Overview of mechanical stress methods for lead integrity test in electronic parts, based on MIL-STD-883 and advanced force/fatigue tools.

Blog » EEE Testing »

Overview of mechanical stress methods for lead integrity test in electronic parts, based on MIL-STD-883 and advanced force/fatigue tools.

Life test applies electrical stress to reveal wear-out failures and assess long-term device reliability performance.

New space microelectronics benefit from SAM’s non-destructive defect imaging in complex, high-reliability components.

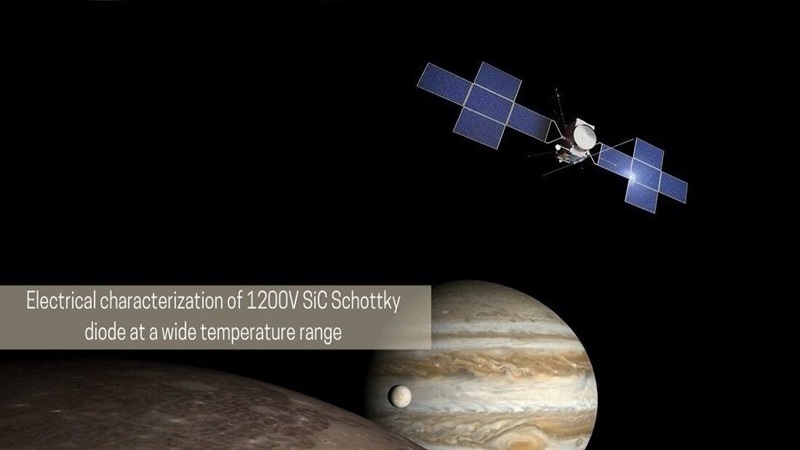

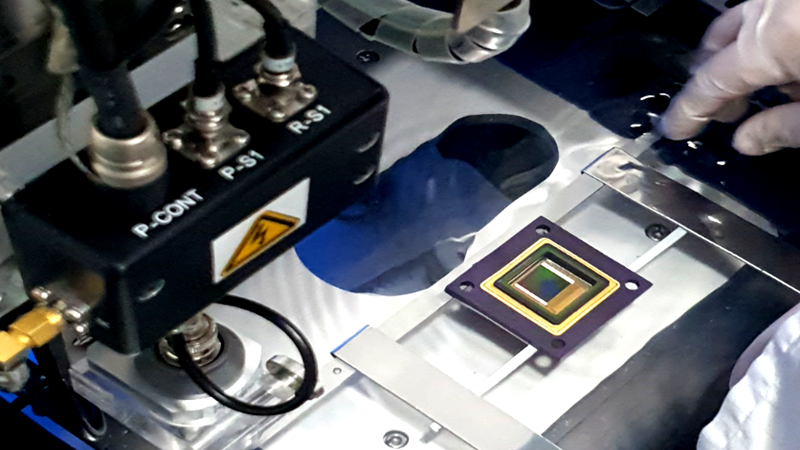

Electrical characterization of SiC diodes shows reliable performance under high temperatures and varying voltage conditions.

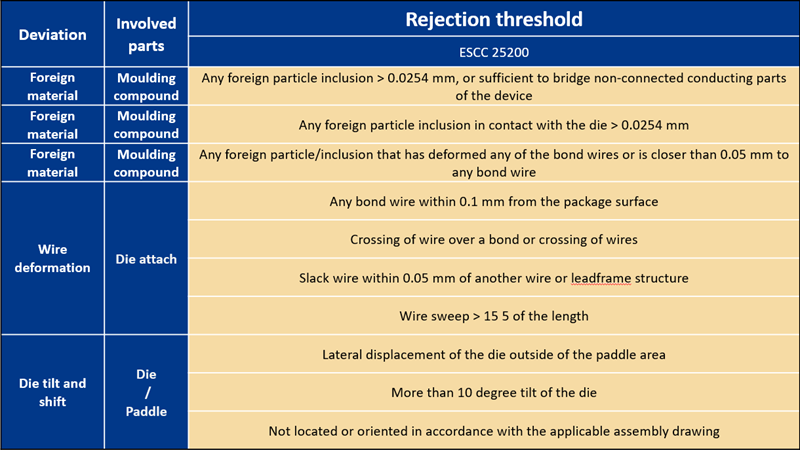

Comparison of SAM rejection criteria across IPC, ESCC, MIL-STD, and NASA specs for cracks, voids, delamination, and contamination.

