A detail specification defines mechanical, electrical, and testing requirements for components, ensuring compliance with project standards.

Blog > EEE Testing >

A detail specification defines mechanical, electrical, and testing requirements for components, ensuring compliance with project standards.

EEPROM devices in space missions are vulnerable to radiation effects like TID and SEE, impacting data integrity and system reliability.

Red Plague is a corrosion issue in silver-plated copper conductors, affecting reliability in space applications.

Alert and obsolescence management ensures early detection of EEE part issues, preventing disruptions in space projects.

Platinum temperature sensors offer accuracy and stability in space applications, with assembly options like crimping, laser welding, and soldering.

Electrostatic discharges testing assesses EUT resilience to contact and air discharges, ensuring reliable operation under electrical stress.

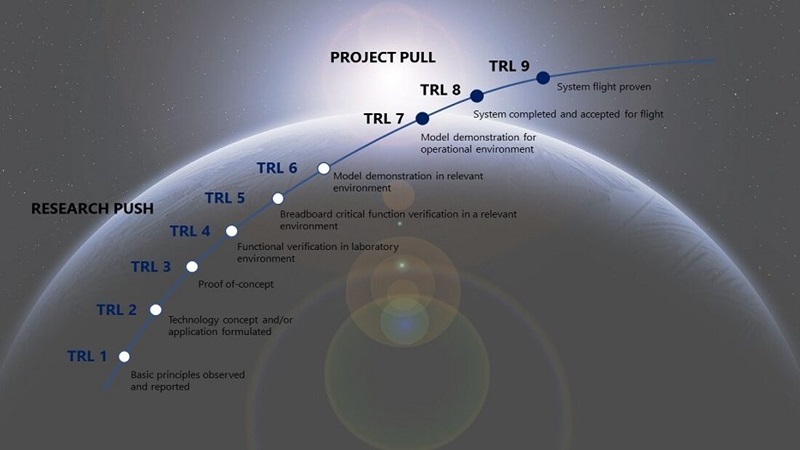

During the last decades, continuous technology improvement has allowed the development of increasingly smaller and cheaper satellites. Different...

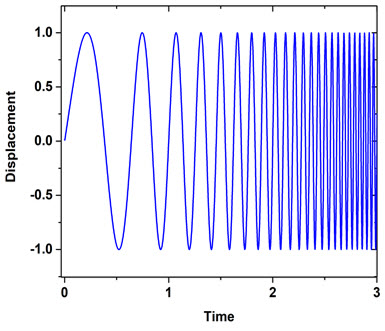

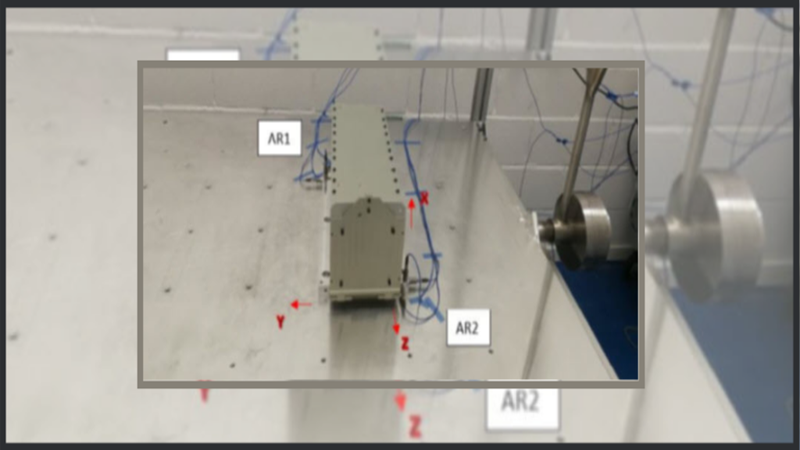

Vibration testing for small sats simulates launch conditions to ensure structural integrity and reliability in space.

TID irradiation testing evaluates radiation effects on small satellites to ensure reliability under space conditions.

SRS shock testing simulates the sudden impact during satellite deployment, ensuring structural integrity and performance under launch conditions.

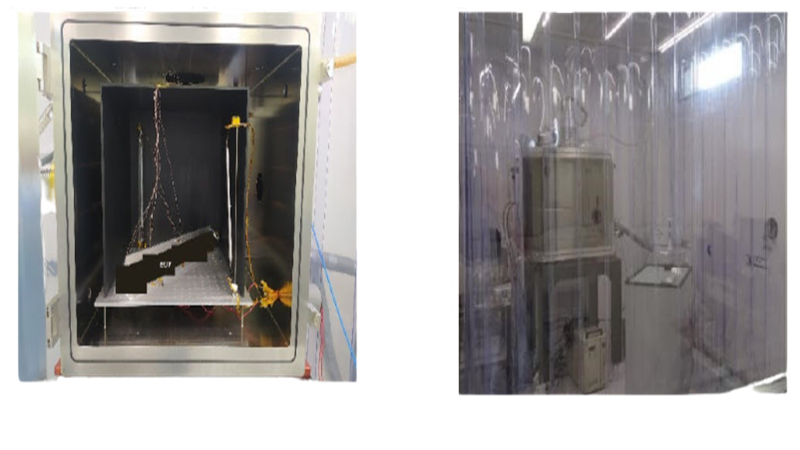

TVAC testing simulates the thermal and vacuum conditions of Low Earth Orbit to ensure smallsat durability and performance in space.

EMI/EMC testing ensures electromagnetic compatibility by assessing emissions and immunity to prevent interference in space systems.

Small satellites equipment testing ensures reliability through EMI/EMC, thermal vacuum, vibration, and shock tests for space readiness.

