ALTER TECHNOLOGY offers its customers the most appropriate handling and storage conditions to avoid any damage or contamination of the EEE parts.

- Full control of the humidity and temperature conditions 24/7, 365 days a year (22ºC +/- 3 ºC; 55RH% +/- 10 ºC), preventing the undesirable effects of oxidation or ESD (Electro Static Discharge).

- – Nitrogen storage, it can be directly in a dry cabinet or MBB (Moisture Barrier Bags) filled with nitrogen, adding desiccant bags and moisture indicators.

- Powerful software, allowing quick access to EEE parts location.

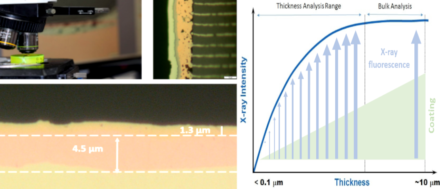

On top of that, ALTER TECHNOLOGY offers its customers the relifing activity based on ECSS-Q-ST-60-14C, which allows validating the usability of the EEE components when the time period from the manufacturing date to the PCB assembly date exceeds a certain number of years.

If by any chance the component is obsolete and you need a replacement, doEEEt allows you to find the closest market alternative.

EEE components can undergo a certain degree of degradation during storage, mainly caused by unfavorable storage conditions or improper storage or handling. The relifing process aims to detect any latent or patent degradation in the product performance that could directly affect the system performance or pose a specific long-term threat.

The commonly used Europe ESCC standard ECSS-Q-ST-60-14C specifies the relifing requirements and the activities to be performed on products that have been stored for a long time. The test sequence defined in the standard has been optimized to obtain maximum confidence in the test results with a limited set of inspections. It can be summarized as follows: