The GRACE project develops SiC radiation sensors for plasma diagnostics, tested at 500°C to ensure fusion reactor suitability.

Blog »

The GRACE project develops SiC radiation sensors for plasma diagnostics, tested at 500°C to ensure fusion reactor suitability.

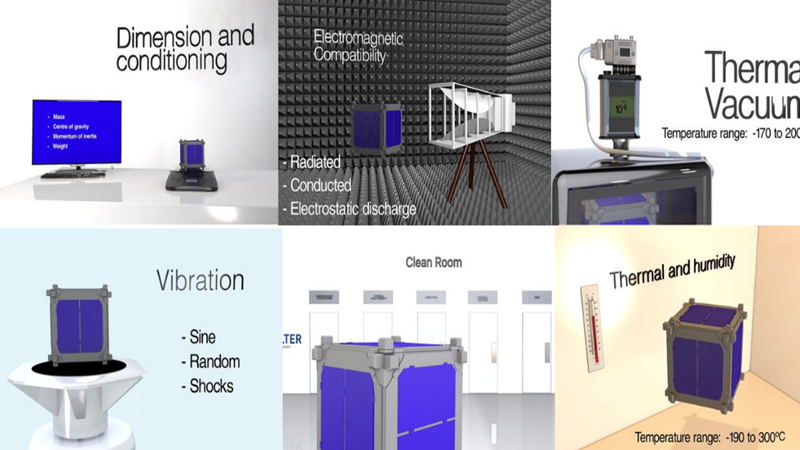

HV optocouplers require thermal vacuum testing to ensure isolation reliability, as vacuum can affect internal gel stability and performance.

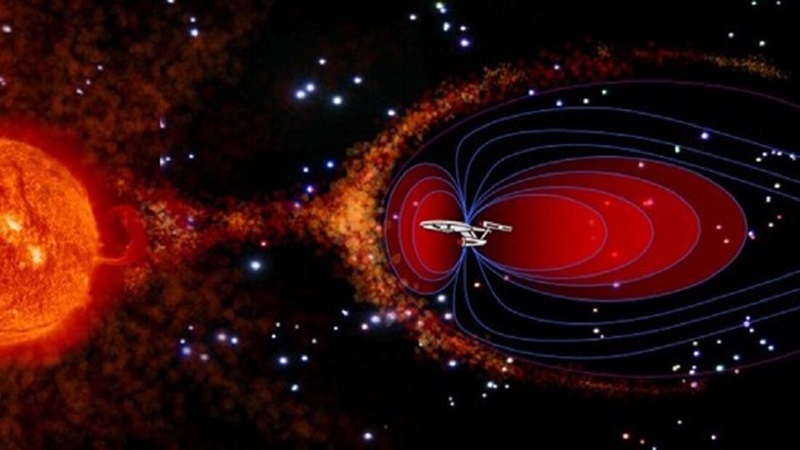

SiC diodes offer high-performance switching for space use, with radiation effects manageable through proper testing and bias control.

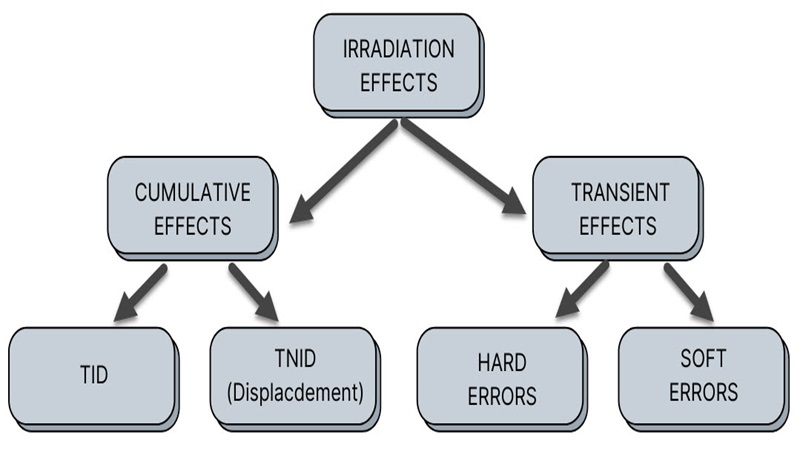

Cumulative effects are gradual effects taking place during the whole lifetime of the electronics exposed in a radiation environment. A device...

TID test standards define irradiation methods, dose rates, and handling to assess component tolerance to total ionizing dose.

