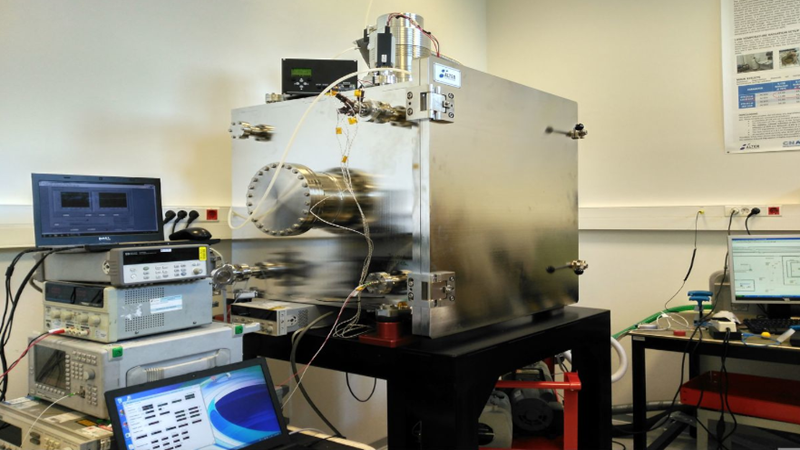

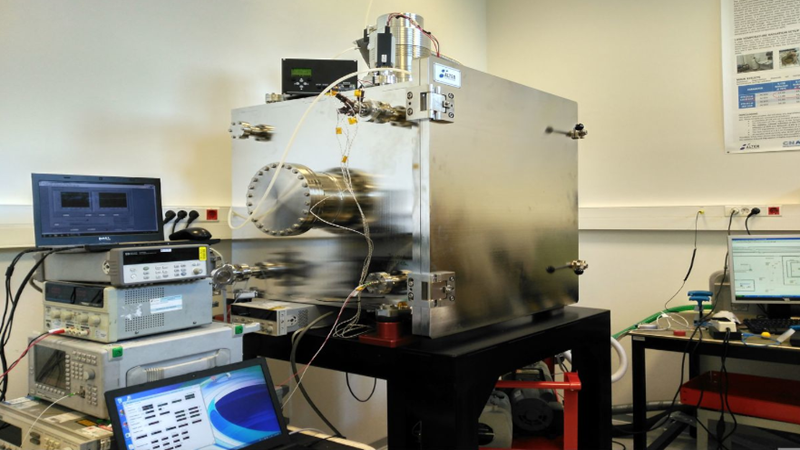

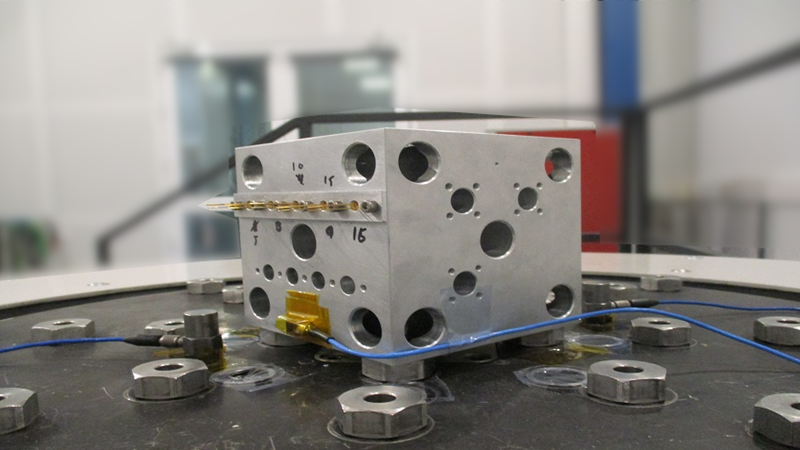

Thermal Vacuum Testing ensures space components withstand extreme cold, heat, and ultra-high vacuum environments.

Blog » Application »

Thermal Vacuum Testing ensures space components withstand extreme cold, heat, and ultra-high vacuum environments.

