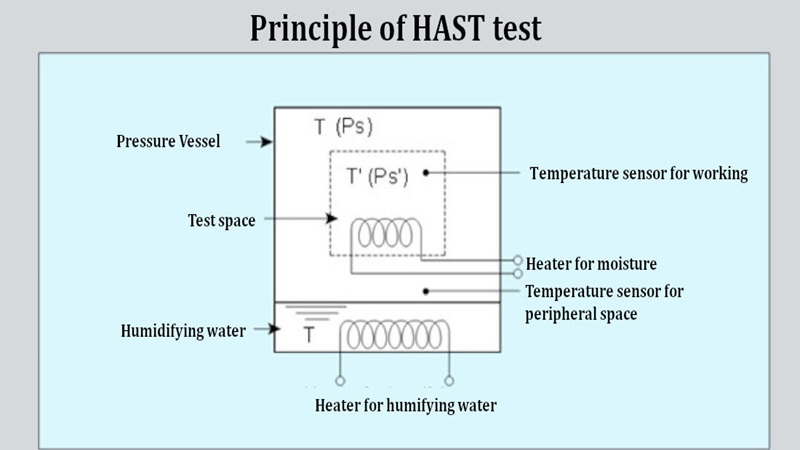

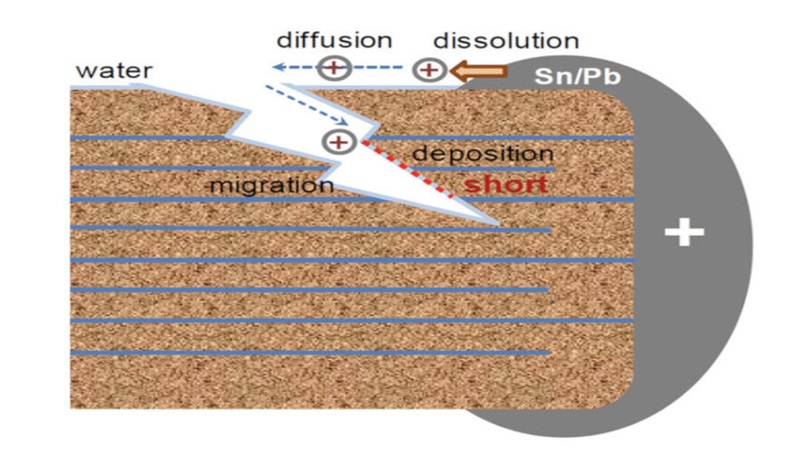

HAST test accelerates humidity reliability checks for electronics, reducing test time while ensuring accurate, representative results.

Blog » EEE Testing »

HAST test accelerates humidity reliability checks for electronics, reducing test time while ensuring accurate, representative results.

