Package crack/void between non-connected terminals is a critical anomaly in plastic encapsulated parts. This is so as these can turn into a conductive path and lead to catastrophic failures. In this regard, Scanning Acoustic Microscopy (SAM) is the most effective non-destructive approach for the sensitive detection of such deviations within plastic packages. The present note shows the comprehensive inspection of a thick power transistor and the detection of this type of internal anomalies.

Sample & Method

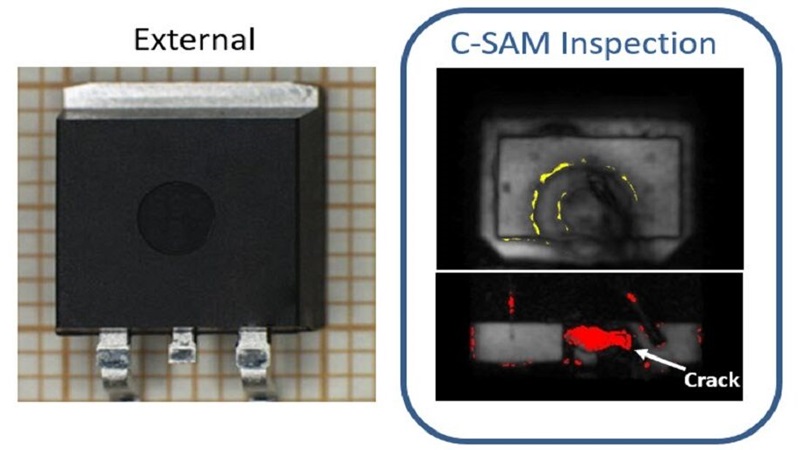

The images show the confocal scanning acoustic microscopy (C-SAM) inspection of a power transistor specially designed for hard switching SMPS topologies. Similarly to other power transistors, the device features a thick plastic package (TO-263). Thus an appropriate transducer/frequency must be specifically selected for the comprehensive inspection of the systems and to reach the required quality and definition.

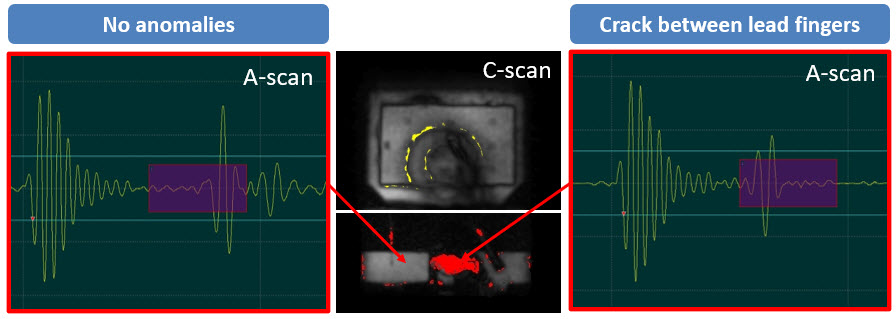

In such a thick package a multi-depth inspection approach is selected to confocally resolve micrometric cracks thanks to the C-Scan-mode of the acoustic microscope. This inspection process is conducted i.a.w. the acceptance/rejection criteria indicated in the applicable inspection methods (J-STD-020E, ESCC 25200, PEM-INST-001 & MIL-STD-1580).

Remarks

C-mode scanning acoustic microscopy discloses a rejectable crack that extends the whole length between at least two terminals. In this case, the image was optimized to register the crack.

The A-scan below shows clear phase inversion sings (right) that contrast with the normal-positive peak detected on a defect-free lead finger (left). Such a type of anomaly is considered a cause of rejection according to different test methods. This is so as the detected crack can open a conductive path between lead-frame-fingers designed to be isolated, which compromises the reliability and the suitable performance of the device.

Antonio José Rey

Antonio is a specialist in the inspection of high-reliability EEE components, with extensive experience using advanced microscopy techniques such as SEM and SAM. He began his career in the aerospace sector in 2014 as a Quality Technician in the Incoming-Inspection Service, where he developed expertise in radiographic inspection, lead material verification, and other testing methods. Since 2017, Antonio has been part of the Destructive Physical Analysis Laboratory, conducting detailed physical tests using tools like Confocal Scanning Acoustic Microscopy.