The GRACE project develops SiC radiation sensors for plasma diagnostics, tested at 500°C to ensure fusion reactor suitability.

Blog » EEE Testing »

The GRACE project develops SiC radiation sensors for plasma diagnostics, tested at 500°C to ensure fusion reactor suitability.

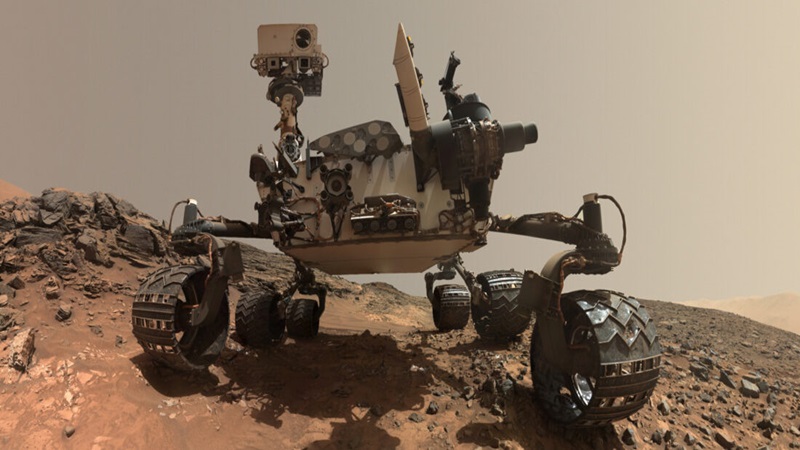

Mars Curiosity rover uses UV photodiodes to monitor surface radiation and support future mission planning.

Overview of mechanical stress methods for lead integrity test in electronic parts, based on MIL-STD-883 and advanced force/fatigue tools.

Life test applies electrical stress to reveal wear-out failures and assess long-term device reliability performance.

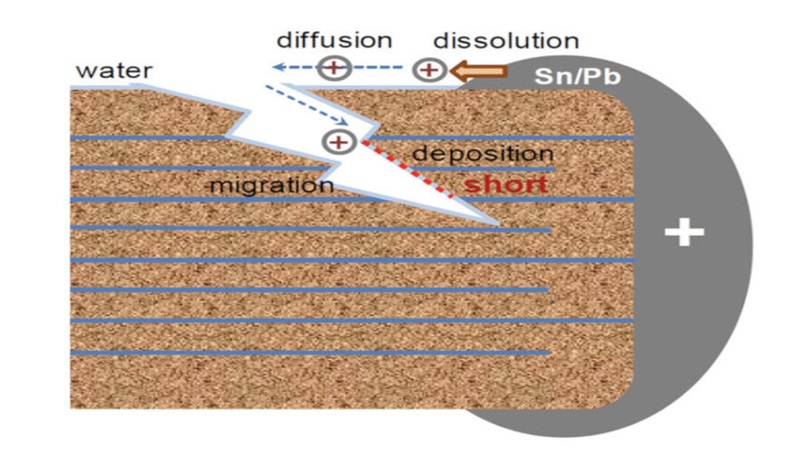

Glassivation layer testing ensures dielectric integrity over aluminum to prevent defects like cracks, pinholes, and electromigration.

Leakage pathway detection uses dye tests to reveal cracks or voids compromising device reliability and sealing.

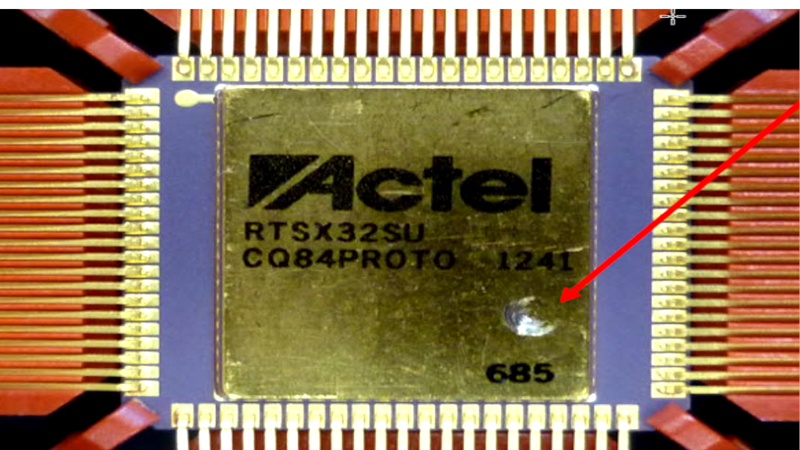

External visual inspection checks EEE parts for defects or damage using optical tools, ensuring compliance with standards.

