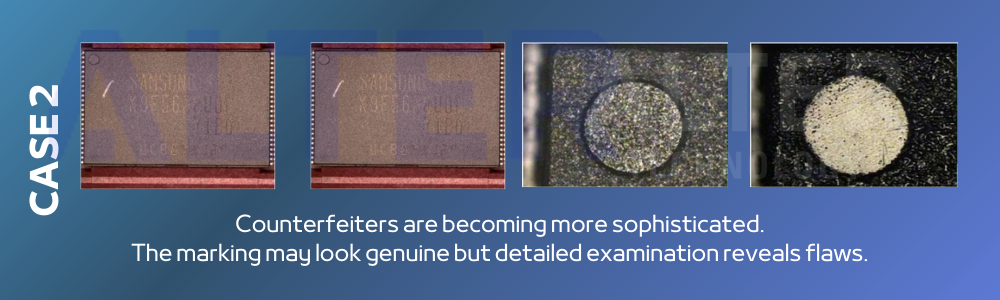

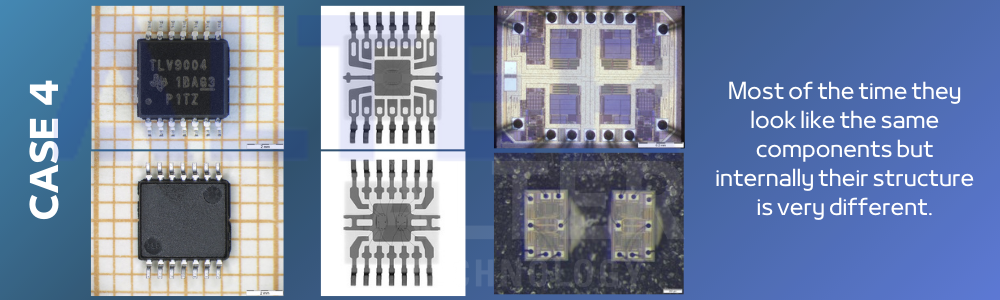

Counterfeit electronic components are substitutes or unauthorized copies of a product in which the performance or the materials used have been changed without notice.

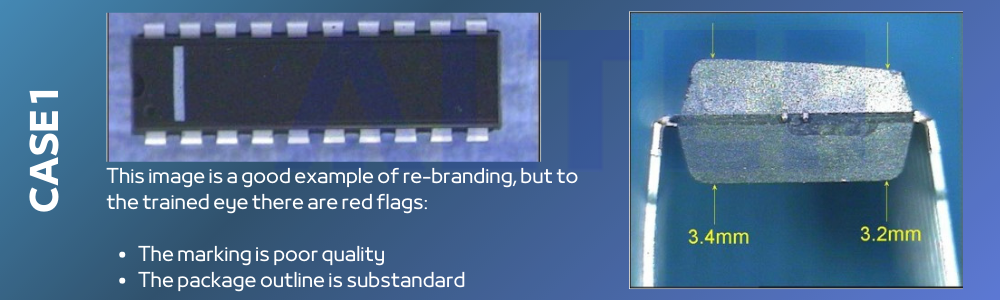

They are also items that are deliberately altered in such a way as to misrepresent the actual quality of the item with the intent to defraud or deceive the purchaser.

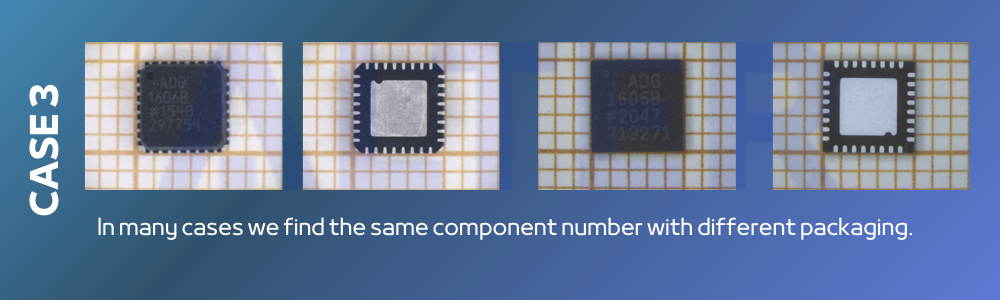

The wider use of lower-cost parts, as well as non-verified procurement channels, are spreading the problem, being also prevalent in the medical and space markets. A growing number of fraudulent and/or counterfeit electronic parts are entering the supply chain, especially when purchasing parts from other than original component manufacturers or their authorized agents.