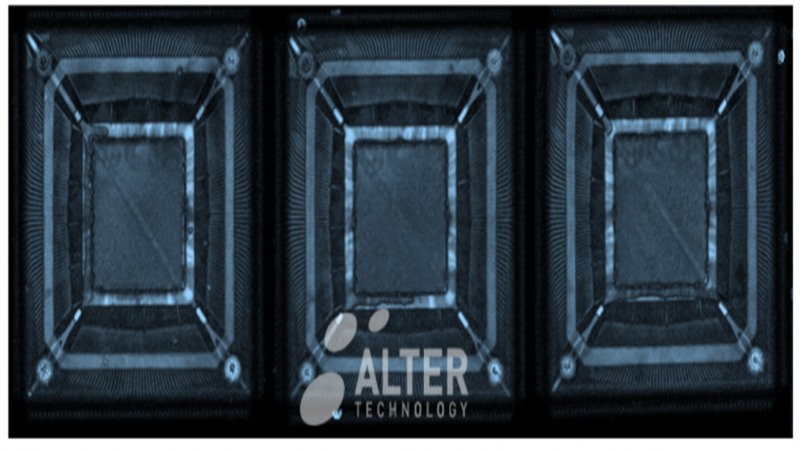

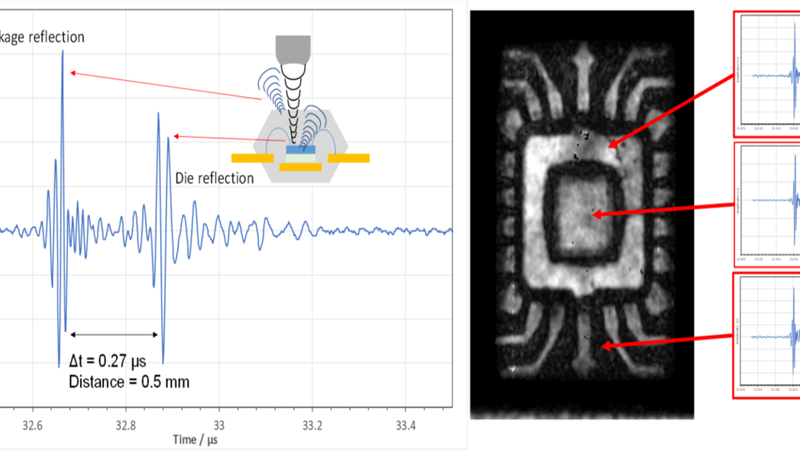

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

Blog » EEE Testing »

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

SAM enables non-destructive internal inspection of microelectronic parts by analyzing acoustic wave reflections and contrasts.

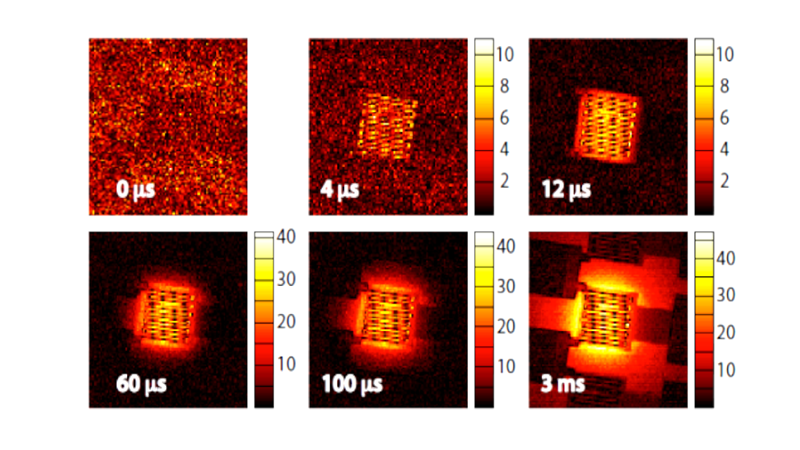

Thermoreflectance Thermal Imaging (TTI) maps micro-scale temperature gradients in devices with high spatial and temporal resolution.