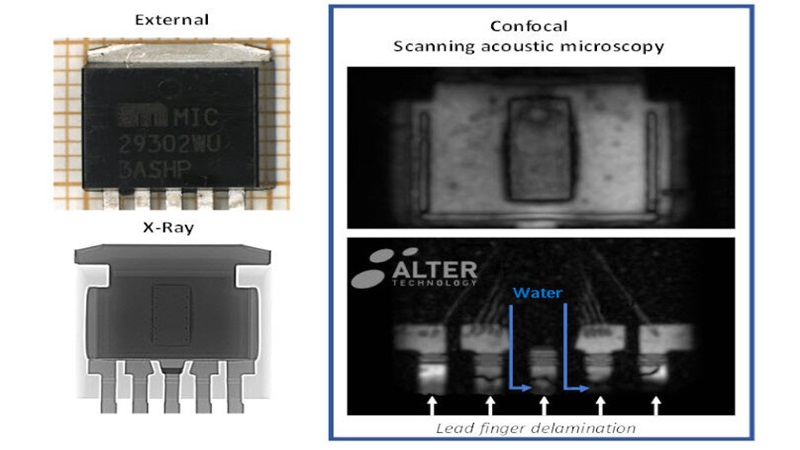

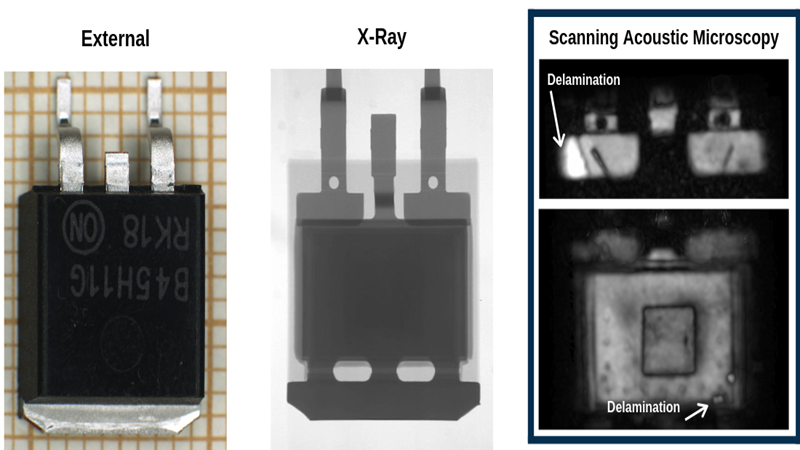

Scanning acoustic microscopy (SAM) detects water ingress paths and hidden flaws in delaminated parts of microelectronic systems.

