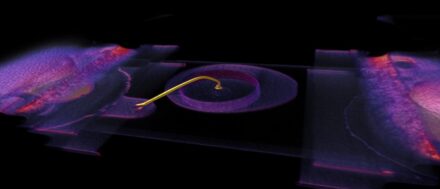

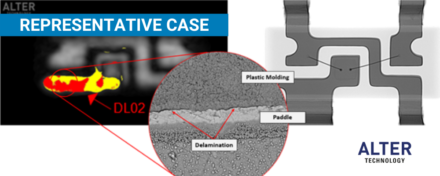

Cross Sectioning for SRAM Memory

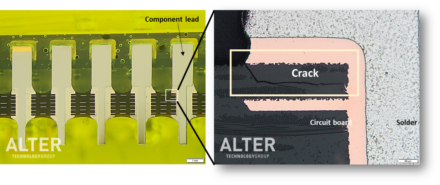

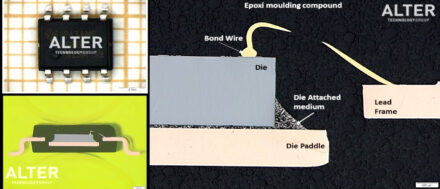

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

Cross Sectioning for SRAM Memory

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

6088 results found for SRAM/RAM/Memory/Digital/Microcircuits

Part reference

Quality level / QPL

Package

TID (krads)

SEE (MeV/mg/cm2)

Access Time [Max]

Memory Size

Unit price

Lead time

COMMERCIAL

Not qualified

NOT LISTED IN QPL

SILVER

Surface Mount

SOJ-32

12ns

1M (128K x 8)

883

Qualified

QPDSIS-38535

Through Hole Mount

CDIP-28

100 ns

256K (32K x 8)

QML Q

Qualified

QPDSIS-38535

Surface Mount

CQLCC-28

20 ns

64K (8K x 8)

QML H

Qualified

QPDSIS-38534

Surface Mount

CQFP-68 (Gull Wing)

70 ns

4M (128K x 32)

QML Q

Qualified

QPDSIS-38535

Through Hole Mount

CDIP-24

45 ns

16K (2K x 8)

883

Qualified

QPDSIS-38535

Surface Mount

CFP-28

15 ns

256K (32K x 8)

QML Q

Not qualified

QPDSIS-38535

Surface Mount

CQFP-68

55 ns

32K (2K x 16)

QML Q

Qualified

QPDSIS-38535

Through Hole Mount

CDIP-20

25 ns

16K (4K x 4)

QML H

Qualified

QPDSIS-38534

Surface Mount

CQFP-68 (Gull Wing)

100 ns

4M (128K x 32)

QML H

Qualified

QPDSIS-38534

Through Hole Mount

CDIP-32

45 ns

4M (512K x 8)

Part validation activities

Cost & Activity Matrix