A product assurance plan defines quality, reliability, and component requirements to ensure mission success in New Space projects.

Blog » EEE Testing »

A product assurance plan defines quality, reliability, and component requirements to ensure mission success in New Space projects.

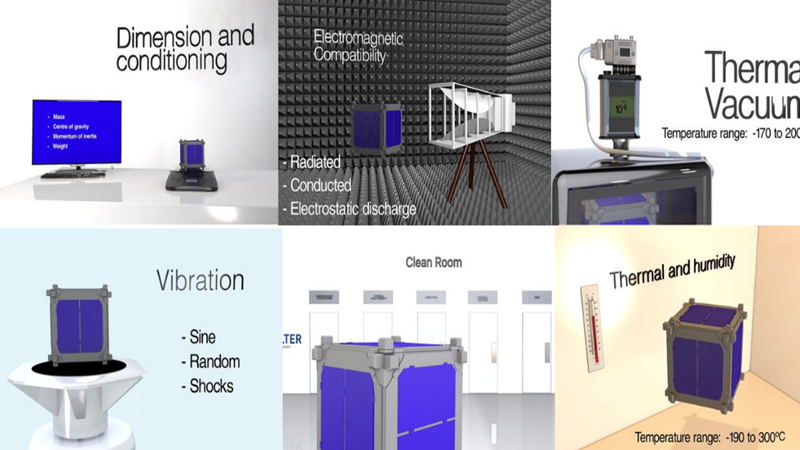

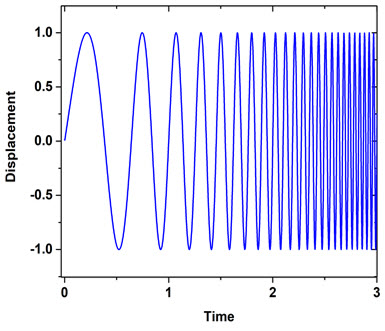

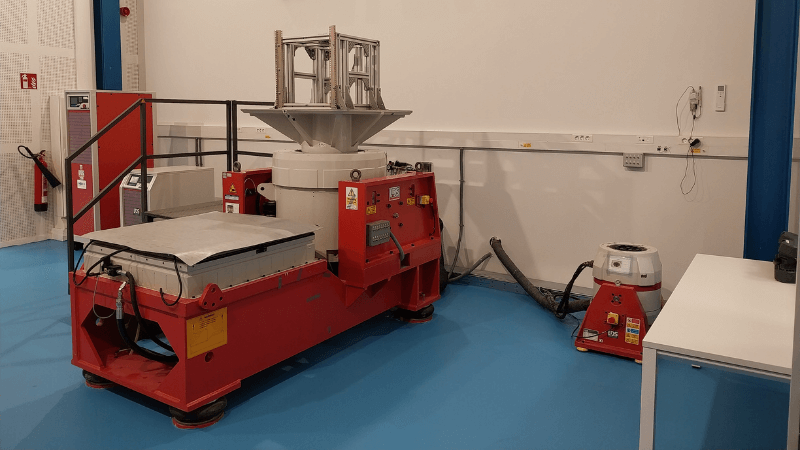

Vibration testing for small sats simulates launch conditions to ensure structural integrity and reliability in space.

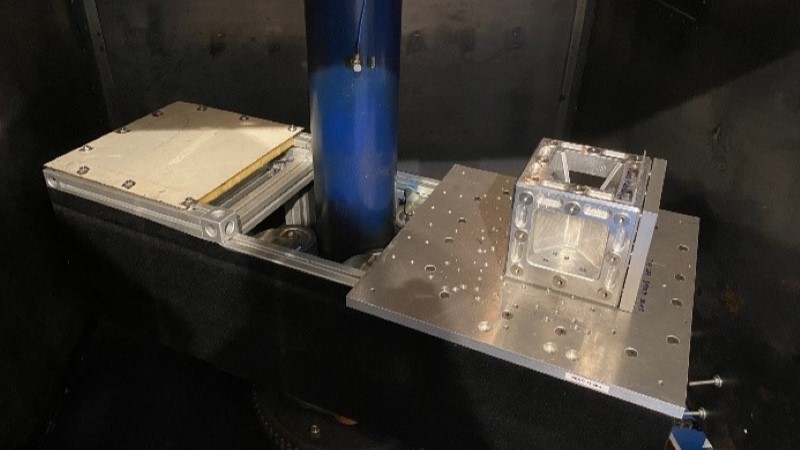

TID irradiation testing evaluates radiation effects on small satellites to ensure reliability under space conditions.

SRS shock testing simulates the sudden impact during satellite deployment, ensuring structural integrity and performance under launch conditions.