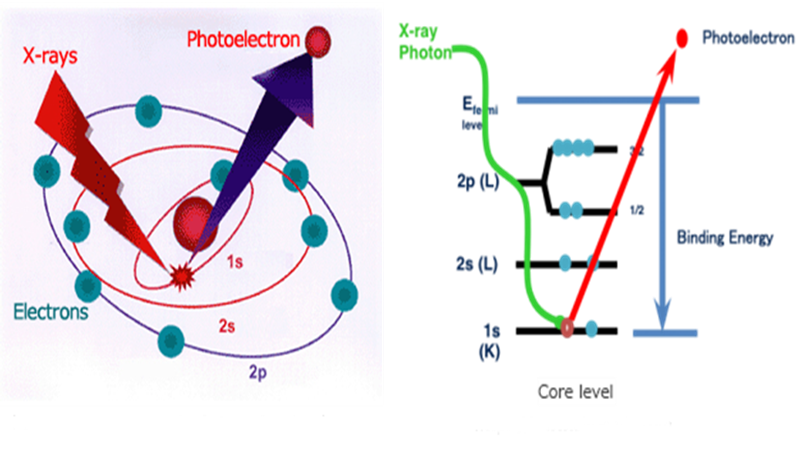

XPS provides precise, non-destructive surface analysis of thin films, revealing elemental composition at nanometer-scale depth.

Cross-sectioning reveals internal structures and defects in components through precise grinding and polishing.

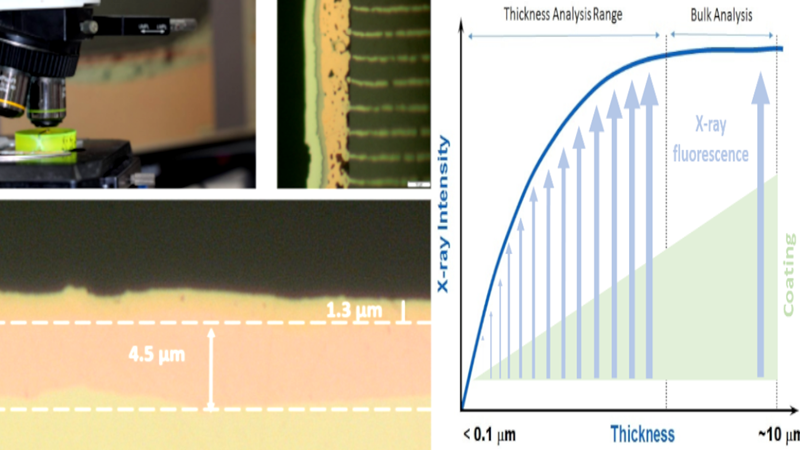

X-ray fluorescence enables non-destructive measurement of coating thickness with high precision and reliability.

