Explore expert answers on non-destructive inspection techniques for plastic COTS parts using SAM in this Q&A recap.

Blog » EEE Testing »

Explore expert answers on non-destructive inspection techniques for plastic COTS parts using SAM in this Q&A recap.

Non-destructive inspection using acoustic microscopy enhances reliability screening of plastic COTS and electronic systems.

Failure analysis insights with real case studies and testing methods for identifying failure modes in aerospace components.

Radiation environment analysis for space systems, including TID, TNID, and SEE evaluation on satellite components.

Explore expert answers on space radiation effects, simulation tools, and COTS testing from our recent technical webinar.

Get expert answers to key questions on CSAM inspections, water use, delamination, and EEE package reliability.

This webinar provides a brief overview of Scanning Acoustic Microscopy and the non-destructive inspection of EEE parts.

Degolding removes gold plating to prevent brittle solder joints, but NiPdAu finishes are exempt as they pose no embrittlement risk.

VPG foil resistors offer high precision and low TCR, with testing options based on DSCC drawings or EEE-INST-002 standards for space use.

Operational Amplifiers (OpAmp) for space applications must meet strict requirements for temperature, radiation tolerance, and material compliance.

Degolding and retinning can affect coplanarity in leadless SMD packages, impacting electrical performance in space applications.

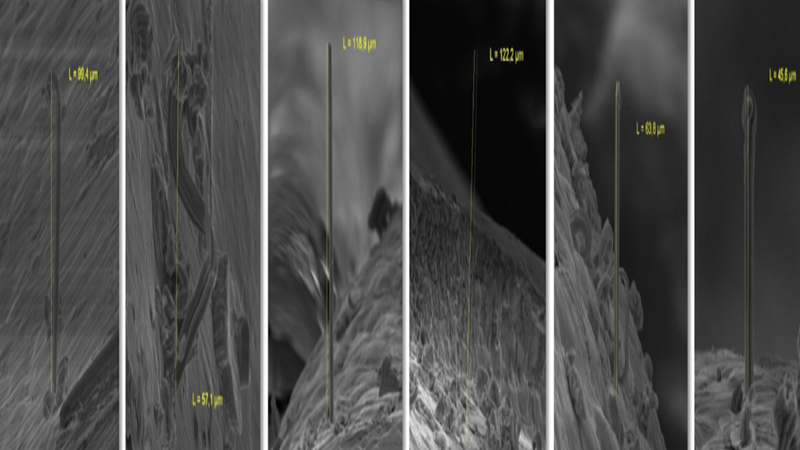

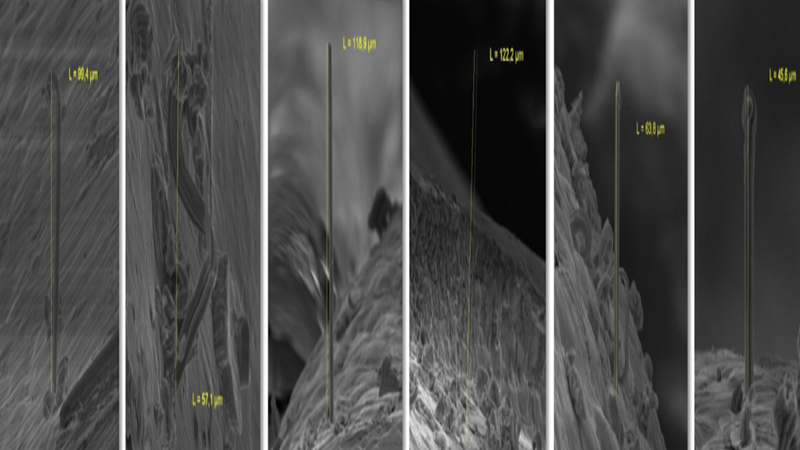

Tin whisker growth can be delayed but not fully prevented, highlighting the need for strict material controls in high-reliability applications.