Space-grade SSD solutions combine NAND flash and radiation-tolerant controllers to ensure data integrity in harsh space environments.

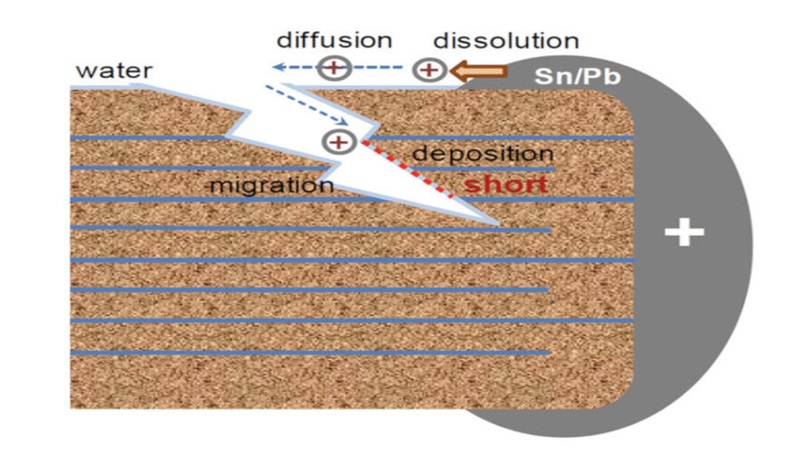

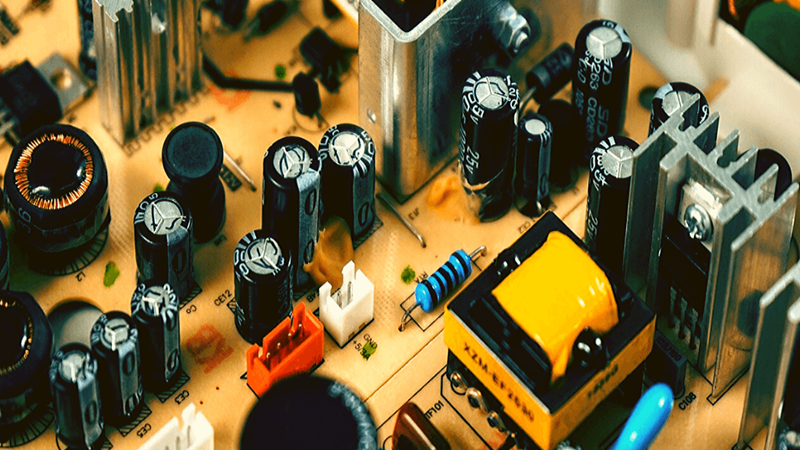

MLCC reliability in space systems is challenged by cracking, often from soldering stress; design and screening help mitigate failures.

A DCL tracks all EEE components used in space systems, detailing specs, approvals, and changes for project validation and review.

A parts approval document defines test, quality, and radiation criteria to certify components for use in space or critical applications.

Single event latch-up in space electronics causes destructive currents; mitigation requires protection and recovery circuitry.

Low Voltage Differential Signaling (LVDS) enables high-speed, low-power data transmission with strong noise immunity and low EMI.

