C-SAM: Crack detection within plastic packages

- Posted by Antonio José Rey

- On May 8, 2020

- 0

Summary

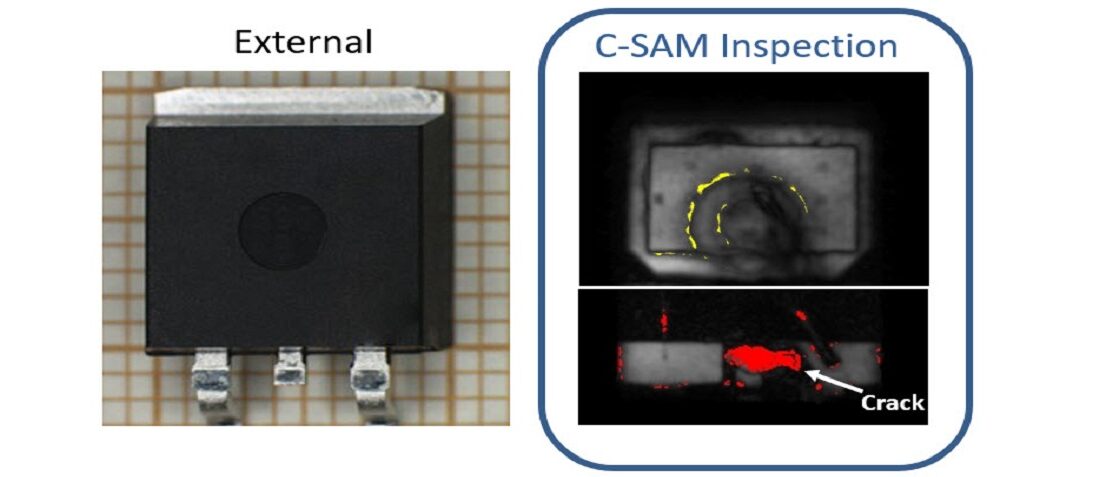

Package crack/void between non-connected terminals is a critical anomaly in plastic encapsulated parts. This is so as these can turn into a conductive path and lead to catastrophic failures. In this regard, Scanning Acoustic Microscopy (SAM) is the most effective non-destructive approach for the sensitive detection of such deviations within plastic packages. The present note shows the comprehensive inspection of a thick power transistor and the detection of this type of internal anomalies.

Sample & Method

The images show the confocal scanning acoustic microscopy (C-SAM) inspection of a power transistor specially designed for hard switching SMPS topologies. Similarly to other power transistors, the device features a thick plastic package (TO-263). Thus an appropriate transducer/frequency must be specifically selected for the comprehensive inspection of the systems and to reach the required quality and definition.

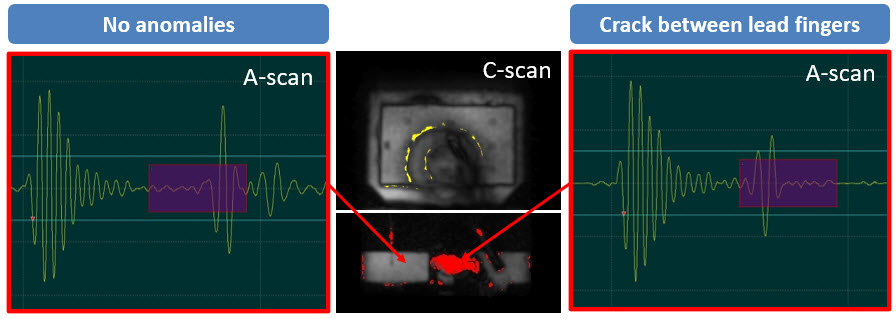

In such a thick package a multi-depth inspection approach is selected to confocally resolve micrometric cracks thanks to the C-Scan-mode of the acoustic microscope. This inspection process is conducted i.a.w. the acceptance/rejection criteria indicated in the applicable inspection methods (J-STD-020E, ESCC 25200, PEM-INST-001 & MIL-STD-1580).

Remarks

C-mode scanning acoustic microscopy discloses a rejectable crack that extends the whole length between at least two terminals. In this case, the image was optimized to register the crack.

The A-scan below shows clear phase inversion sings (right) that contrast with the normal-positive peak detected on a defect-free lead finger (left). Such a type of anomaly is considered a cause of rejection according to different test methods. This is so as the detected crack can open a conductive path between lead-frame-fingers designed to be isolated, which compromises the reliability and the suitable performance of the device.

Contact us

- Doing Incoming Inspection to identify potentially non-conforming parts - May 20, 2020

- C-SAM: Crack detection within plastic packages - May 8, 2020

0 comments on C-SAM: Crack detection within plastic packages