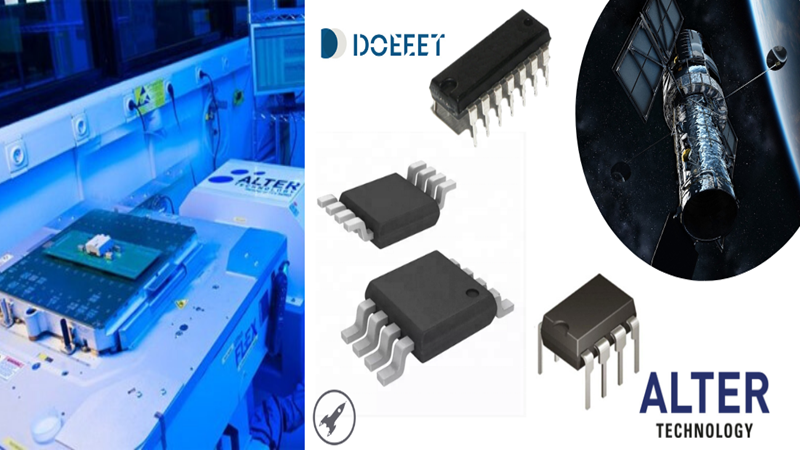

Radiation affects EEE components in space through TID, displacement damage, and single event effects, impacting mission reliability.

Radiation analysis documents component tolerance to space radiation, ensuring compliance with mission-specific exposure levels.

A product assurance plan defines quality, reliability, and component requirements to ensure mission success in New Space projects.

Non-volatile memories retain data without power; endurance and data retention are key for space-grade reliability.

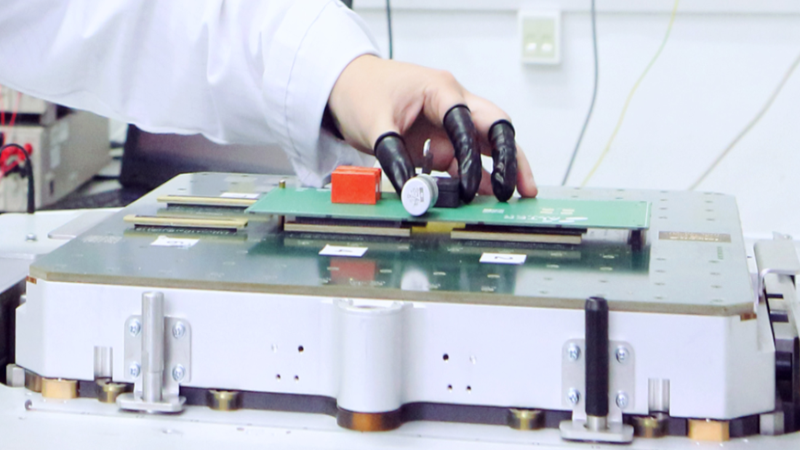

DPA ensures quality and reliability of EEE components by examining design and workmanship through detailed physical analysis.

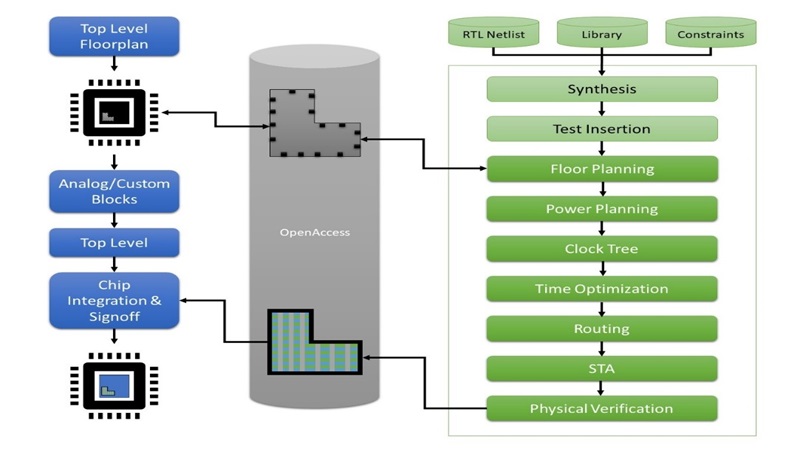

ASIC design focuses on custom integrated circuits for specific functions, with added complexity for space applications.

Electrical test of operational amplifiers monitors key parameters to assess performance under space-related stress conditions.

JUICE mission tested optical fibers under cryogenic cycles to ensure performance for data transfer from Jupiter’s icy moons.

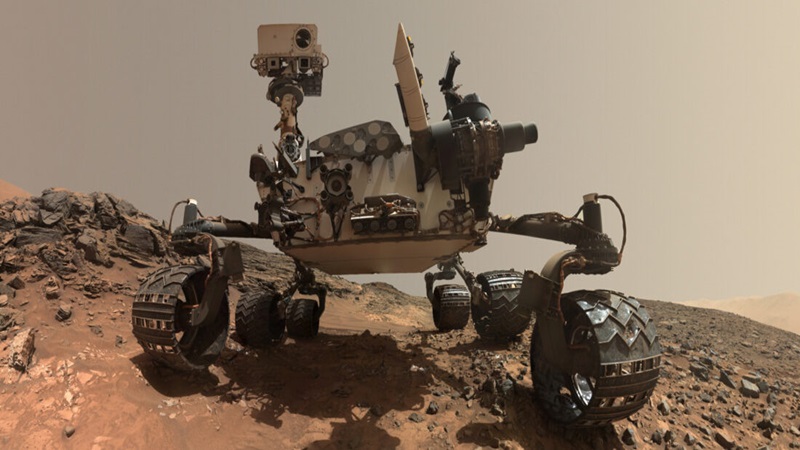

Mars Curiosity rover uses UV photodiodes to monitor surface radiation and support future mission planning.

