Vacuum system, temperature and pneumatic system

- Posted by doEEEt Media Group

- On February 15, 2022

- 0

The verification of the correct behavior of a switch has been carried out during half a million on and off switches. The conditions of this test made the realization difficult since they had to be done under conditions of the vacuum system of space, that is, the pressure was below 10E-5 mbar, and the temperature was below -170ºC. For this, a vacuum chamber is used that lowers the pressure by a turbomolecular pump that can reach up to 50,000rpm and works like an airplane turbine. The temperature is achieved thanks to introducing the entire system into a cryogenic chamber that uses liquid nitrogen for cooling.

Vacuum system and Pneumatic system

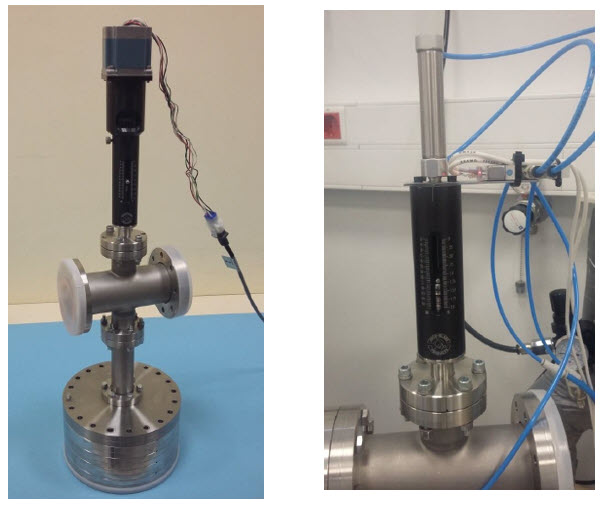

To carry out this test, it was necessary to use linear feedthrough that would allow us to operate a mechanical arm that would press the switches from outside the space simulation chamber. For them, a mechanical positioner with an endless screw was used first, but the low temperatures and pressures caused the system to fail. For this reason, it was decided to use a pneumatic system adapted to the system that allowed us to carry out half a million interactions without problems.

Figure 1: Vacuum chamber with mechanical positioner in the left and pneumatic system at the right

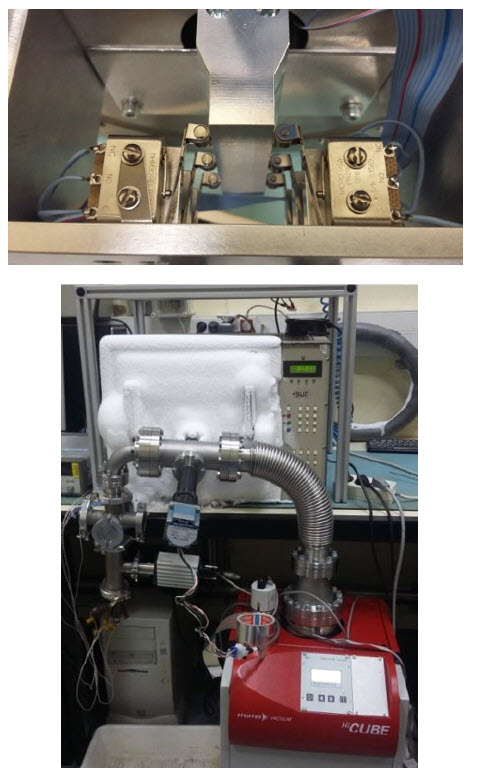

In addition to the design of the mechanical parts, a part was also developed to simulate the interaction as close to how it would be once integrated into the system, a titanium part was designed which was the one that transmitted the pressure to the switches.

Figure 2: On the left, we can see the samples in the system designed for the test. On the right, you can see the complete system with the vacuum system

The control of the vacuum system, the temperature and the pneumatic system were controlled by a program of a LabVIEW made for the test that synchronicity all the system.

The electrical characterization

The electrical characterization of the System consisted of being able to measure the continuity and non-continuity of the switches when they were open and when they were closed. To do this, a Hp349070A communication matrix was used to determine if any of the switches were open or closed. We used a Keithley2410 power supply to monitor the consumption of the channels to decide on their correct operation.

At the beginning and end of the test, we did a visual inspection to see that the switches were not degraded.

Mechanical characterization

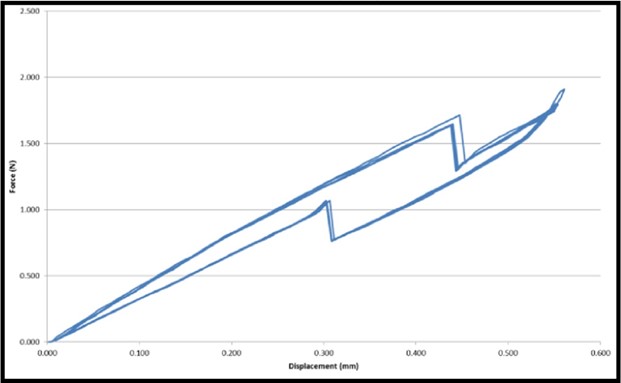

The most important thing about a test and seeing that the system works is also knowing if it has suffered any degradation. In a mechanical system, it is very difficult to know if there is any difference in behavior before and after the test. For this reason, for the evaluation of the mechanical behavior of the switches, a system was designed through a strain gauge.

Figure 3: Mechanical characterization setup

Programing a material testing machine of Ametek, we did a force-displacement characterization of the difference between when you turn on the switch and when you turn off. It was observed that there is a difference in the behavior when it is turned on compared to when it is turned off, resulting in a cycle of stress. This cycle of stress was used as a reference to observe changes in the mechanical behavior of the sampling mechanism. In a final evaluation of the extension, we can see that there are no differences in the switches’ behavior after the test.

Figure 4: Mechanical characterization graph

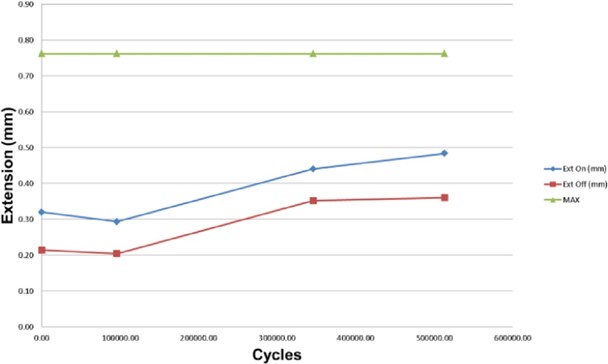

Characterization of half million of On/Off of mechanical switches in vacuum system and -170ºC: Test results and conclusions

The most relevant result of this work is that all tested samples passed the satisfactory test without pertinent changes to the measured parameters. We can observe an increase in the mechanic’s resistance but under the maximum limit.

Figure 5: Evolution of the mechanical force of a sample

GET IN TOUCH TODAY!

Want to contract this service? Contact us!

- Miniature RF Connectors - April 29, 2025

- Miniature RF Connectors for high-performance testing - April 24, 2025

- Space-Grade components available for immediate delivery - April 10, 2025

0 comments on Vacuum system, temperature and pneumatic system