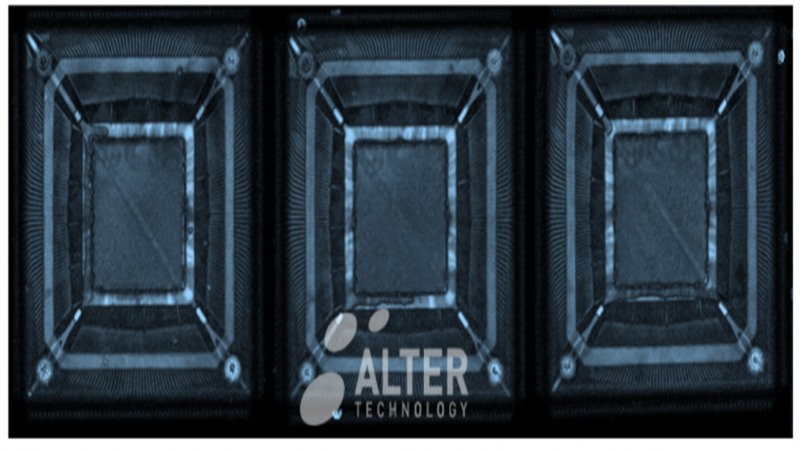

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

C-SAM enables non-destructive inspection of microelectronic parts, detecting internal defects across critical applications.

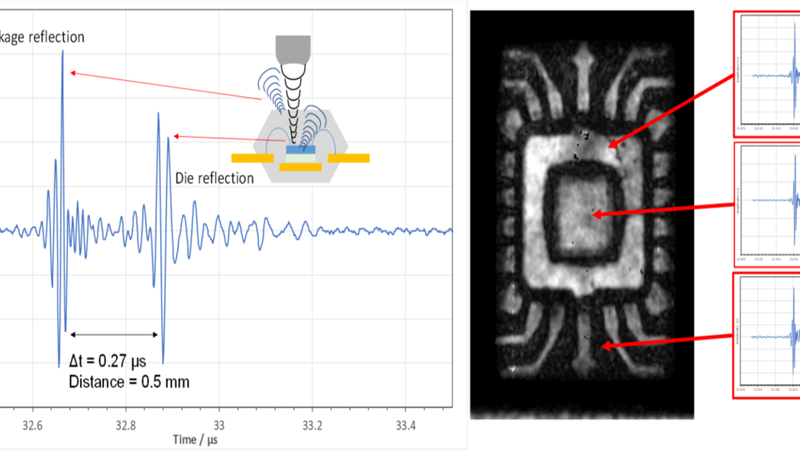

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

SAM enables non-destructive internal inspection of microelectronic parts by analyzing acoustic wave reflections and contrasts.

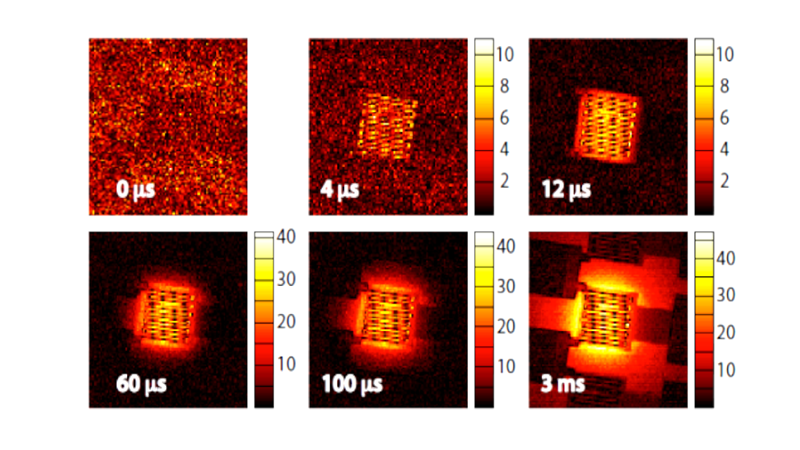

Thermoreflectance Thermal Imaging (TTI) maps micro-scale temperature gradients in devices with high spatial and temporal resolution.