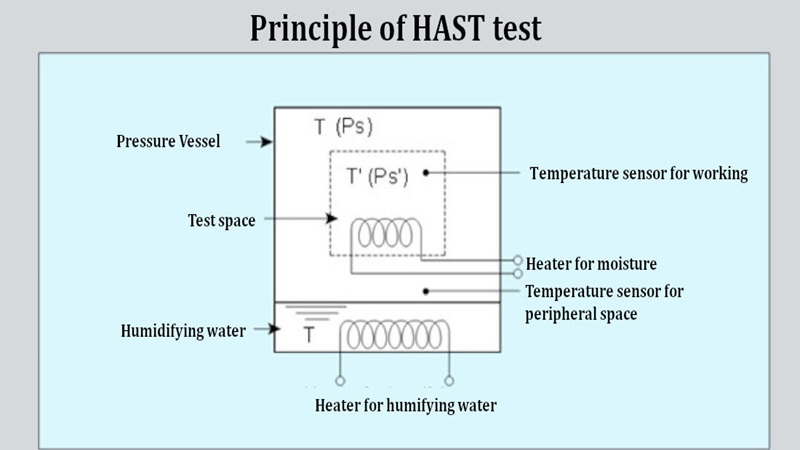

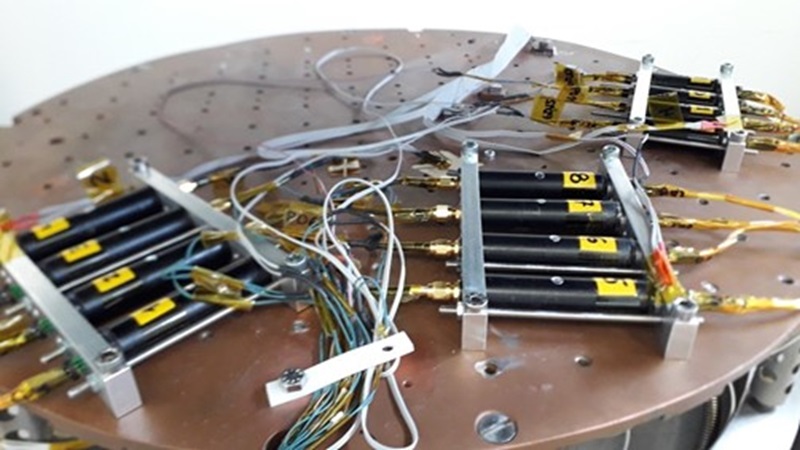

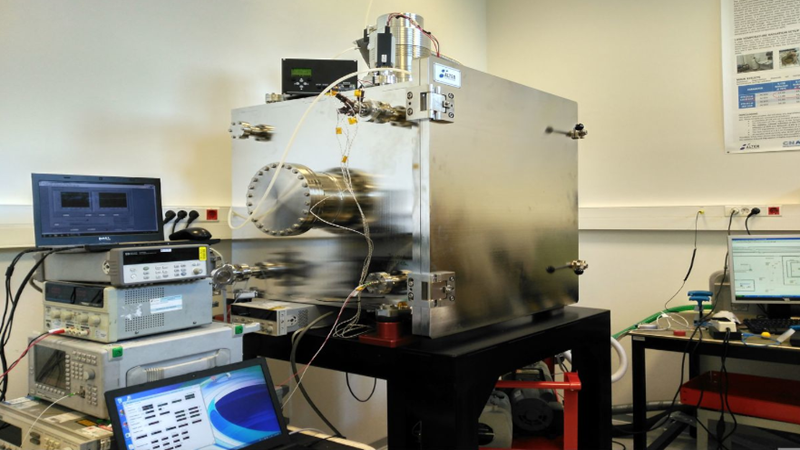

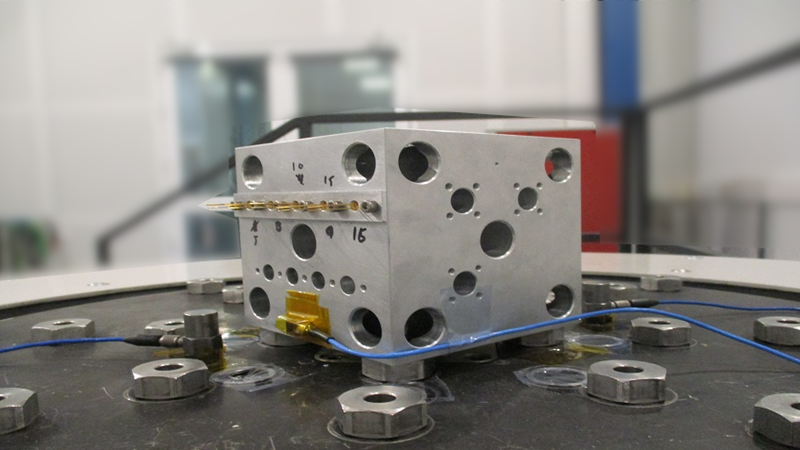

Angular sensors tested for space: modular benches enable precise qualification under extreme temperature and vacuum conditions.

