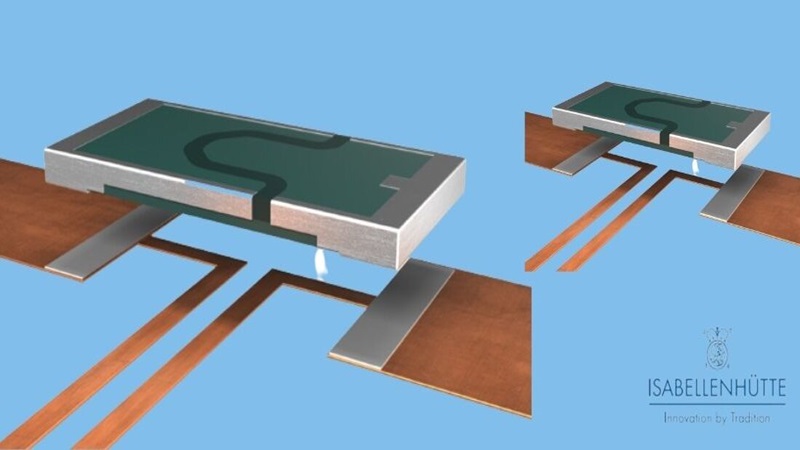

Precision resistor selection ensures accurate current sensing and reliability in high-performance aerospace systems.

Blog » Application »

Precision resistor selection ensures accurate current sensing and reliability in high-performance aerospace systems.

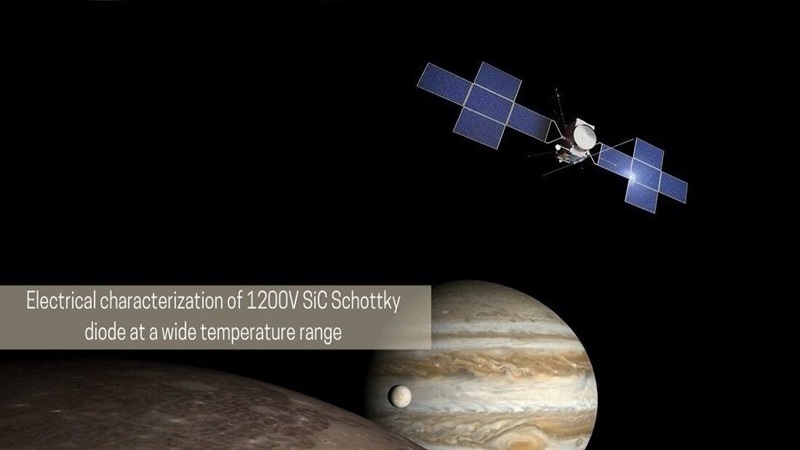

1.2kV SiC Schottky diode enables efficient, compact, and high-reliability power systems for space applications.

Electrical characterization of SiC diodes shows reliable performance under high temperatures and varying voltage conditions.

Explore evolving definitions of rad-hard components and how radiation effects shape semiconductor selection in modern satellite systems.

Explore rad-hard, enhanced, and commercial strategies for satellite design and how each balances cost, risk, and radiation resilience.

This article explores five SRAM memory design approaches for achieving a 16 Mbit memory bank in space systems, comparing traditional...

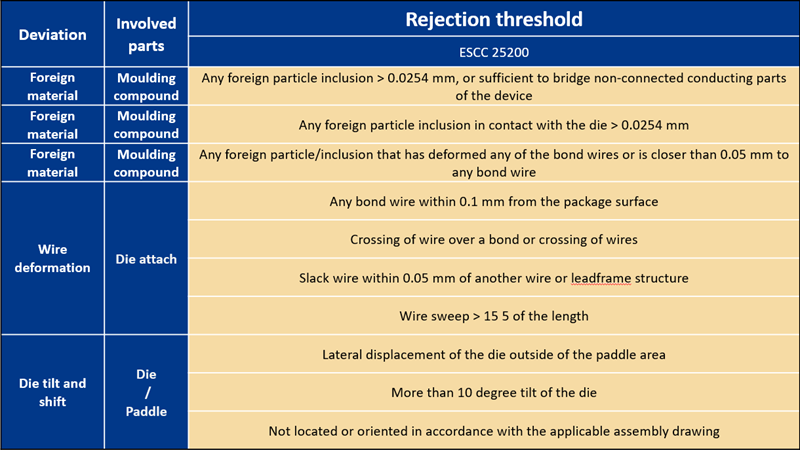

Comparison of SAM rejection criteria across IPC, ESCC, MIL-STD, and NASA specs for cracks, voids, delamination, and contamination.