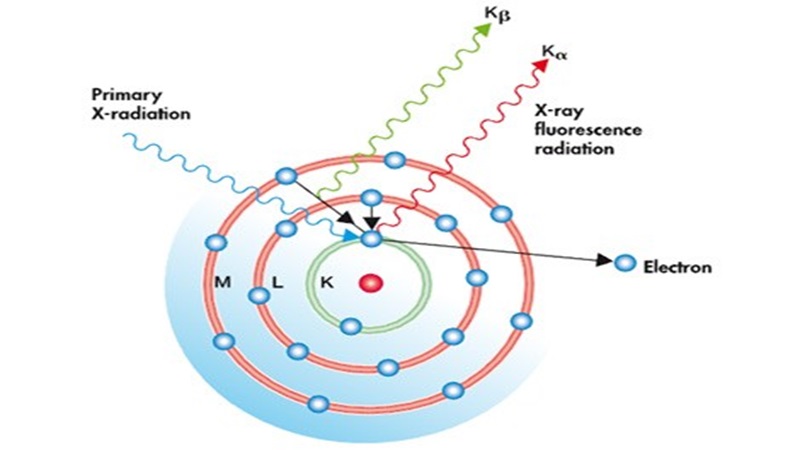

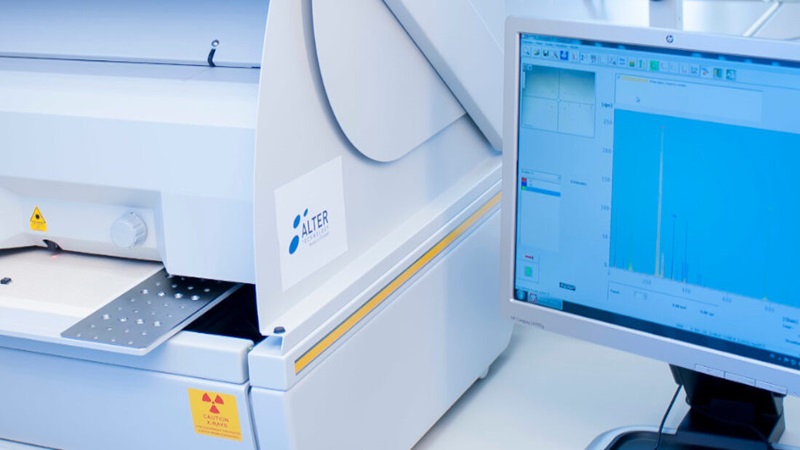

XRF tool enables fast, non-destructive analysis of materials in aerospace and electronics for compliance and quality control.

Combined SAM and stress testing protocols to improve flaw detection and reliability in microelectronic space components.

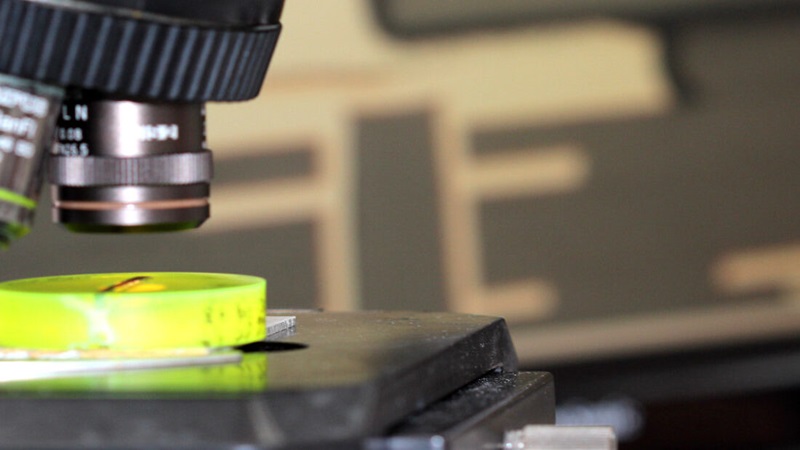

Focused ion beam enables precise material removal and analysis in microelectronics and failure investigations.

