Material Analysis Techniques for Electronic Components

- Posted by Francisco Javier Aparicio Rebollo

- On May 6, 2022

- 0

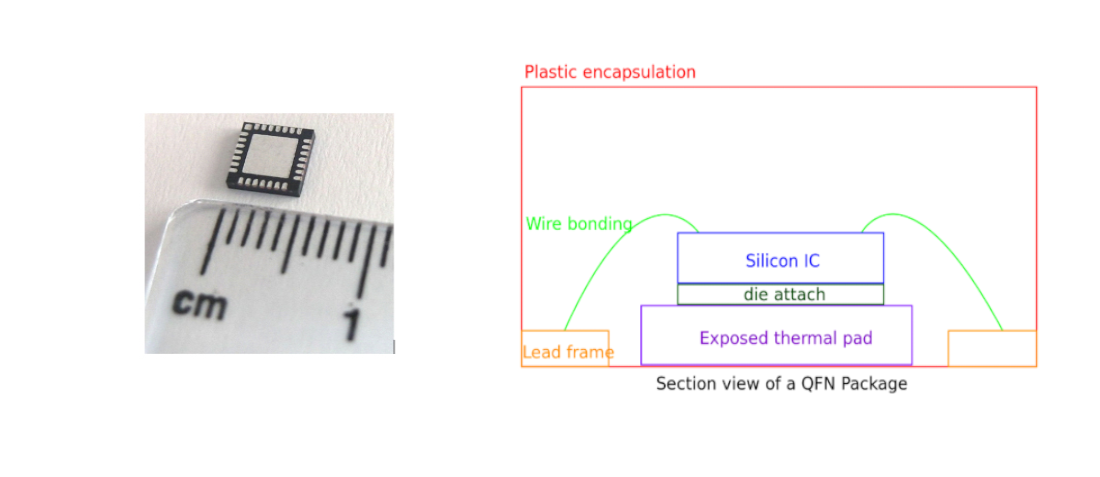

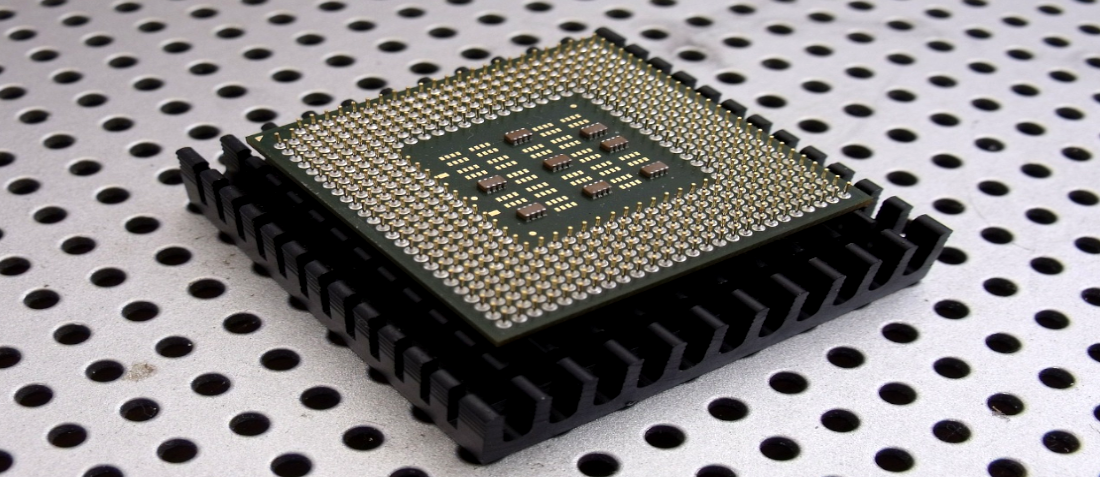

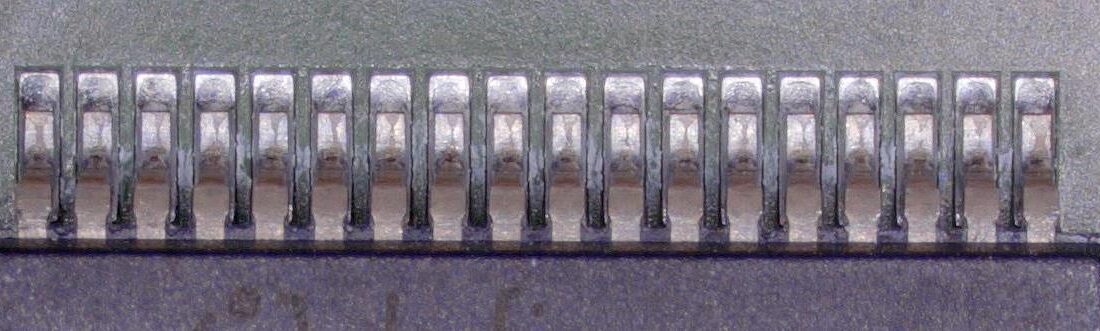

Material Analysis is performed to detect and identify the materials used in the manufacturing of semiconductors and microelectronic parts and packages. One particular use of this analysis is the detection of prohibited materials, especially in the lead finish, to identify potential reliability issues such as undesirable whisker growth caused by pure tin finishes. Lead finish validation for every component type to be soldered is essencial to determine the correct soldering profile.