Strain gages are tested in extreme temperatures and vacuum to assess deformation behavior in critical structures.

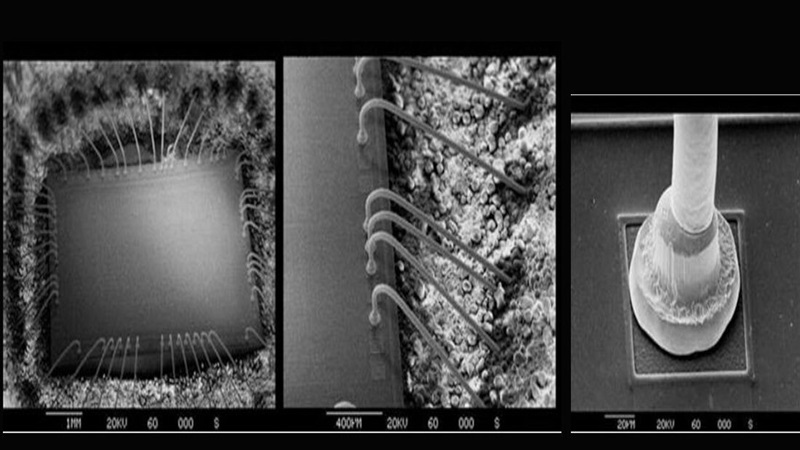

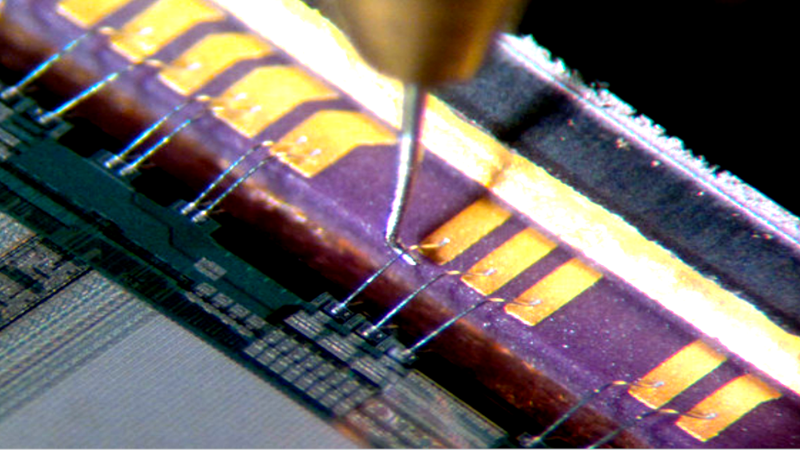

Bond pull test assesses bond strength and reliability under stress to ensure compliance with manufacturing standards.

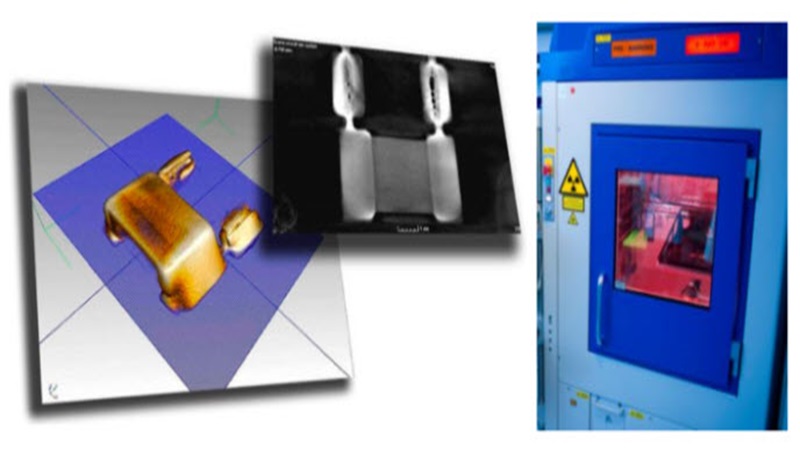

X-ray inspection reveals internal defects in components using non-destructive 2D and 3D imaging techniques.

Electrical test services measure performance of passive and active devices under varied conditions and specifications.

Thermal cycling testing assesses component durability under repeated extreme temperatures to identify thermal stress failures.

Comparison of non-destructive test methods like X-ray, SAM, and lock-in IR used to inspect EEE components and detect internal defects.