Cross Sectioning for Fuses

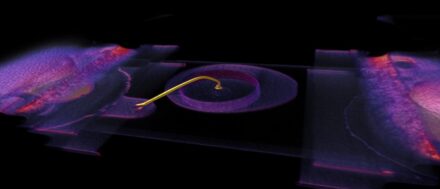

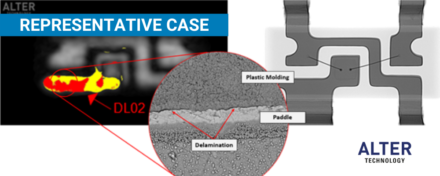

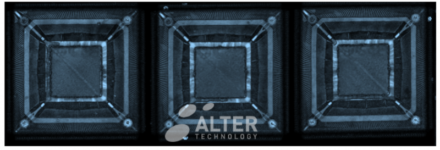

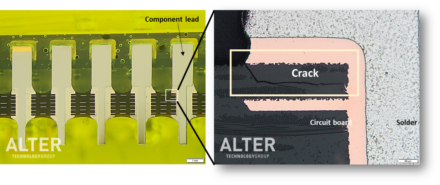

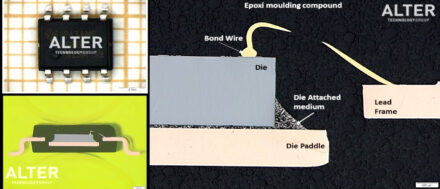

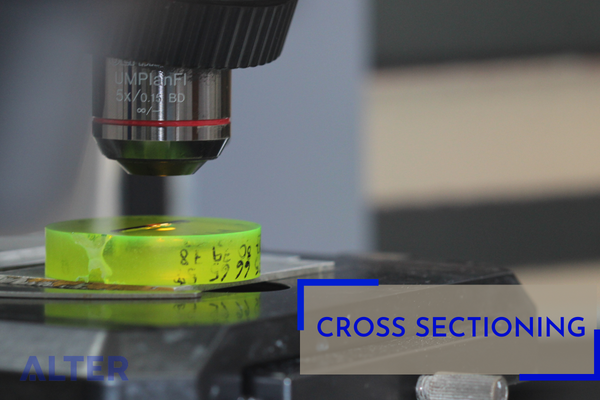

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

Cross Sectioning for Fuses

The cross-sectioning process provides access to the device internal structure, its materials and design. Electronics components are often subjected to cross-sectioning to detect the defects that could not be found using other testing techniques. Cross-sectioning typically involves three discrete steps: mounting the sample in a block of epoxy resin to form the specimen, grinding or cutting the specimen and finally polishing the exposed surface. >> Read more

EEE Parts Results Page

1280 results found for Fuses/Fuses and Fuseholders

Part reference

Quality level / QPL

Package

Breaking Capacity

DC Rated Voltage

Rated Current

Response Time

Unit price

Lead time

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

6x31mm

10kA

Normal Blow

MILITARY STD.

Not qualified

QPDSIS-15160

Cartridge

Cartridge

10x38mm

35A

Time delay (Slow Blow)

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge blade

47x104mm

150kA DC, 200kA AC

Normal Blow

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

14x51mm

10kA

Normal Blow

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

10x38mm

150kA DC, 200kA AC

Normal Blow

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge blade

47x104mm

150kA DC, 200kA AC

Normal Blow

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

10x38mm

35A

Time delay (Slow Blow)

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

10x38mm

35A

Normal Blow

MILITARY STD.

Not qualified

QPDSIS-15160

Cartridge

Cartridge

20x76mm

10kA DC, 200kAC

Time delay (Slow Blow)

MILITARY STD.

Qualified

QPDSIS-15160

Cartridge

Cartridge

10x38mm