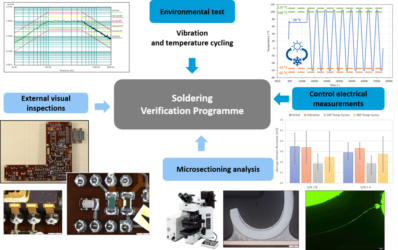

The requirements about WHEN to perform a DPA on many EEE components are established in documents like ECSS-Q-ST-60C and ECSS-Q-ST-60-13C for commercial EEE components… and/or at the project level.

The requirement about WHAT to do and HOW are included in documents like Generic Specifications, ESCC Basic Specification No. 21001, MIL-STD Test Methods, NASA EEE-INST-002, NASA PEM-INST-001…

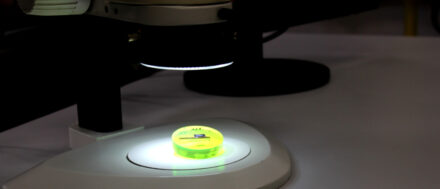

ALTER TECHNOLOGY has an accumulated experience in DPA on EEE parts and PCB micro sectioning, being a fully accredited laboratory by ESA.

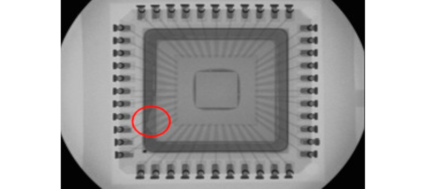

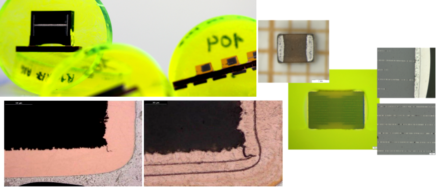

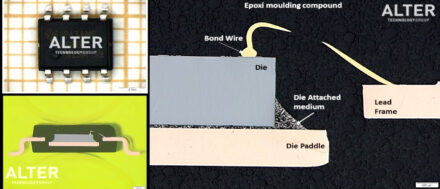

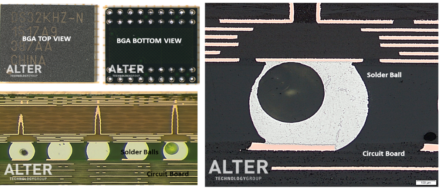

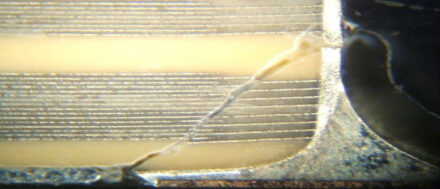

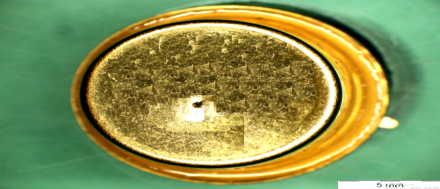

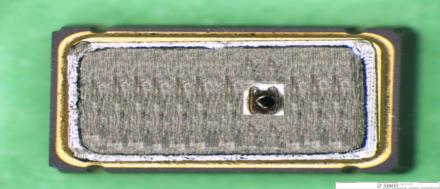

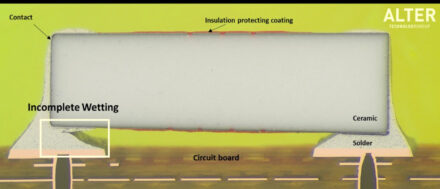

Microsectioning or Cross-sectioning is a failure analysis technique (performed during DPA) for mechanically exposing a plane of interest in a die or package for further analysis or inspection. It usually consists of sawing, grinding, polishing, and staining the specimen until the plane of interest is ready for inspection by optical or electron microscopy.

Components are microsectioned after potting in suitable epoxy resin so that a microscopic examination can be undertaken for the purpose of accurately locating, identifying and characterizing all the internal structural features of the samples in order to judge any defects against the criteria of the specification.