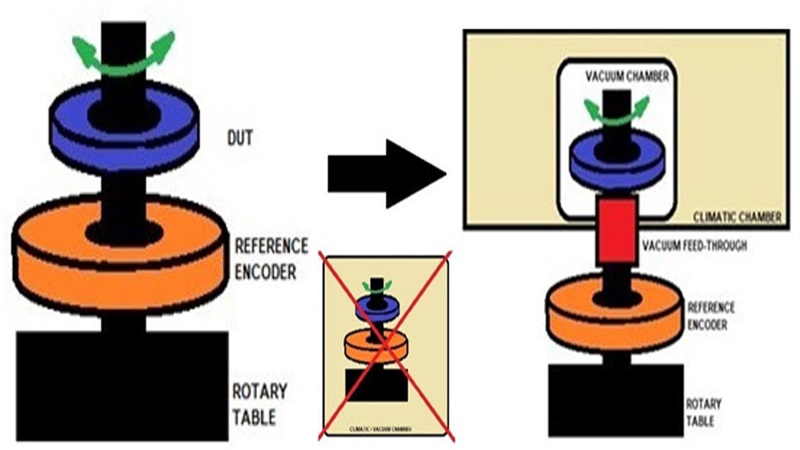

Mars 2020 SuperCam calibration target—key for Mars rover imaging, mineral ID, and instrument health checks.

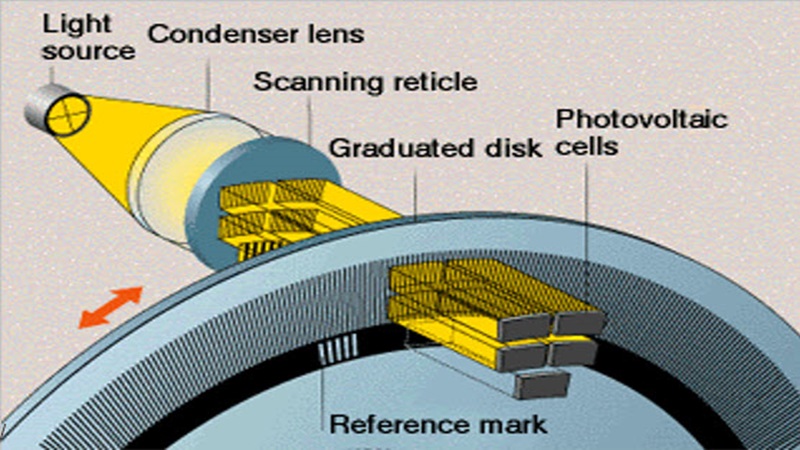

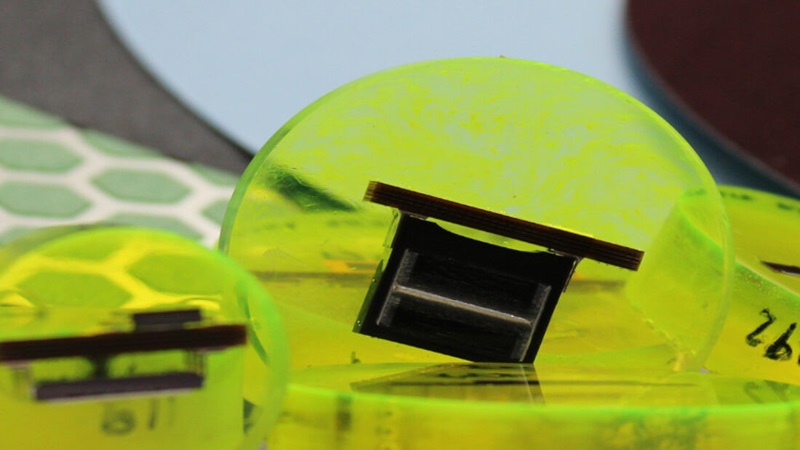

Angular sensors enable precise position control in space mechanisms, with performance varying by technology and application.

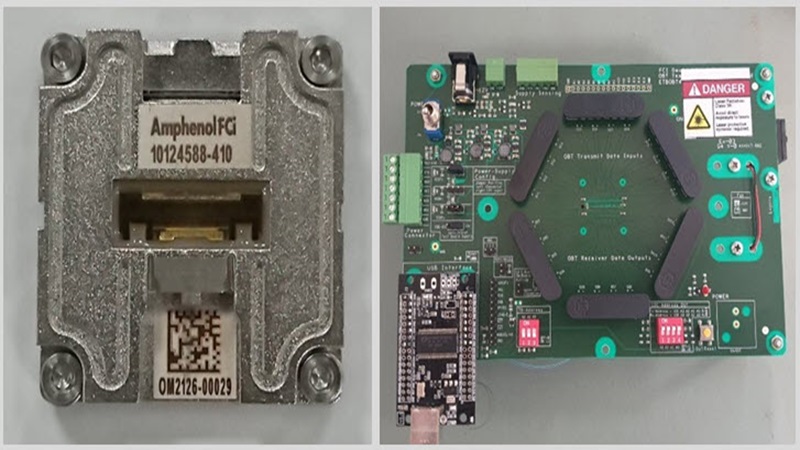

Electro-optical characterization of optical transceivers reveals signal integrity and BER at high-speed data rates.