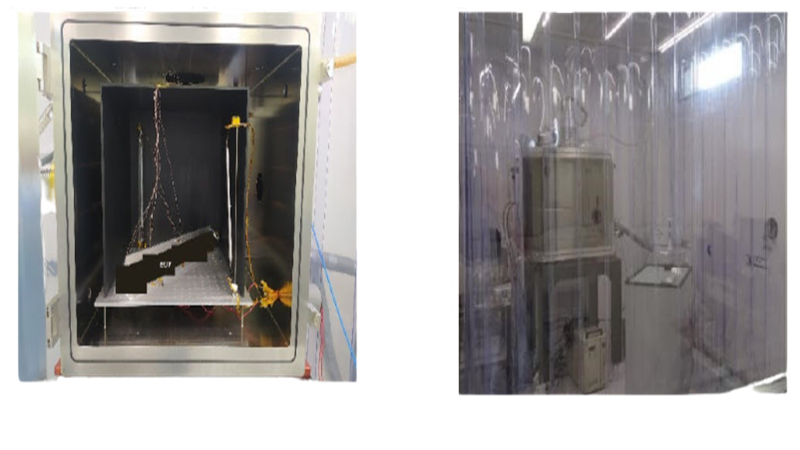

TVAC testing simulates the thermal and vacuum conditions of Low Earth Orbit to ensure smallsat durability and performance in space.

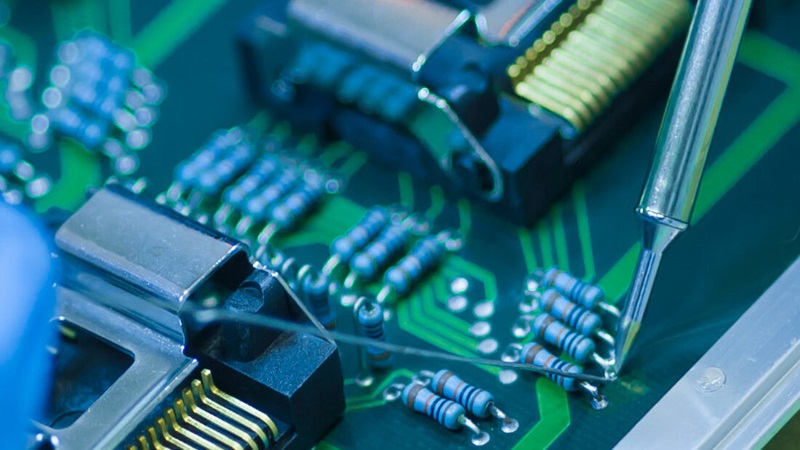

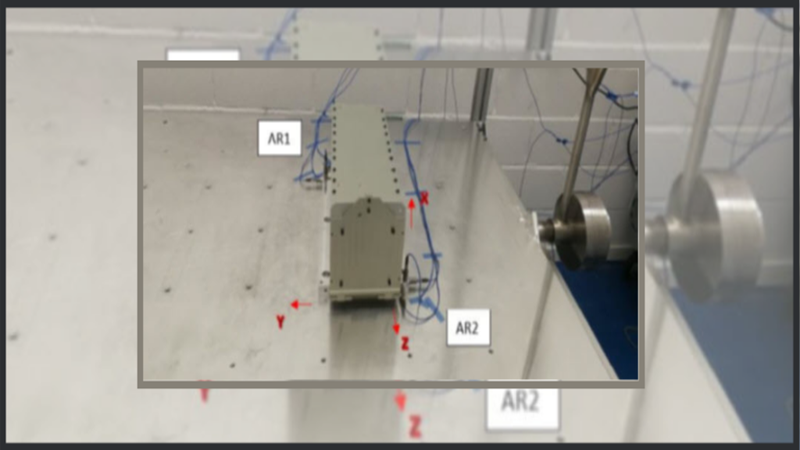

EMI/EMC testing ensures electromagnetic compatibility by assessing emissions and immunity to prevent interference in space systems.

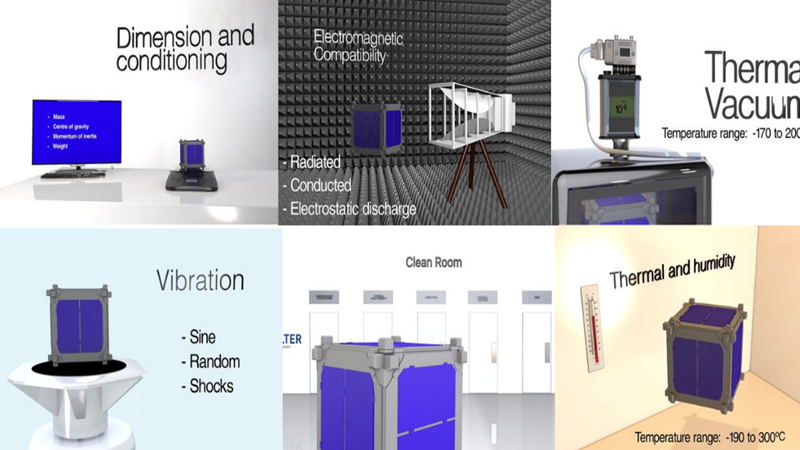

Small satellites equipment testing ensures reliability through EMI/EMC, thermal vacuum, vibration, and shock tests for space readiness.

Acceleration tests assess equipment reliability under fixed acceleration stress, simulating conditions in aircraft and missiles.

Static magnetic field tests ensure accurate calibration of space equipment by generating uniform, adjustable magnetic fields.