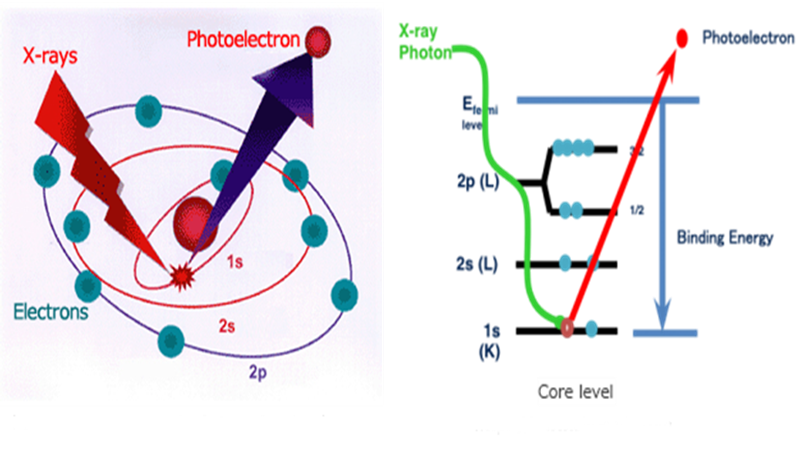

XPS provides precise, non-destructive surface analysis of thin films, revealing elemental composition at nanometer-scale depth.

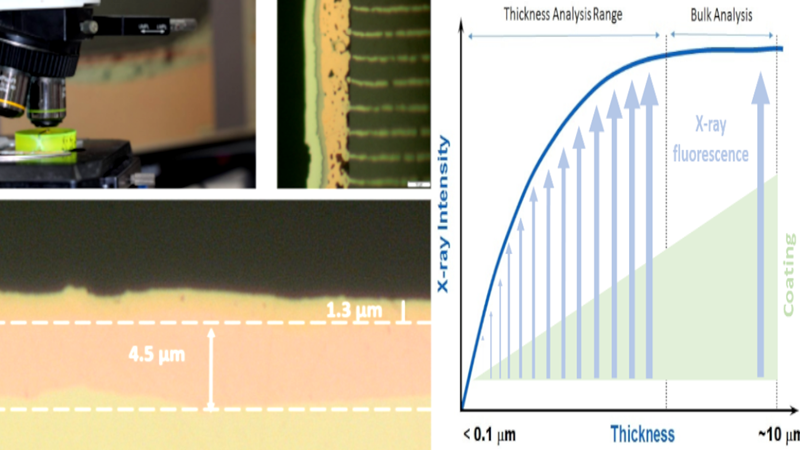

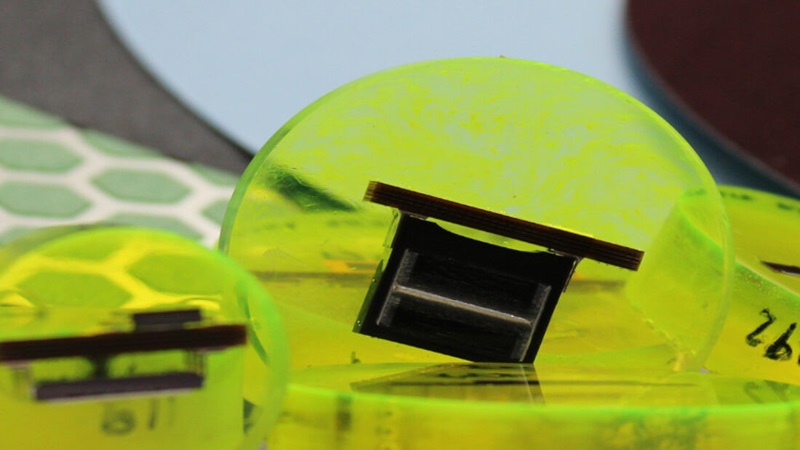

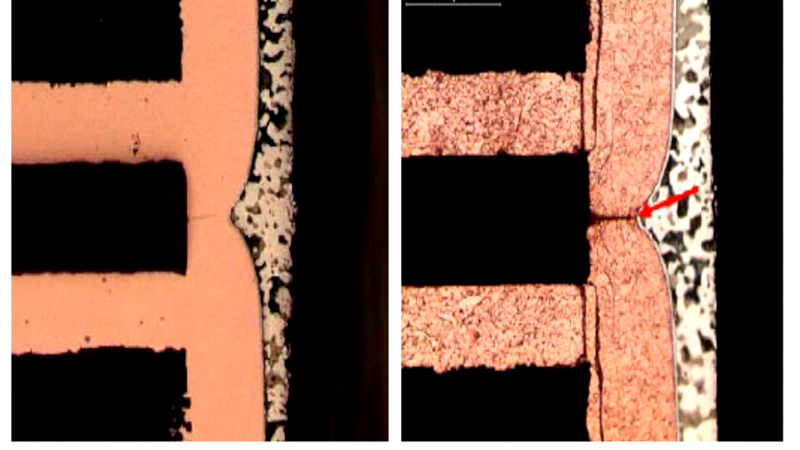

Cross-sectioning reveals internal structures and defects in components through precise grinding and polishing.

