What is RFID? How RFID works? Video Explained

- Posted by doEEEt Media Group

- On August 10, 2022

- 0

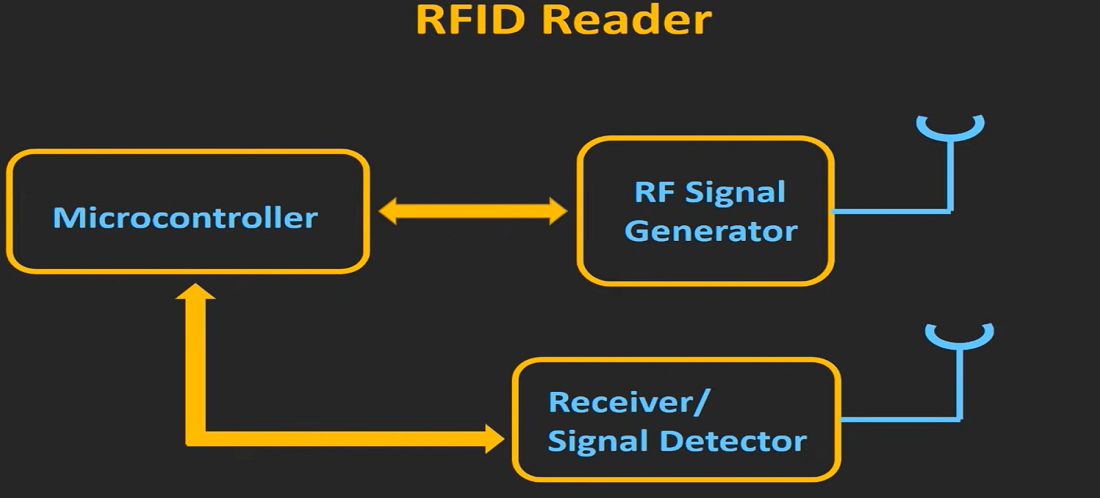

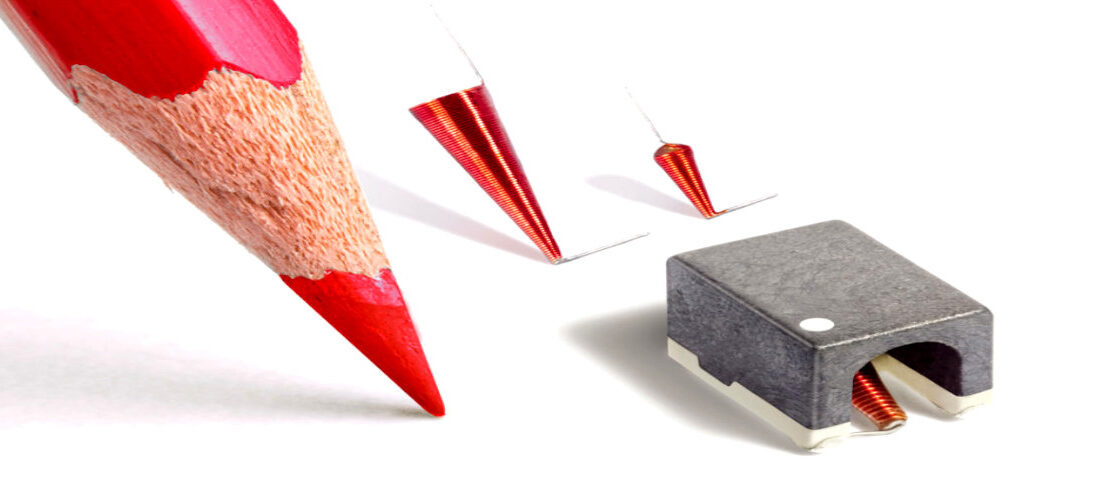

RFID is a technology that works on radio frequency and is used to auto-identify different objects. The RFID system mainly consists of two parts.