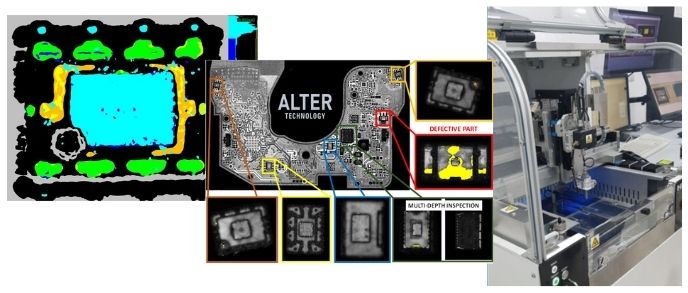

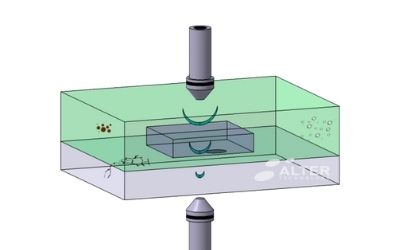

What is C-SAM? Scanning acoustic microscopy (SAM), also denominated acoustic micro imaging (AMI), and scanning acoustic tomography (SAT) is a consolidated and recognized tool for quality control, inspection, and failure analysis of microelectronic components and materials.

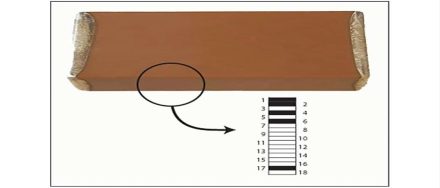

Among other types of failures, acoustic techniques are particularly suitable for detecting those irregularities involving materials and density changes, including delaminations, voids, porosity and cracks, in any EEE components.

Therefore this NON-DESTRUCTIVE testing method is included in different EVALUATION, SCREENING, and LOT VALIDATION flows for several families of EEE components, which can be found in the doEEEt platform.