X-ray fluorescence enables non-destructive measurement of coating thickness with high precision and reliability.

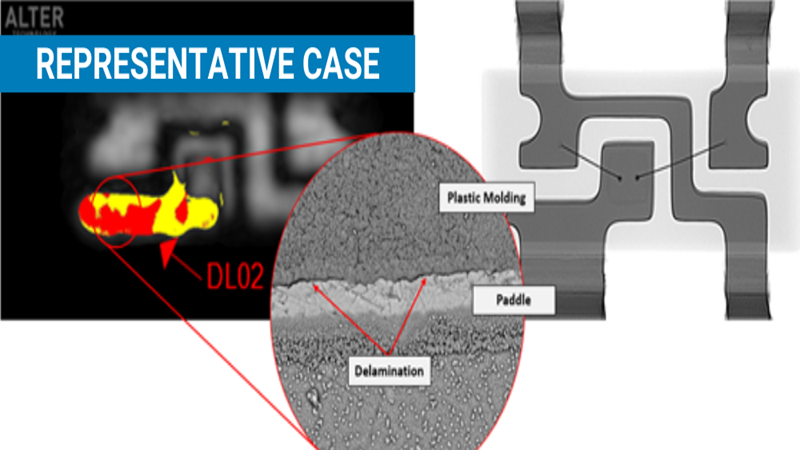

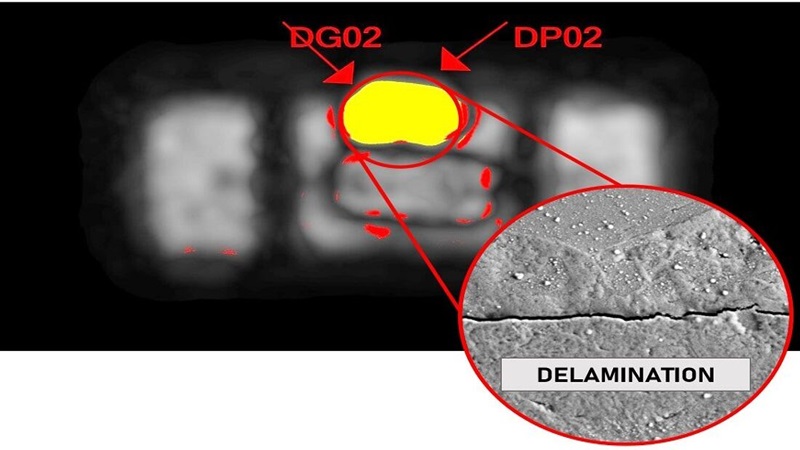

Delamination detection using acoustic microscopy reveals internal defects in plastic components, crucial for high-reliability applications.

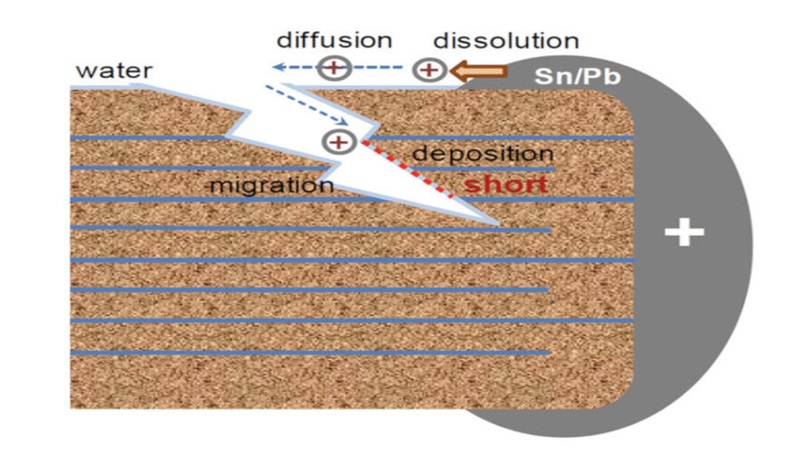

Delaminations in COTS components can lead to mechanical and electrical failures, making inspection essential for space use.

