Needs and requirements of COTS at Inmarsat

- Posted by Kristiina Jokela

- On December 3, 2019

- 0

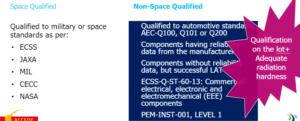

EEE Parts Selection

Screening

Any EEE component shall be screened as

Screening can be reduced if:

- No impact on reliability

- Removed step is ineffective

- Manufacturing is well controlled

No additional screening for complex components!

Lot Acceptance Test (LAT)

Necessary for EVERY non-qualified part (Each datecode or tracecode)

- LAT as per ECSS, MIL or AEC-Q200

Or

- Custom-made LAT, including following verifications in:

-

- Construction analysis

- Mechanical environment (shocks, acceleration, vibration),

- Highly Accelerated Stress Test (HAST)

- Thermal cycling

- Lifetest

- Radiation

-

Radiation verification

Requirement unchanged

Radiation analysis

- RADLAT

TID

- Margin > 2

- Margin >1.2, if data on the lot

SEE

- SOA verified

Radiation verification necessary.

Testing required if data not available

Parts Procurement Control Boards

Inmarsat approves all parts in as-design phase

Space qualified parts approval

- Listing in DCL

Non-Space qualified parts approved

- Listing in DCL

- Justification document detailing

-

- Technical description of the part

- Heritage use

- Specifications, LAT, Screening, procurement

- Planned radiation tests or demonstrated radiation capabilities

-

Inmarsat approves all parts in as-built phase

Review

- That LAT and planned activites has been performed on mounted DateCodes

- Relifing

- NCR’s, RFW’s

Note

- Non-conformances related to qualification or procurement are to be processed in NRB’s

Relifing

Max lifetime 15 years

Parts which are older than 15 years at time of assembly shall not be used.

Relifing activities are not required during the 15 years timeframe.

- Parts storage in adequate storage conditions

- Advantageous for

-

- obsolesce management, strategic stocks (radiation tested), long delivery time, heavy lot charges, long production cycles.

-

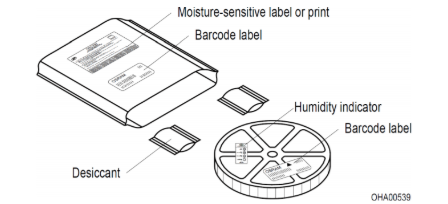

Storage

Commercial parts encapsulated in plastic package shall be stored:

- Under Nitrogen, or

- under dry and ionised air (RH shall be kept to 20% maximum), or

- In dry packs

Derating

Parts Stress Analysis

Derating rules to be respected in order to keep the reliability along the mission

-

- The ECSS-Q-ST-30-11(latest version) or

- NASA EEE-INST-002, or

- corresponding MIL specification

Stresses to be calculated as per real application

- Needs and requirements of COTS at Inmarsat - December 3, 2019

0 comments on Needs and requirements of COTS at Inmarsat