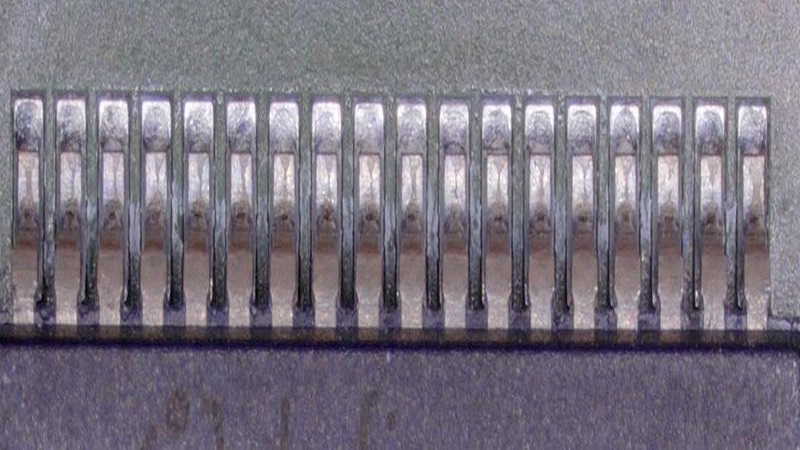

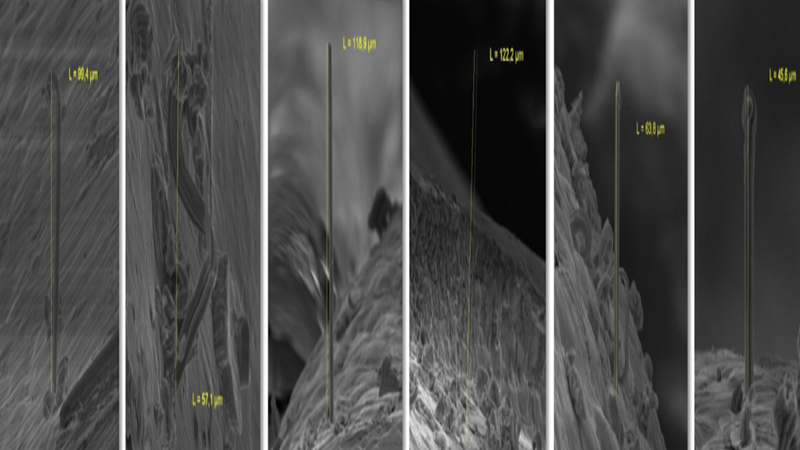

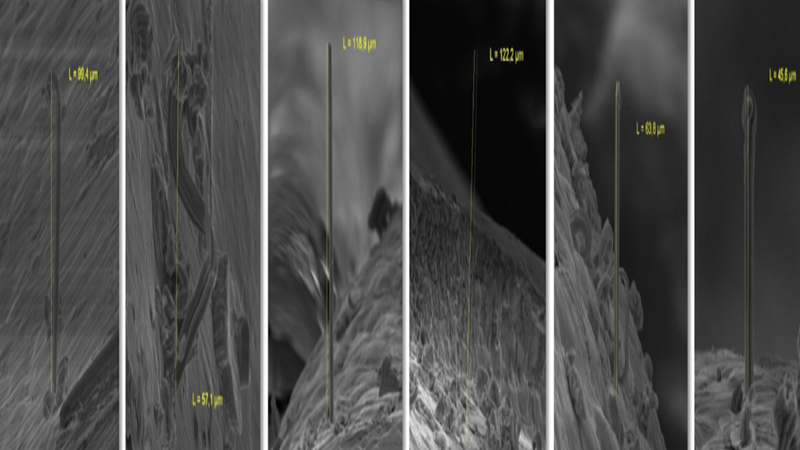

Tin whisker growth was detected after prolonged high-temperature and humidity storage, with lengths reaching up to 192μm in some samples.

Tin whisker formation was tested under various conditions, with growth detected after high-temperature and humidity storage cycles.

Tin whisker growth is an unpredictable phenomenon that can cause failures in high-reliability applications, including space systems.

Parts selection is crucial in Space applications, balancing performance, availability, quality, and lead time to ensure design feasibility.

Product Assurance Support ensures compliance with reliability, safety, and quality standards in space missions, minimizing failure risks.

Parts Procurement Control Parts (PPCP) ensures EEE components meet quality, reliability, and procurement standards in space projects.

The main challenge for EEE parts performing on Space projects is to withstand the extreme and harsh environment they must work in. This involves...

A detail specification defines requirements for procuring parts, ensuring compliance with mechanical, electrical, and testing standards.