Nano Dimension Presents Production-Grade Printed Capacitors for PCBs

- Posted by doEEEt Media Group

- On November 6, 2021

- 0

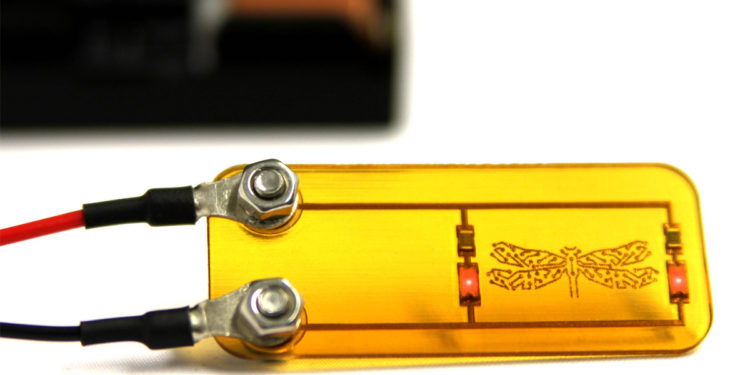

Nano Dimension Ltd., a leading additive electronics provider for electronics, announced that it has developed 3D printed capacitors with the Company’s pioneering DragonFly additive manufacturing system. These capacitors are embedded in the body of the additively manufactured printed circuit boards (PCBs), saving space and eliminating the need for assembly.