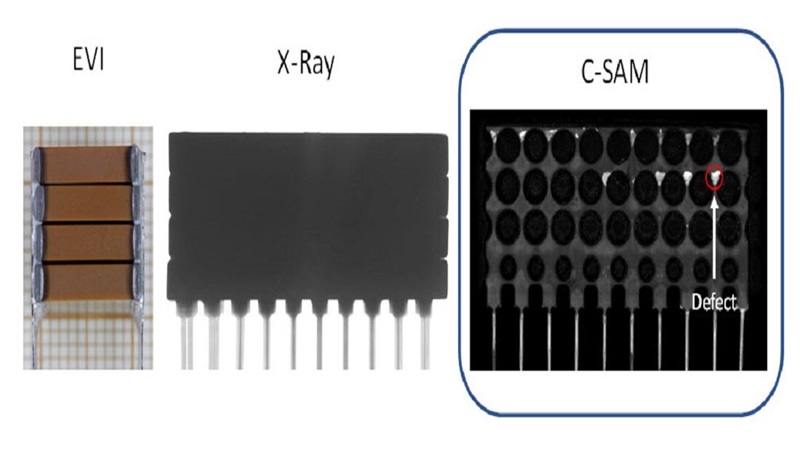

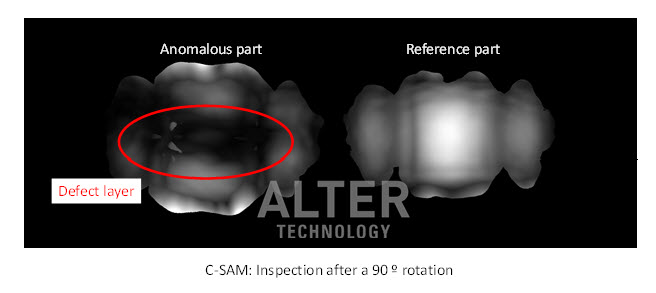

C-SAM inspection reveals interface anomalies in horizontally stacked capacitors by using high-frequency acoustic imaging.

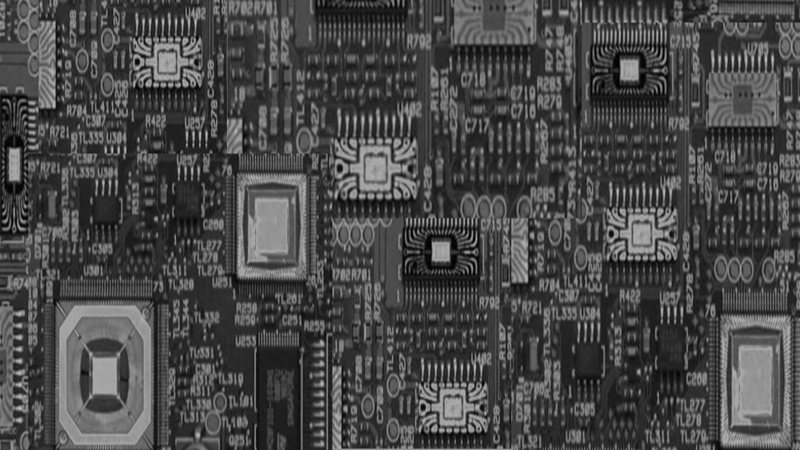

Thick plastic encapsulated parts require multi-depth confocal imaging to detect delamination, voids, and internal structural defects.

Glassivation layer testing ensures dielectric integrity over aluminum to prevent defects like cracks, pinholes, and electromigration.

Plastic encapsulated parts pose risks like delamination and voids; SAM detects internal flaws non-destructively with high sensitivity.

Material analysis identifies elements in microelectronic parts to ensure compliance, reliability, and detection of prohibited materials.

Ultrasonic examination detects submicron internal defects in ceramic capacitors, ensuring reliability through non-destructive analysis.

COTS parts undergo safe C-SAM inspection using deionized water, limited immersion, and drying to prevent corrosion and damage.

Decapsulation exposes internal device structures for analysis of die, interconnects, and defects during failure investigations.

Hermeticity testing detects seal integrity in components to prevent contamination and ensure long-term device reliability.

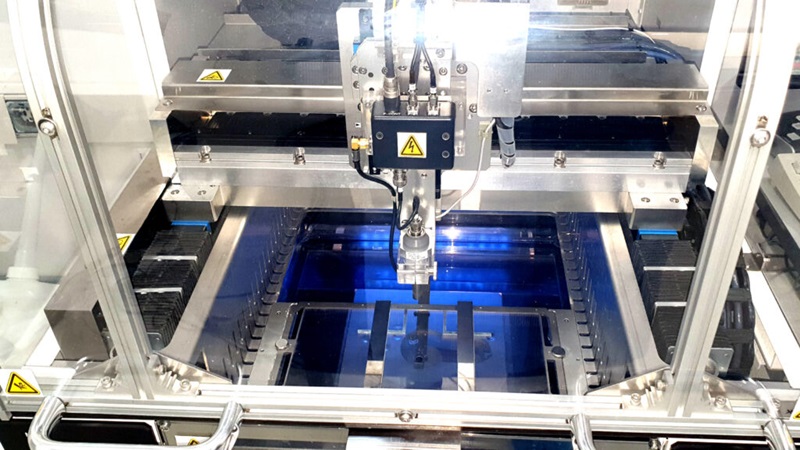

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

C-SAM enables non-destructive inspection of microelectronic parts, detecting internal defects across critical applications.