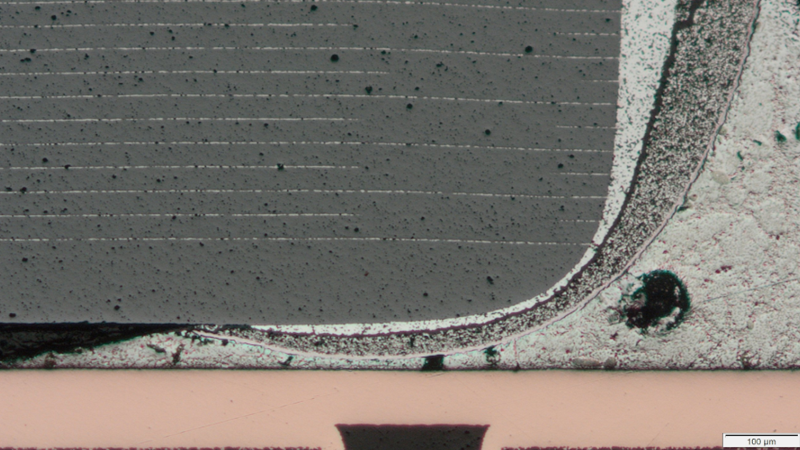

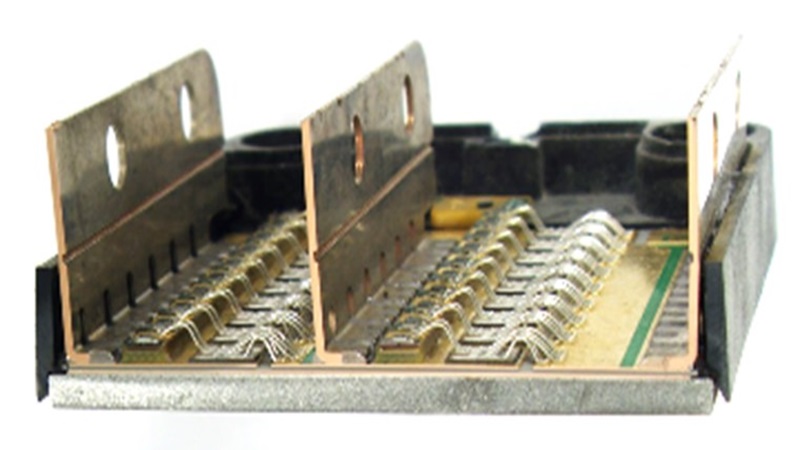

DPA parts examination verifies EEE component quality through detailed inspections, detecting defects that could impact system reliability.

Testing COTS ensures reliability for space applications through assessment, screening, and qualification to mitigate potential risks.

Testing SiC Schottky diodes under heavy ion radiation evaluates performance, reverse bias limits, and module configurations.

Automotive SiC module technology enables higher efficiency in EV inverters, supporting advanced power density and thermal performance.

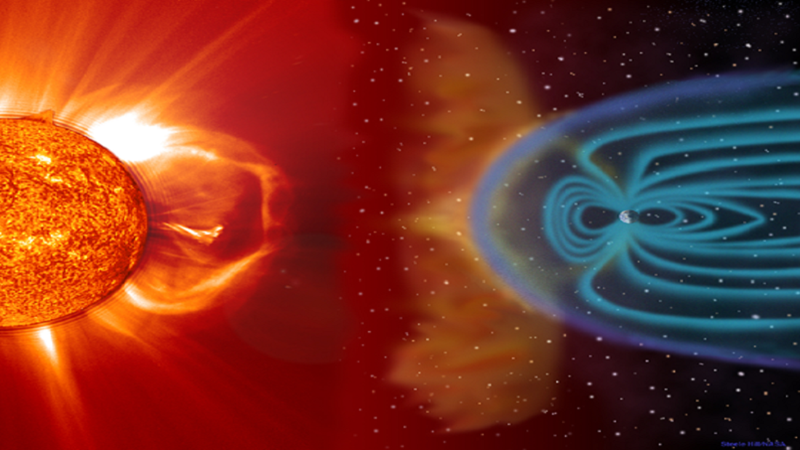

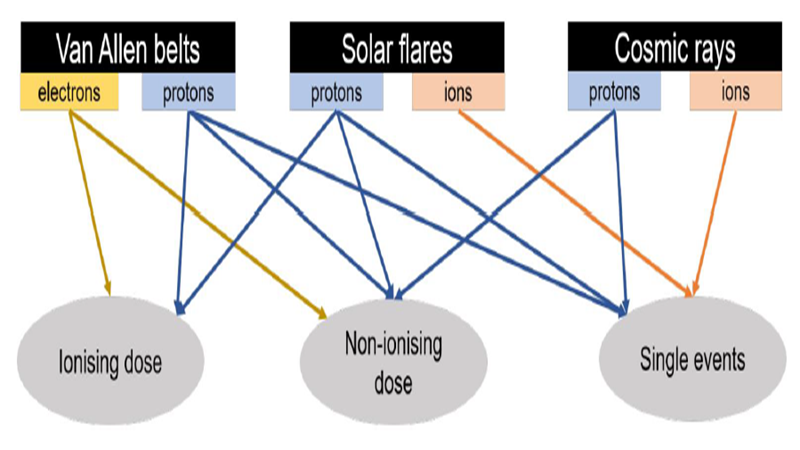

Space radiation affects spacecraft electronics, causing degradation and failures. Testing and modeling help predict and mitigate these effects.

GaN power HEMTs exhibit unique behavior under short-circuit conditions, impacting performance and reliability.

Optical transceiver technology enables high-speed data transmission in space vehicles, ensuring reliable communication systems.