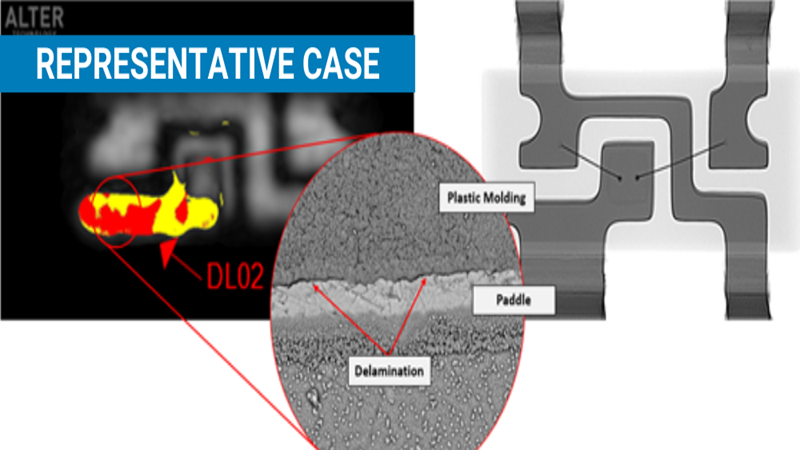

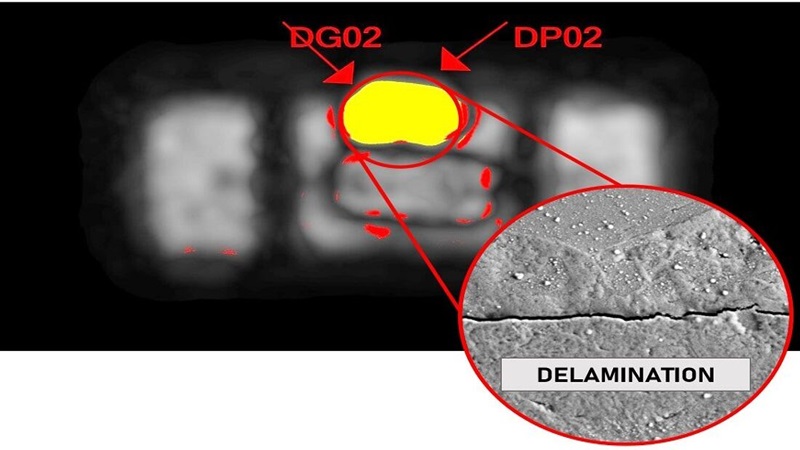

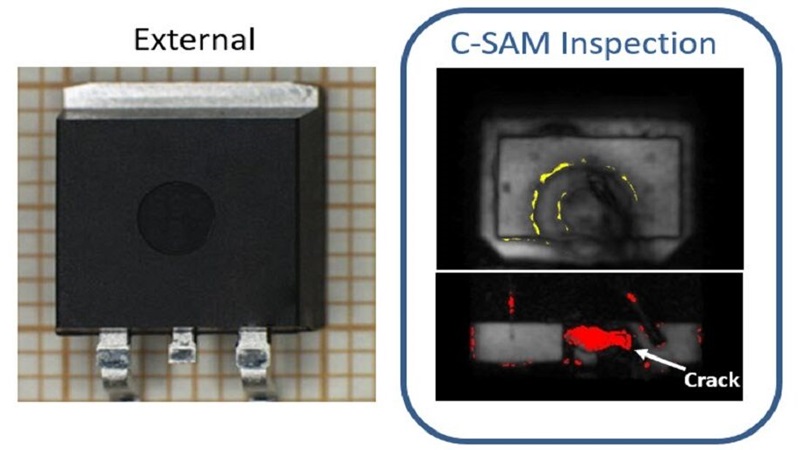

Delamination detection using acoustic microscopy reveals internal defects in plastic components, crucial for high-reliability applications.

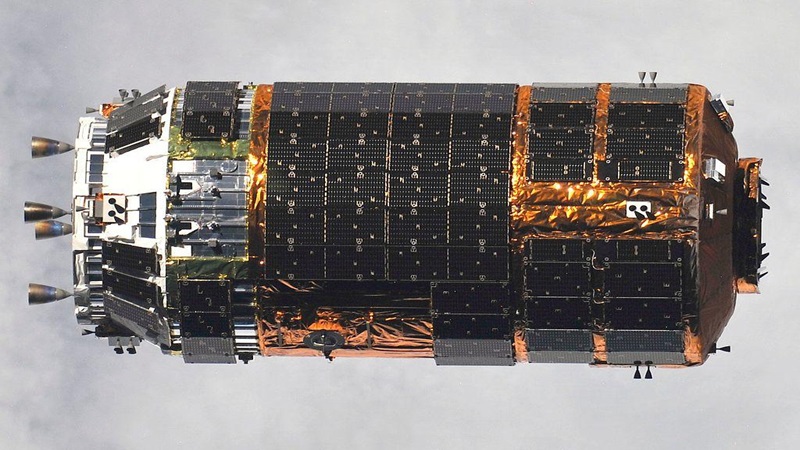

Space applications demand fault-free electronic components tested for extreme conditions to ensure long-term satellite reliability.

Humidity test evaluates component reliability by exposing devices to moisture and heat to reveal potential failures or degradation.

Delaminations in COTS components can lead to mechanical and electrical failures, making inspection essential for space use.

Leakage pathway detection uses dye tests to reveal cracks or voids compromising device reliability and sealing.

External visual inspection checks EEE parts for defects or damage using optical tools, ensuring compliance with standards.

Non-mechanical optical switches show strong potential for space use, with B-EO and MO technologies performing reliably.

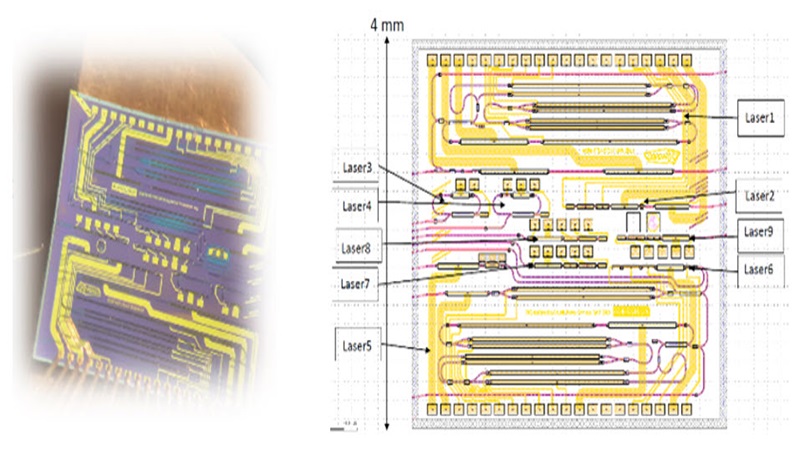

Photonic integrated circuits offer radiation-resistant solutions for data, sensing, and space-based communication systems.