Non-mechanical optical switches show strong potential for space use, with B-EO and MO technologies performing reliably.

Long term storage of EEE components requires strict controls on environment, handling, and packaging to avoid degradation.

External visual inspection ensures EEE parts quality by identifying critical features and common issues in FPGAs and components per MIL-STD-883 Method 2009.

Incoming inspection ensures part quality by checking materials for non-conformance before inventory or production use.

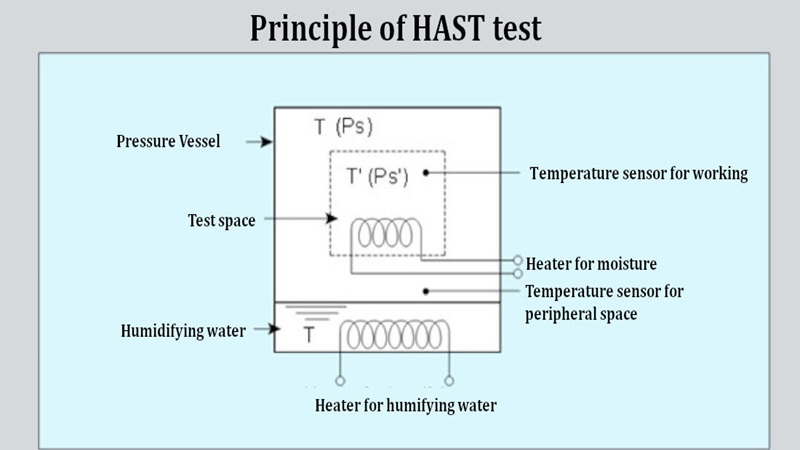

HAST test accelerates humidity reliability checks for electronics, reducing test time while ensuring accurate, representative results.

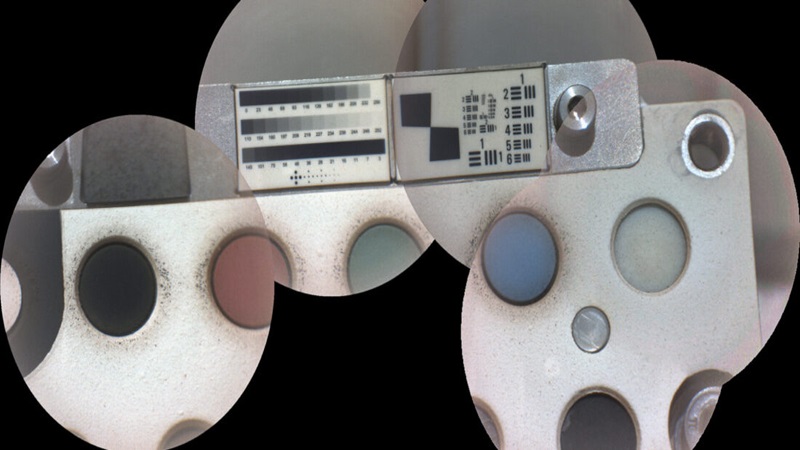

Mars 2020 SuperCam calibration target—key for Mars rover imaging, mineral ID, and instrument health checks.

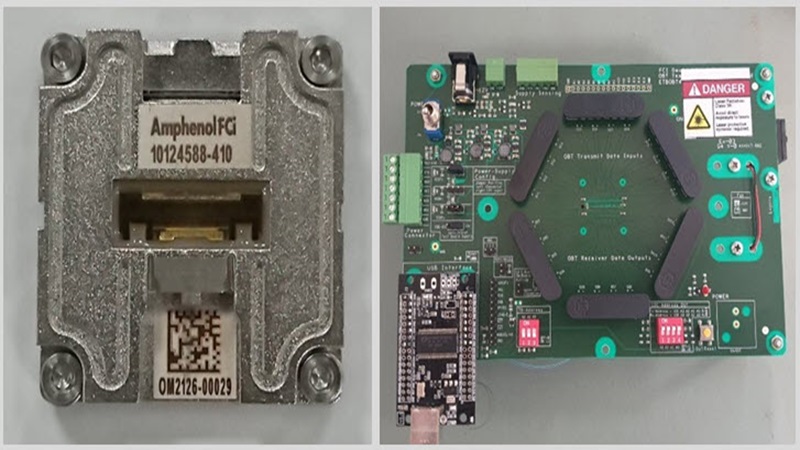

Electro-optical characterization of optical transceivers reveals signal integrity and BER at high-speed data rates.