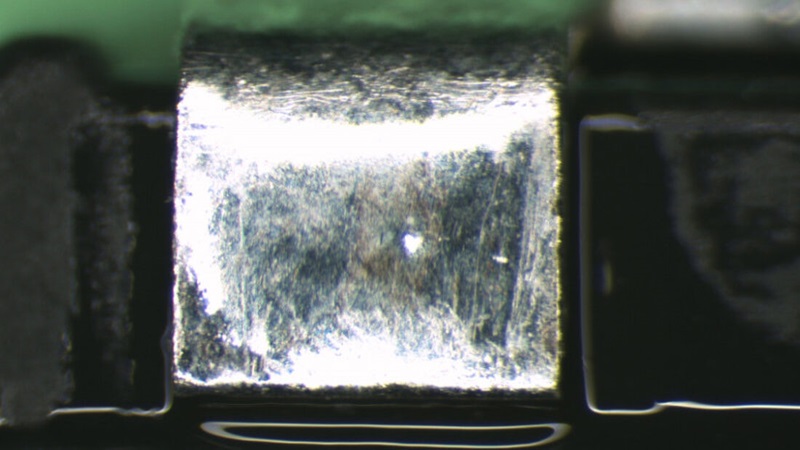

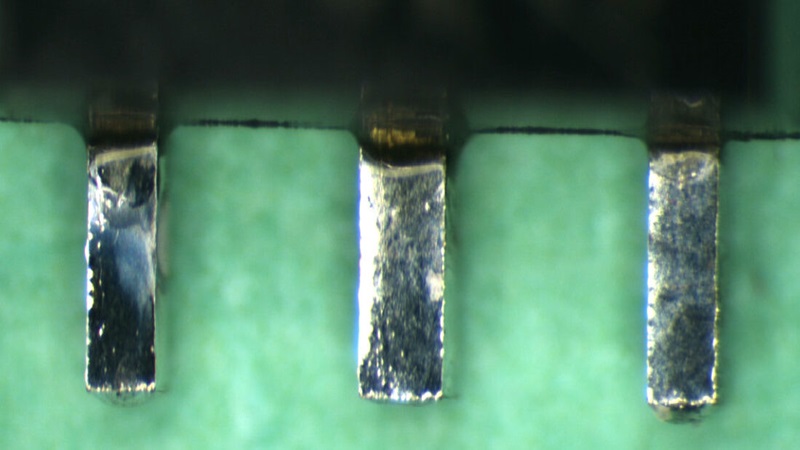

Solderability refers to how well a surface can be wetted by solder, assessed through visual or force-based test methods.

MIL-STD-883 defines solderability testing via Dip and Look to assess termination quality after steam aging and solder dipping.

Image sensors convert photons into electronic signals, with key parameters like responsivity, SNR, and dark current analyzed.

Lot Acceptance Test (LAT) verifies a component batch’s reliability through screening and endurance tests before final application use.

Acceptance Quality Limit (AQL) defines the maximum defect rate allowed in a batch based on statistical sampling.

Phototransistor optocouplers enable isolation in DC circuits, offering signal transfer with galvanic separation.

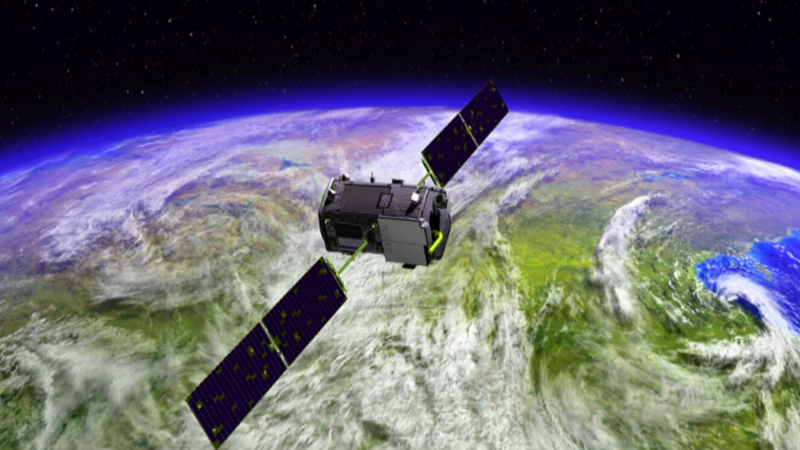

CubeSats face policy gaps, high failure rates, and growing debris concerns, highlighting the need for technical oversight.

Automotive components in COTS require careful evaluation beyond grade labels to ensure suitability for space use.

This session addresses the challenges in selecting EEE components for cost-effective space missions, particularly those in LEO.

Webinar addresses how optoelectronic parameters behave under stress and their suitability for space applications.

Explore expert answers on product assurance, COTS use, packaging, and certification from our New Space webinar Q&A session.

Webinar explores product assurance strategies to boost reliability in New Space missions using COTS components.

Rad-hard integrated current limiter RHRPMICL1A supports 100V+ power buses with QML-V qualification for space use.