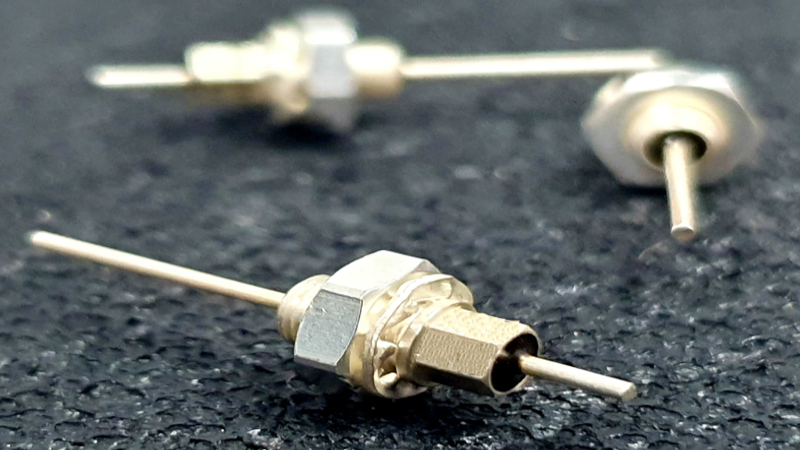

EMI filters for space applications vary in qualification levels, requiring additional testing to ensure compliance and reliability.

Blog » Application »

EMI filters for space applications vary in qualification levels, requiring additional testing to ensure compliance and reliability.

Operational Amplifiers (OpAmp) for space applications must meet strict requirements for temperature, radiation tolerance, and material compliance.

QFN package offers low cost and high performance, but mitigating tin whiskers is crucial for reliability in space applications.

Various manufacturers offer LVDS microcircuits for Space applications, differing in radiation hardening, qualification levels, and export restrictions.

Rakon’s RK105 and RK205 oscillators offer high reliability and radiation tolerance for New Space applications.

Q-Tech’s QT780, QT723, and QT735 series oscillators offer high reliability for LEO applications, built to stringent space standards.

AXTAL offers sourcing and up-screening of quartz crystals for New Space, ensuring high reliability with various screening levels.

Texas Instruments’ Space Enhanced Plastic (SEP) devices offer radiation-tolerant solutions for New Space applications with enhanced reliability.

Renesas offers radiation-tolerant plastic-package ICs, providing cost-effective solutions for short-duration LEO missions.

Analog Devices offers CSL, CSM, and CSH screening flows to balance cost, reliability, and radiation tolerance for New Space applications.

Microchip offers plastic rad tolerant MCUs, balancing cost, reliability, and radiation resistance for aerospace and New Space applications.

Microchip enhances radiation tolerance in MCUs, ensuring reliability for aerospace applications with improved immunity to space radiation.

EEE componentes play a key role in space power systems, balancing efficiency, voltage regulation, and weight reduction challenges.

Flux is ESA-qualified for custom magnetics under ESCC3201/013, ensuring high reliability for Space applications.

We have previously talked about the revolution that the Space business is currently experiencing, with New Space being a key player in it. To adapt...

Parts selection is crucial in Space applications, balancing performance, availability, quality, and lead time to ensure design feasibility.

Product Assurance Support ensures compliance with reliability, safety, and quality standards in space missions, minimizing failure risks.

Parts Procurement Control Parts (PPCP) ensures EEE components meet quality, reliability, and procurement standards in space projects.

The main challenge for EEE parts performing on Space projects is to withstand the extreme and harsh environment they must work in. This involves...

A detail specification defines requirements for procuring parts, ensuring compliance with mechanical, electrical, and testing standards.