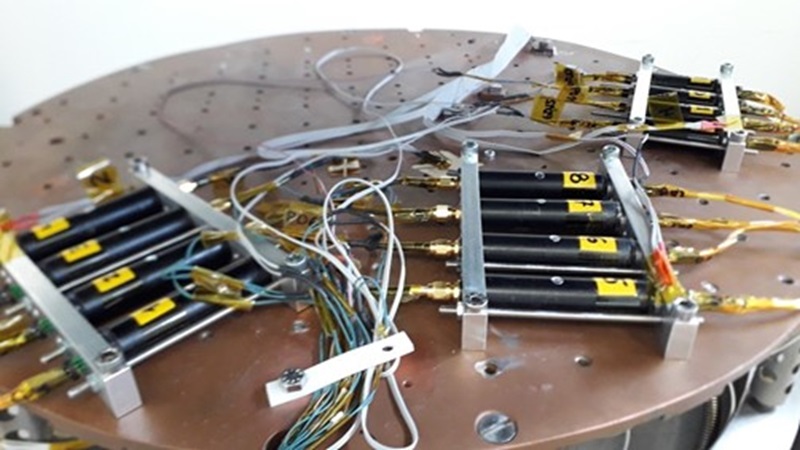

Endurance testing of lasers in vacuum ensures stability, accurate control, and traceability across all wavelengths.

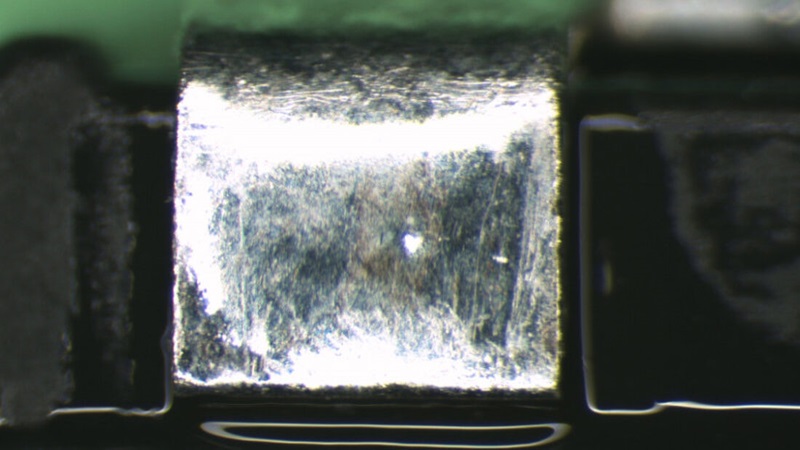

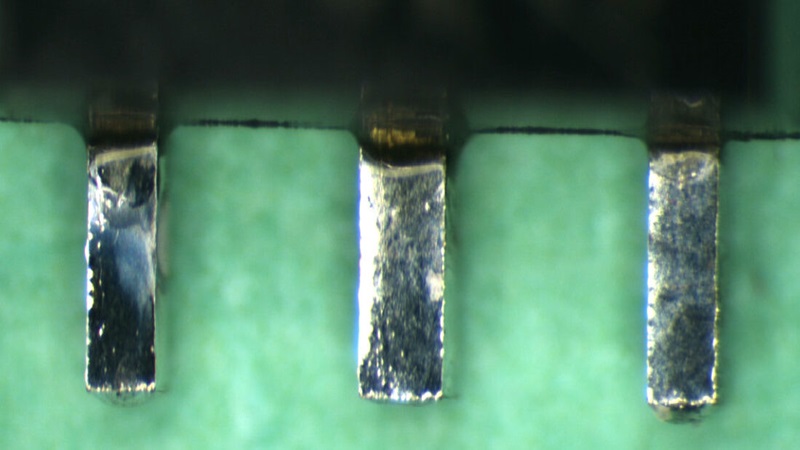

MLCC reliability in space systems is challenged by cracking, often from soldering stress; design and screening help mitigate failures.

A DCL tracks all EEE components used in space systems, detailing specs, approvals, and changes for project validation and review.

A parts approval document defines test, quality, and radiation criteria to certify components for use in space or critical applications.

Solderability refers to how well a surface can be wetted by solder, assessed through visual or force-based test methods.

MIL-STD-883 defines solderability testing via Dip and Look to assess termination quality after steam aging and solder dipping.