Lunar Regolith Test onto COTS Optoelectronics

- Posted by Juan Moreno Echarri

- On January 18, 2023

- 0

Introduction:

The use of COTS in space is nowadays a reality, and Optoelectronics is not an exception. In the case of LEDs, technological improvements and new development turn them into the best option (or even the only option) to address a technological problem.

This quick evolvement of the devices enhances the typical problems of COTS. Making lots of changes quickly in specs due to improvements in technology, making harder to get traceability from the manufacturer and retailers. These are also many times high-performance but not high reliability and were designed to withstand terrestrial conditions but not space.

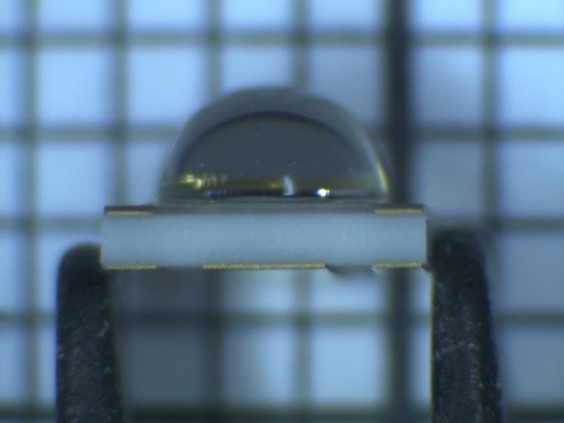

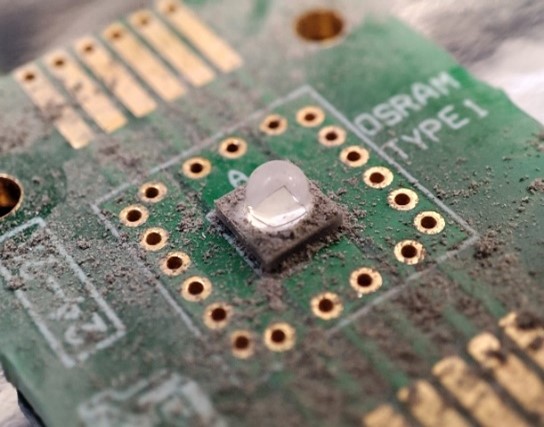

Figure 1. Example of SMD Globtop package

Introducing the usage in planetary exploration as illumination of surface in robotic lunar exploration needs new testing techniques. Commercial LEDs are available in many packages, most SMD mounting and, in many cases, finished with a silicone glob top, as shown in fig.1. The degradation caused by lunar regolith exposure onto all these options is unknown and shall be assessed by testing.

This paper presents and explains the regolith test setup developed by ALTER. Design and development of the test setup have taken into consideration not only the requirements of the regolith test itself but the necessity of being compatible with the remaining tests necessary to be performed onto the same part types for ECSS-based space qualification.

Test considerations and results:

The test setup design and method aimed to obtain most realistically the exposure of LEDs to lunar regolith while biased in vacuum conditions. However, many other considerations had to be taken into consideration to obtain as much information as possible and be compatible with many other space-grade tests to be performed in other samples of the same LEDs keeping reasonable costs and time scales.

- Exposure of the LEDs to lunar regolith will occur in operating conditions. Need to bias certain devices with currents as high as 1.5A. Not only electrical powerthrough vacuum feedthroughs shall be addressed, and thermal management inside the chamber because of heat dissipated.

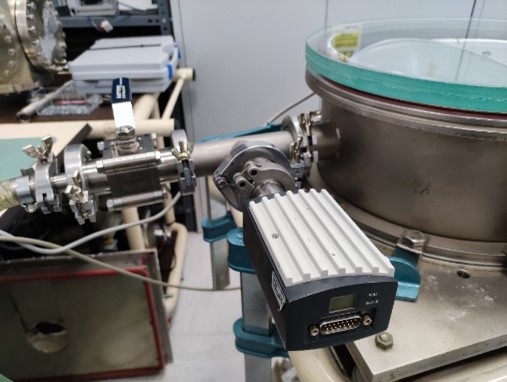

Figure 2. ATN test board with central footprint customized for each type of LED

- Samples shall be tested in lots of several samples to keep testing time and cost at a minimum while ensuring good homogeneity of the results.

- DUTs are SMD packages that shall be mounted onto boards to be handled and biased, as shown in fig.2. To allow correct heat management, each manufacturer’s footprint, and mounting instructions shall be used. These boards shall be compatible with the same characterization and regolith test setup to test many samples without modifying test setups.

- Together with electro-optical characterization, mass measurements will be performed to evaluate the amount of regolith attached to the samples. Samples shall be singulated to allow single sample measurements and mass measurements. Biasing shall be performed in a way no mass is added nor removed to the single LED board, so no wires o weldings are possible.

- Electro-optical characterization of the samples has to be performed at room temperature before the regolith test. Also, mass (sample +individual board) is weighed using a 0.1mg accuracy system.

- The correct electrical connection of the samples inside the test setup shall be checked before any regolith is put in place (fig.3). Then, enough lunar regolith shall be placed in the specific area of the test setup. The quantity of regolith impacts not only the quantity deposited but also the homogeneity of the deposition. This effect shall be carefully evaluated when several samples are tested at a time.

- A vacuum gauge shall be implemented in order to verify that the pressure level is not changing during the test due to any lack of hermeticity of the setup (might be caused by lunar regolith itself in o-rings or similar) as shown in fig.4.

- Since the test shall be performed in representative conditions, samples shall be electrically biased a while in advance to the test with nominal current values until thermal, and hence, voltage stabilization is achieved, and voltage monitoring stabilization shall be achieved.

- Devices are removed from the regolith setup and weighted before the electro-optical characterization to correctly evaluate the quantity of dust attached.

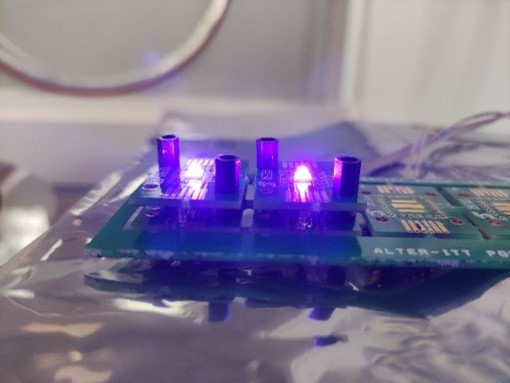

Figure 3. Blue LEDs biased on using the setup test board with spring contact connections

Figure 4. Vacuum gauge for pressure monitoring

GET IN TOUCH TODAY!

Do you have questions? Contact us!

- Lunar Regolith Test onto COTS Optoelectronics - January 18, 2023

- SiC reliability: Defects detection test for SiC devices - October 26, 2022

- Testing SiC Schottky Diodes for Heavy Ions Optimization - August 9, 2022

0 comments on Lunar Regolith Test onto COTS Optoelectronics