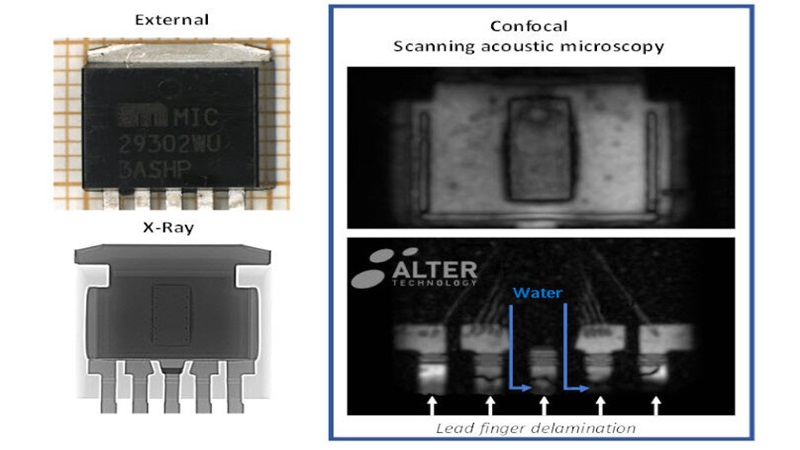

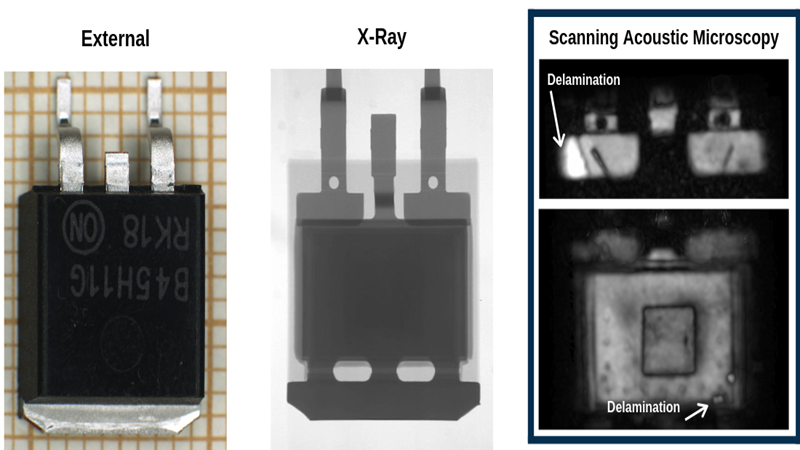

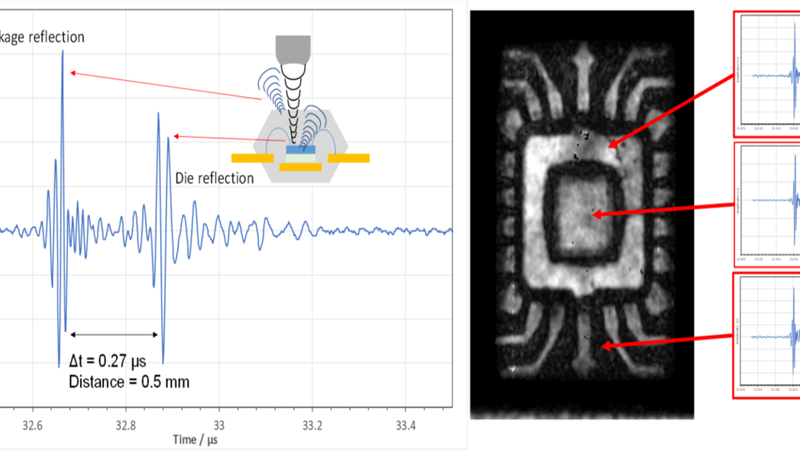

Scanning acoustic microscopy (SAM) detects water ingress paths and hidden flaws in delaminated parts of microelectronic systems.

Combined SAM and stress testing protocols to improve flaw detection and reliability in microelectronic space components.

Focused ion beam enables precise material removal and analysis in microelectronics and failure investigations.