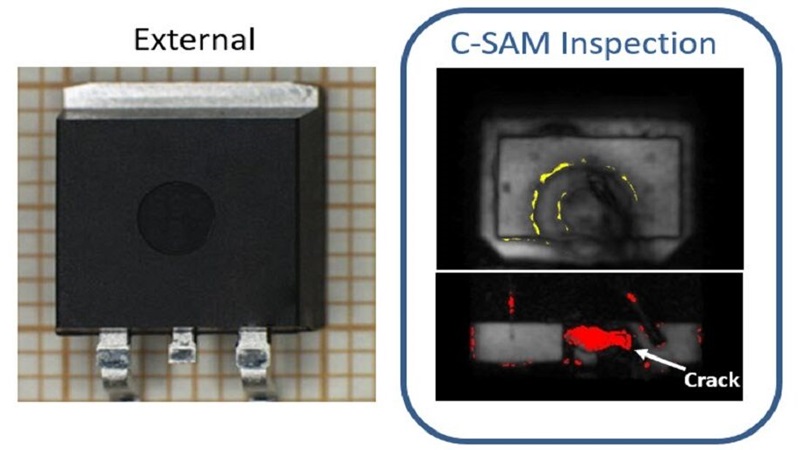

Scanning Acoustic Microscopy enables reliable crack detection in plastic packages, preventing failures in electronic components.

Fluorescence microscopy detects cracks and defects with high sensitivity, enhancing failure analysis in high-reliability electronics.

Microsectioning enables internal inspection of EEE parts, revealing structural defects in PCBs per ESA and industry qualification standards.

Plated Through Via (PTV) reliability depends on plating thickness, voids, and cracks; cross-section analysis ensures structural integrity.

MLCC reliability in space systems is challenged by cracking, often from soldering stress; design and screening help mitigate failures.

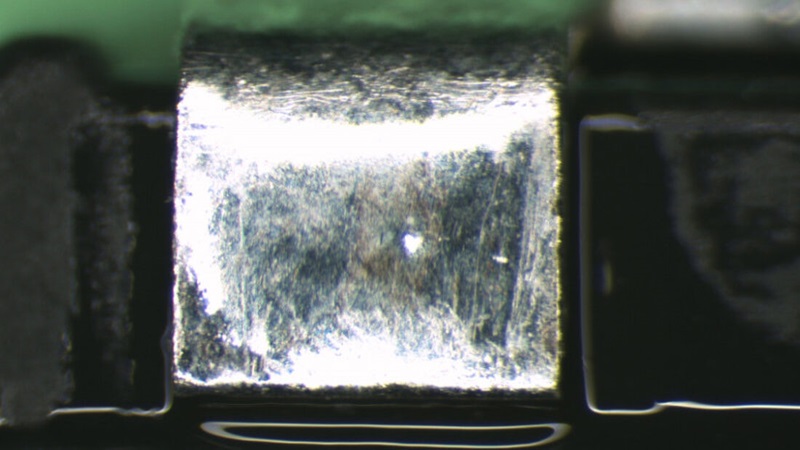

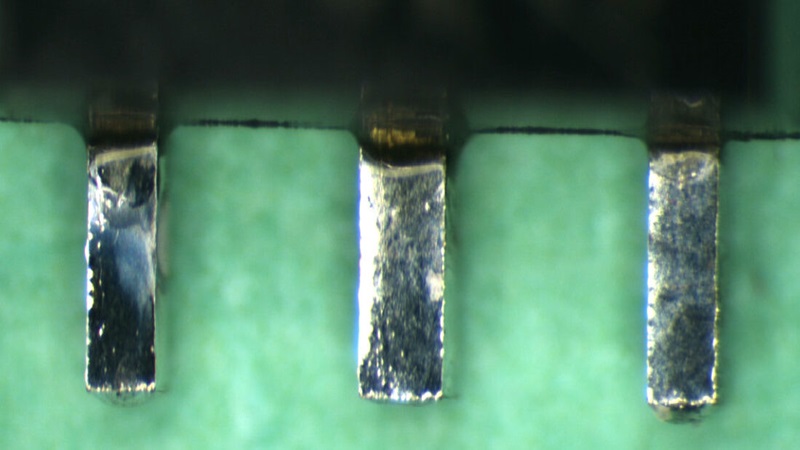

Solderability refers to how well a surface can be wetted by solder, assessed through visual or force-based test methods.

MIL-STD-883 defines solderability testing via Dip and Look to assess termination quality after steam aging and solder dipping.

Explore expert answers on non-destructive inspection techniques for plastic COTS parts using SAM in this Q&A recap.

Non-destructive inspection using acoustic microscopy enhances reliability screening of plastic COTS and electronic systems.

Get expert answers to key questions on CSAM inspections, water use, delamination, and EEE package reliability.