DPA Test for Hall Effect Sensors

Destructive Physical Analysis (DPA test) is a systematic, logical, detailed examination of EEE parts at various stages of physical disassembly. This activity is performed in order to verify that the manufactured lot quality is in accordance with the detailed specification and project requirements. Anomalies and defects detected through DPA could cause degradation or failure of the system in which the devices are to be employed. >> Read more

EEE Parts Results Page

DPA Test for Hall Effect Sensors

Destructive Physical Analysis (DPA test) is a systematic, logical, detailed examination of EEE parts at various stages of physical disassembly. This activity is performed in order to verify that the manufactured lot quality is in accordance with the detailed specification and project requirements. Anomalies and defects detected through DPA could cause degradation or failure of the system in which the devices are to be employed. >> Read more

EEE Parts Results Page

33 results found for Hall Effect/IC Sensors/Microcircuits

Part reference

Quality level / QPL

Package

TID (krads)

SEE (MeV/mg/cm2)

Unit price

Lead time

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

CLASS S EQ

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

HIGH RELIABILITY

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

CLASS S EQ

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

CLASS K EQ

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

CLASS B EQ

Not qualified

NOT LISTED IN QPL

Through Hole Mount

Similar TO-92

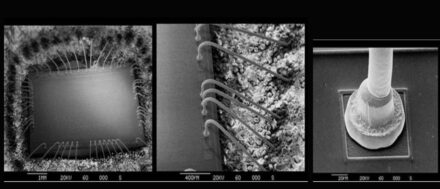

Part validation activities

Cost & Activity Matrix