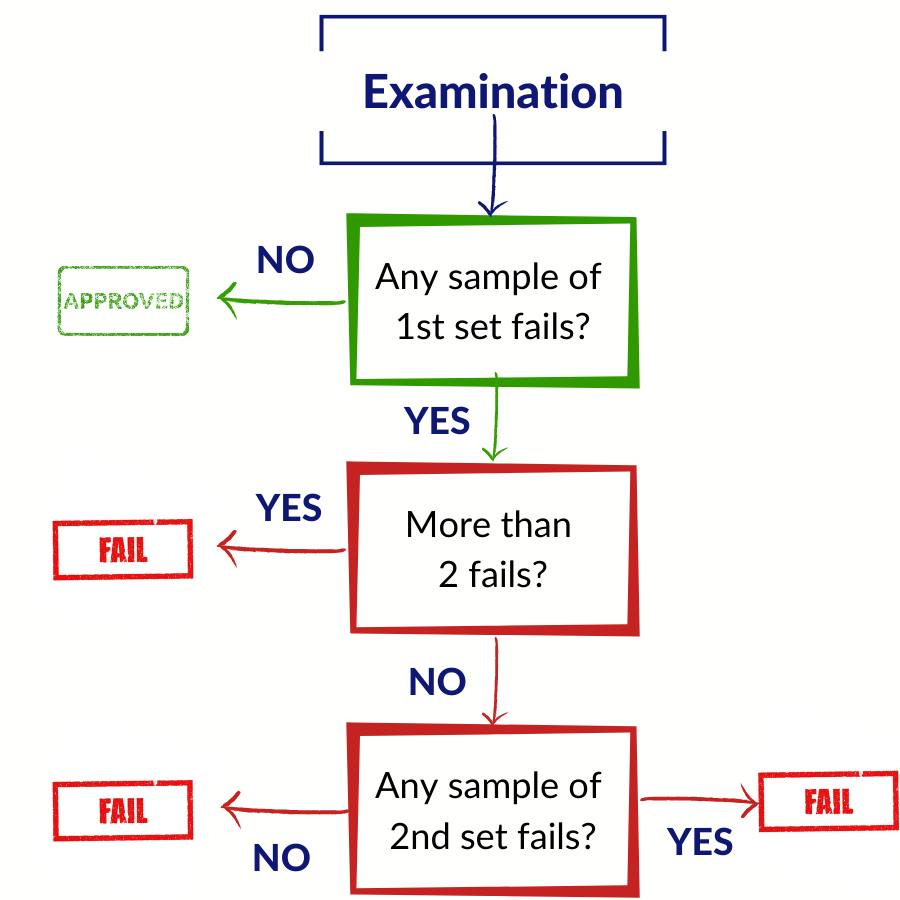

Starting by ASTM-B298, specimens are examined with the unaided eye against a white background. If blackening exposed copper is revealed through openings in the silver coating, samples are considered failed. Blackening within 0.5 in. (12.7 mm) of the cut end shall be omitted. If 1-2 samples out of the 8 fails, testing of 8 additional samples must be carried out, being necessary that all the new 8 samples succeed in the test, to consider that the lot passes the test. If more than 2 samples of the first 8 fail or if any sample of the second 8 fails, the lot is considered to have failed.

