Cross Sectioning for Thermostatic Switches

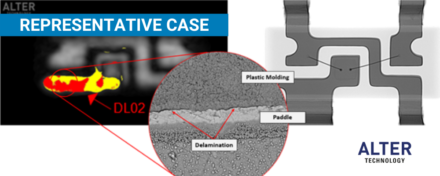

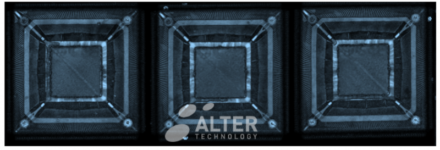

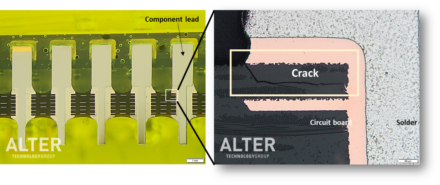

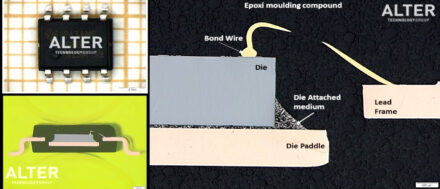

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

Cross Sectioning for Thermostatic Switches

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

76716 results found for Thermostatic/Switches

Part reference

Quality level / QPL

Package

Contact Configuration

Nominal Operating Temperature (Opening Contact)

Nominal Restoring Temperature (Closing Contact)

Rated Current

Unit price

Lead time

ESCC

Qualified

ESCC QPL

See Spec

65ºC

59ºC

ESCC

Qualified

ESCC QPL

See Spec

-11ºC

-16ºC

ESCC

Qualified

ESCC QPL

See Spec

70ºC

61ºC

ESCC

Qualified

ESCC QPL

See Spec

116ºC

106ºC

ESCC

Qualified

ESCC QPL

See Spec

62ºC

53ºC

ESCC

Qualified

ESCC QPL

See Spec

13ºC

4ºC

ESCC

Qualified

ESCC QPL

See Spec

-13ºC

-18ºC

ESCC

Qualified

ESCC QPL

See Spec

91ºC

85ºC

ESCC

Qualified

ESCC QPL

See Spec