Endurance testing of lasers in vacuum ensures stability, accurate control, and traceability across all wavelengths.

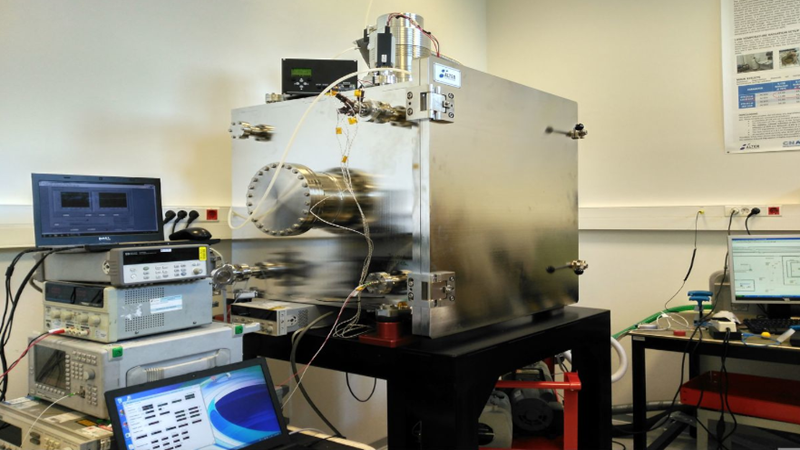

Thermal vacuum testing of IR sources under extreme temperatures ensures reliability and accurate characterization.

Thermal Vacuum Testing ensures space components withstand extreme cold, heat, and ultra-high vacuum environments.

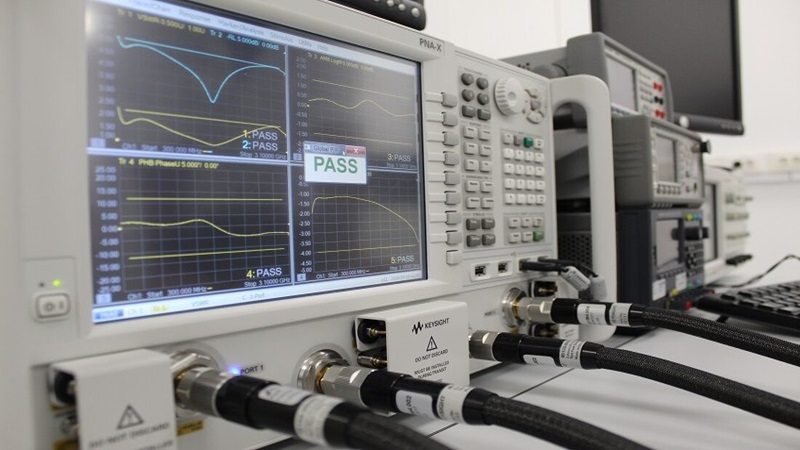

Microwave testing lab offering expert analysis, design, and inspection for high-reliability microwave systems.

