SAM Capabilities, Analyse the internal structure in EEE Parts

- Posted by Francisco Javier Aparicio Rebollo

- On February 24, 2021

- 0

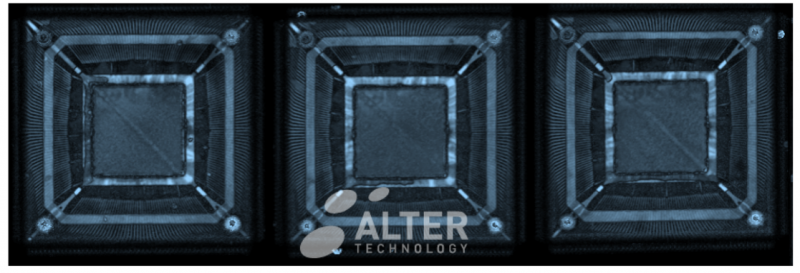

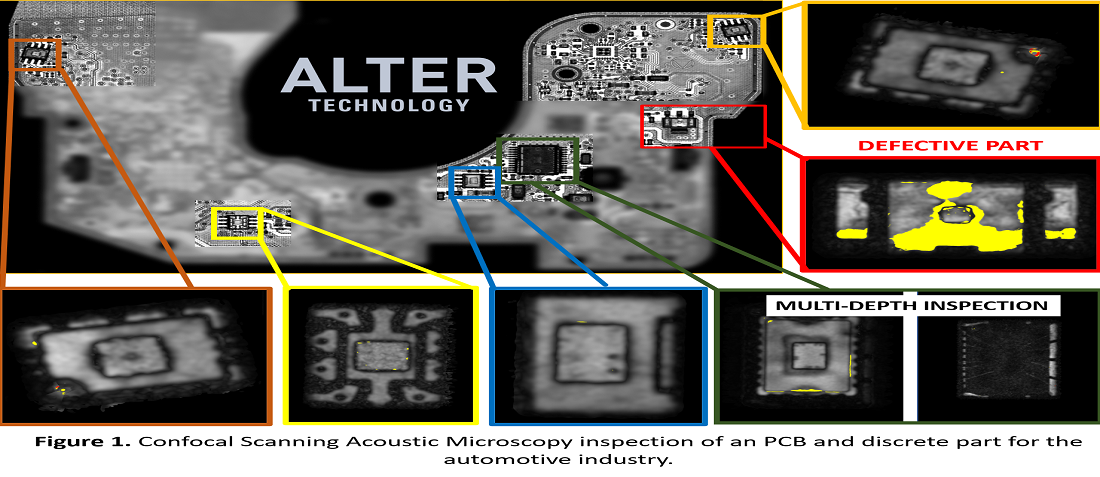

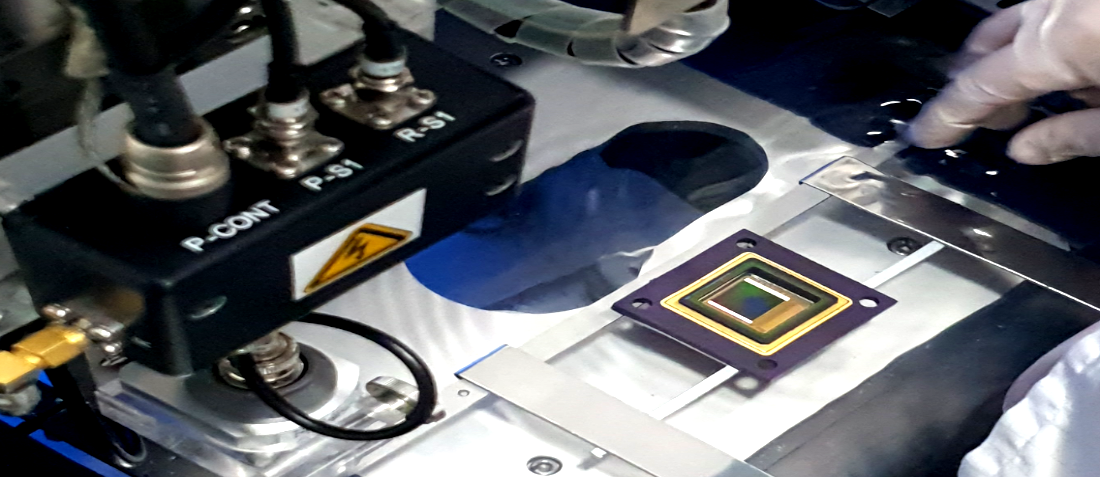

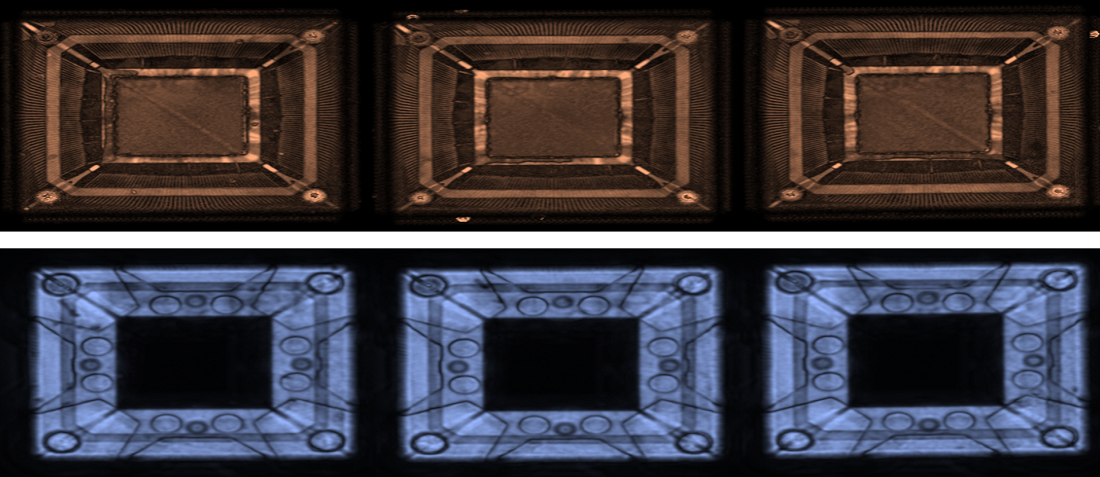

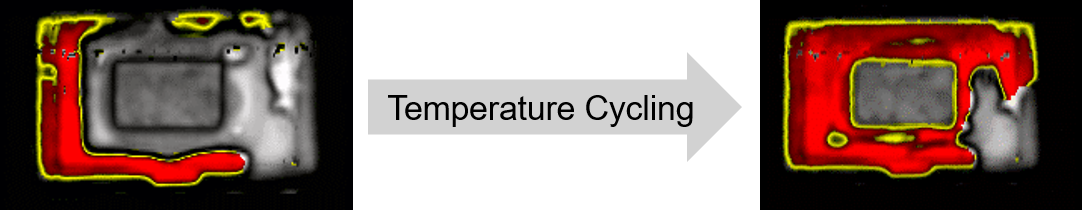

In acoustic microscopy, resolution and inspection depth is an inversely related parameter that depends on the probe frequency and the characteristics of the involved materials. Therefore, the inspection frequency must be carefully selected in order to optimize the accuracy without decreasing the inspection depth below the specimen thickness. Suitable selection of the inspection parameters provides:

Detection of ultra-thin (submicrometric) delamination in multilayer systems.

Micrometric lateral resolution. In acoustic microscopy, resolution and inspection depth is an inversely related parameter that depends on the probe frequency and the characteristics of the involved materials.