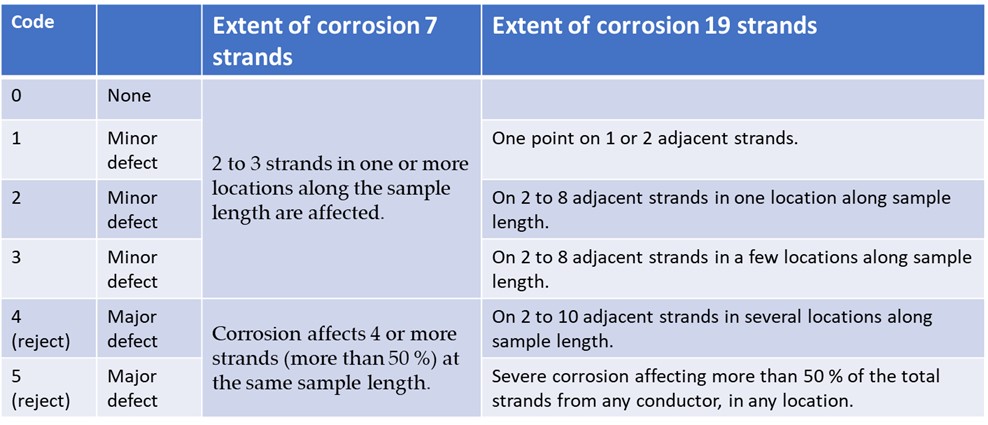

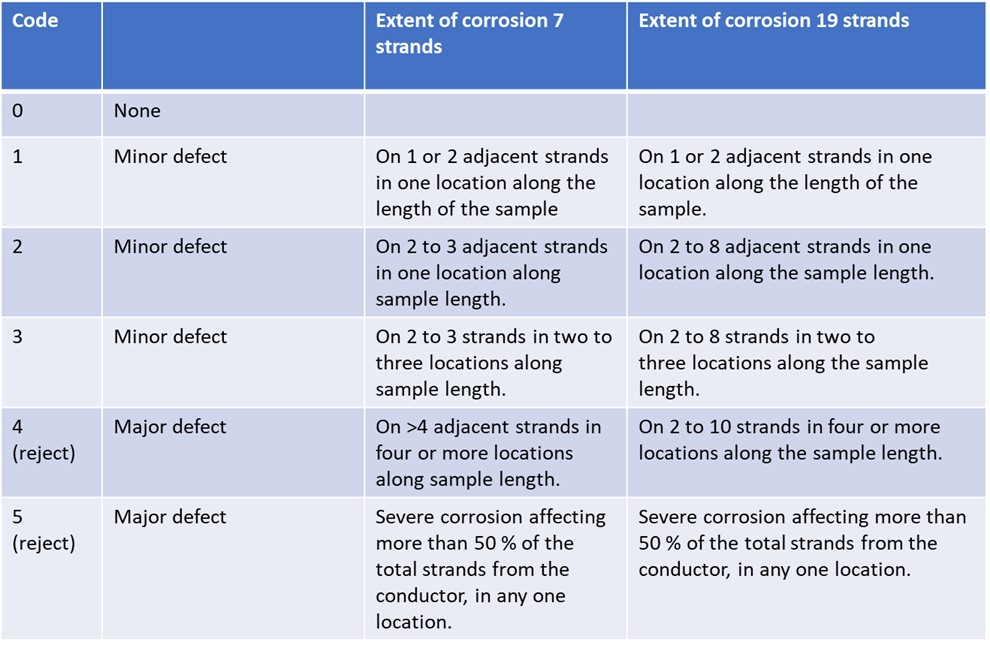

ASTM-B961 and ECSS-Q-ST-70-20C have both success criteria based on an inspection at 20x magnification and establishment of codification of the corrosion on levels from 0 to 5: if samples are codified as 0-3, electrical parameters are not affected and therefore the sample has passed the test, if the sample is awarded codes 4-5, they are rejected. On both methods, the polyethene jacket is removed just after exposure and samples are inspected within 3h after removal from the environment (equipment). Then, where is the difference between the examination of these two methods? On the codification codes!

While in both cases the codification is separated between 7-strand conductors and 19-strand conductors, the description for each case about what is considered a minor or major defect is not exactly the same, even if the approach is similar.

As it can be seen, the main difference lies in the 7-strands conductor case, but we can also see slight details that are not exactly the same on the 19-strands case, as the definition of the number of locations affected in ASTM-B961 standard.

So, in summary, we can conclude that ECSS-Q-ST-70-20C and ASTM-B961 standards are very similar, while ASTM-B298 takes a completely different method.

ALTER TECHNOLOGY offers to our customers all kind of screening/qualification/testing.

Ask our experts to solve any issue arisen during the assembling and mounting of any EEE components in your PCBs and equipment.

Authors: Manuel Morales & Manuel Sánchez

- Platinum Temperature Sensors Solderability Issues - May 27, 2022

- Importance of Alert and Obsolescence Management on Space Projects - February 25, 2022

- What is a PoL converter and when should I use it - November 16, 2021

0 comments on A comparison between Red Plague screening methods