Doing Incoming Inspection to identify potentially non-conforming parts

- Posted by Antonio José Rey

- On May 20, 2020

- 1

Incoming Inspection

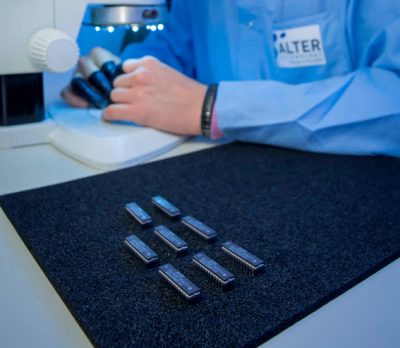

The purpose of the incoming inspection is to identify potentially non-conforming parts, prior to placing the material in the inventory or moving it to the production flow. All parts and materials subject to receiving inspection are examined in accordance with customer purchase order requirements, drawings and standards, among others.

External Visual Inspection as a part of the Incoming process

During the receiving process all raw materials are inspected and verified by reconciling the purchase order requirements with the packing slip provided by the supplier. Statistical analysis is the preferred method of performing receiving inspection. Receiving inspection may be omitted if the supplier has been established as a certified vendor per requirements.

Incoming inspection for the materials undergoes it all necessary and tests to ensure their conformance to the requirements. Upon acceptance, the inspector signs off the job card and enters the results in the inspection log. If at any time parts or materials are rejected, the person rejecting the material issues a problem report. The gold copy of the problem report is placed with the rejected items and the items are segregated. All materials remain in the holding area until, upon acceptance by the customer, the designated quality representatives determine whether the materials are acceptable, reworkable or scrap.

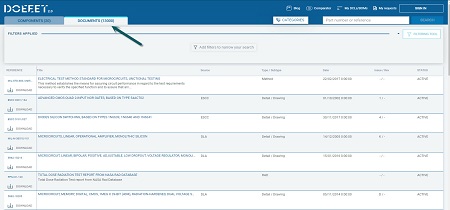

Documentation review process

The Incoming inspection process may include the following:

- External visual inspection

- Weight and dimension check (upon request)

- Documentation review

- Checking the Certificate of Compliance

- Reviewing lot screening records and checking PDA/Lot failure criteria

- Checking radiation results

- Checking LAT/QCI results

- Radiographic Inspection

- Hermeticity Leak Testing

- PIND test

- Pure tin control

- Material Analysis

- Electrical Measurements

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Doing Incoming Inspection to identify potentially non-conforming parts - May 20, 2020

- C-SAM: Crack detection within plastic packages - May 8, 2020

1 comments on Doing Incoming Inspection to identify potentially non-conforming parts