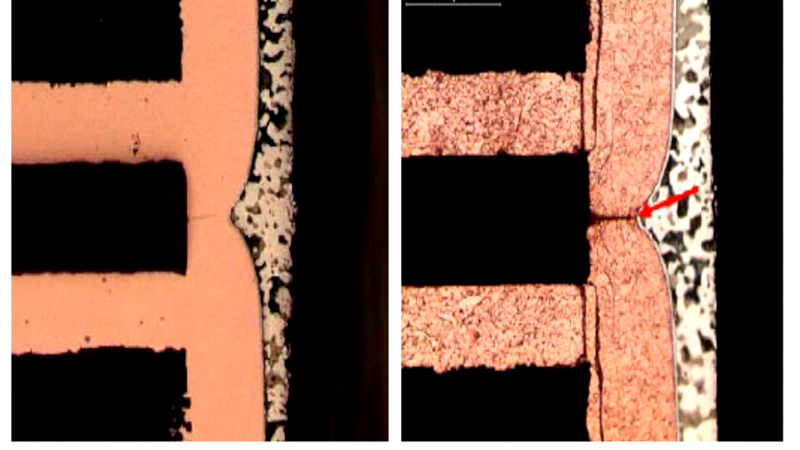

Fluorescence microscopy detects cracks and defects with high sensitivity, enhancing failure analysis in high-reliability electronics.

Microsectioning enables internal inspection of EEE parts, revealing structural defects in PCBs per ESA and industry qualification standards.

Plated Through Via (PTV) reliability depends on plating thickness, voids, and cracks; cross-section analysis ensures structural integrity.

MLCC reliability in space systems is challenged by cracking, often from soldering stress; design and screening help mitigate failures.

A DCL tracks all EEE components used in space systems, detailing specs, approvals, and changes for project validation and review.

A parts approval document defines test, quality, and radiation criteria to certify components for use in space or critical applications.

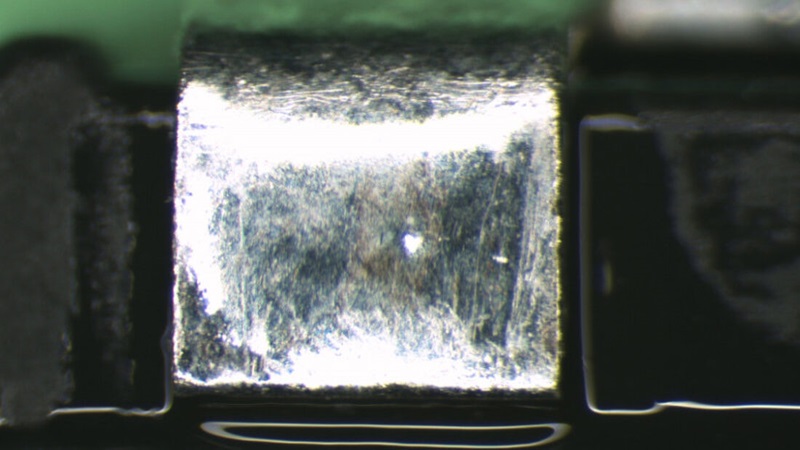

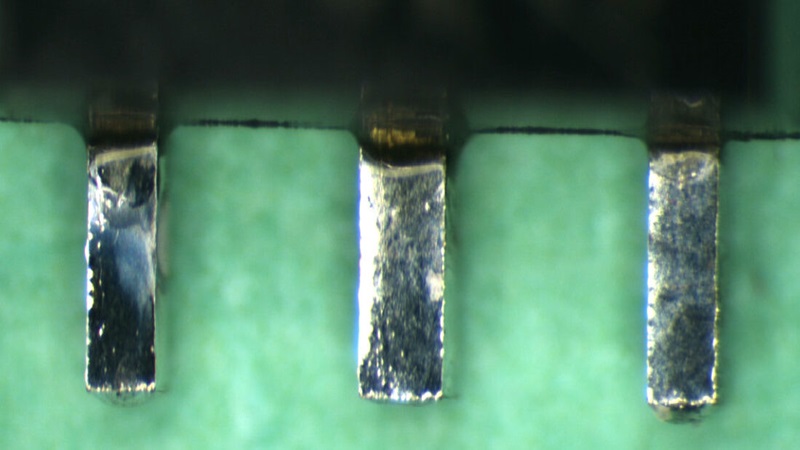

Solderability refers to how well a surface can be wetted by solder, assessed through visual or force-based test methods.

MIL-STD-883 defines solderability testing via Dip and Look to assess termination quality after steam aging and solder dipping.

Image sensors convert photons into electronic signals, with key parameters like responsivity, SNR, and dark current analyzed.

Lot Acceptance Test (LAT) verifies a component batch’s reliability through screening and endurance tests before final application use.

Acceptance Quality Limit (AQL) defines the maximum defect rate allowed in a batch based on statistical sampling.