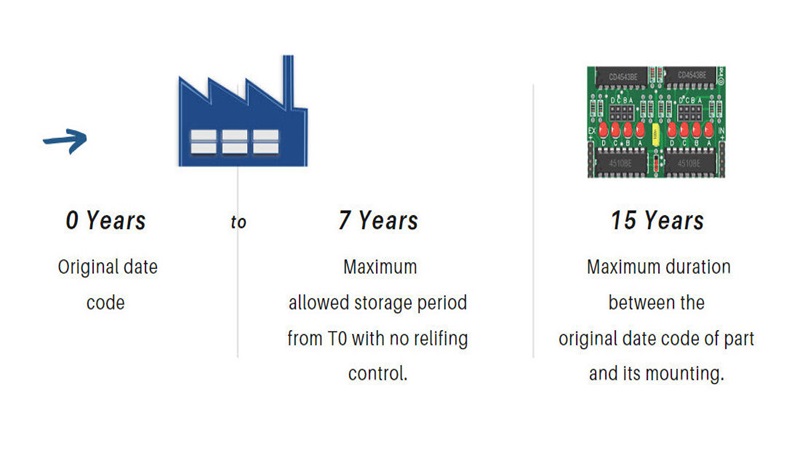

Long term storage of EEE components requires strict controls on environment, handling, and packaging to avoid degradation.

ECSS-Q-ST-60-14C outlines relifing rules for stored EEE parts, ensuring their suitability for space applications over time.

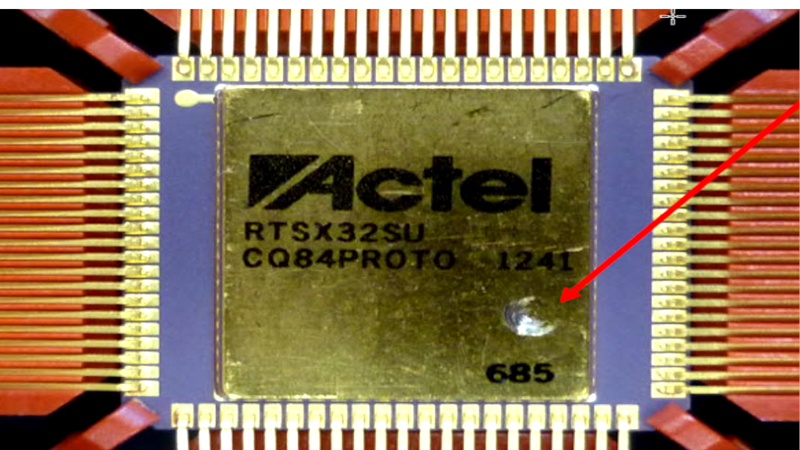

External visual inspection ensures EEE parts quality by identifying critical features and common issues in FPGAs and components per MIL-STD-883 Method 2009.

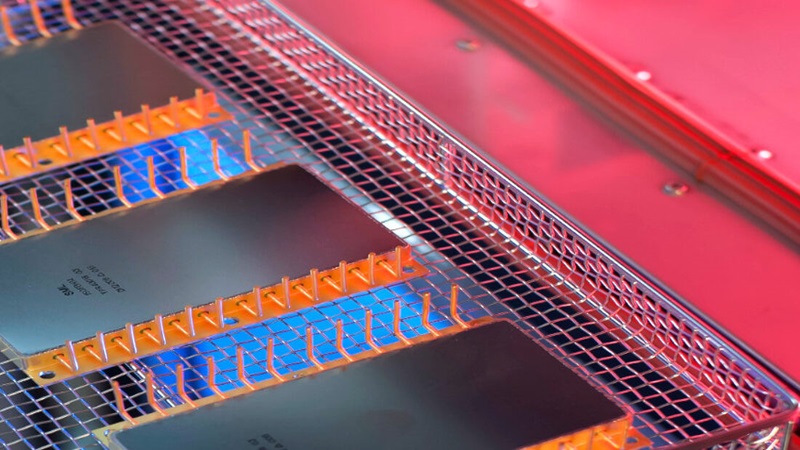

Scanning Acoustic Microscopy enables reliable crack detection in plastic packages, preventing failures in electronic components.

Incoming inspection ensures part quality by checking materials for non-conformance before inventory or production use.

Burn-in test screens electronics for early failures, removing defective parts to ensure long-term reliability and product quality.