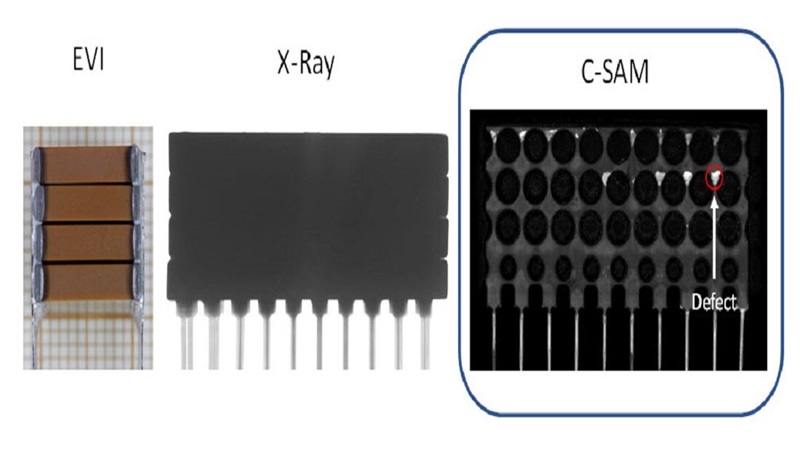

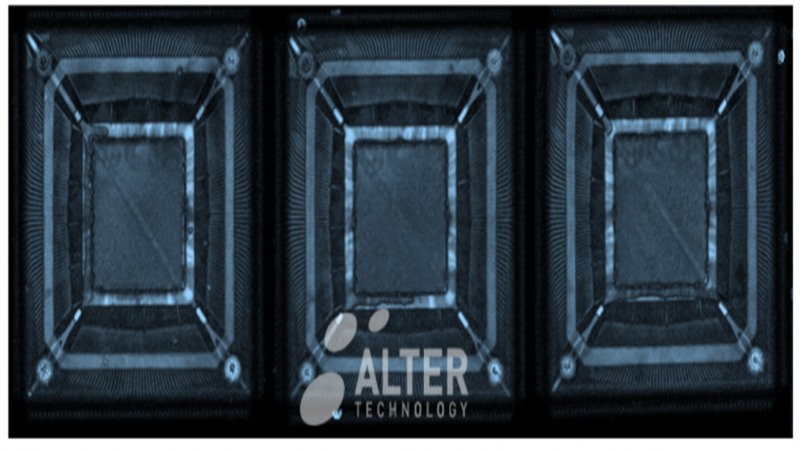

C-SAM inspection reveals interface anomalies in horizontally stacked capacitors by using high-frequency acoustic imaging.

Thick plastic encapsulated parts require multi-depth confocal imaging to detect delamination, voids, and internal structural defects.

Plastic encapsulated parts pose risks like delamination and voids; SAM detects internal flaws non-destructively with high sensitivity.

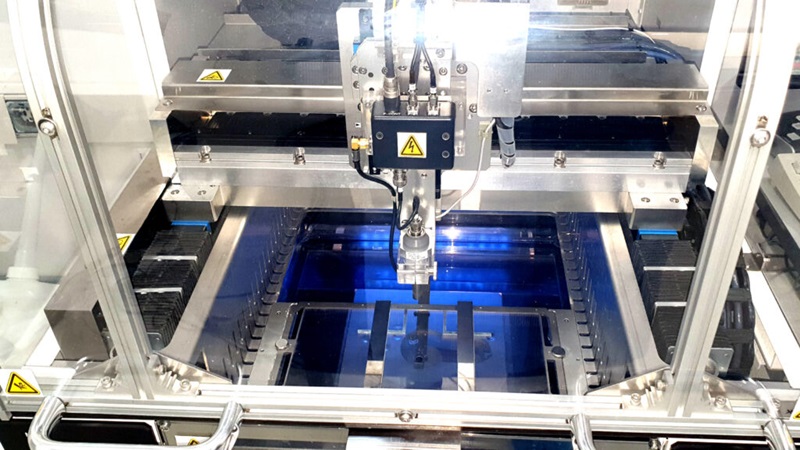

COTS parts undergo safe C-SAM inspection using deionized water, limited immersion, and drying to prevent corrosion and damage.

C-SAM inspection reveals internal defects like voids and delamination in encapsulated microelectronic components with precision.

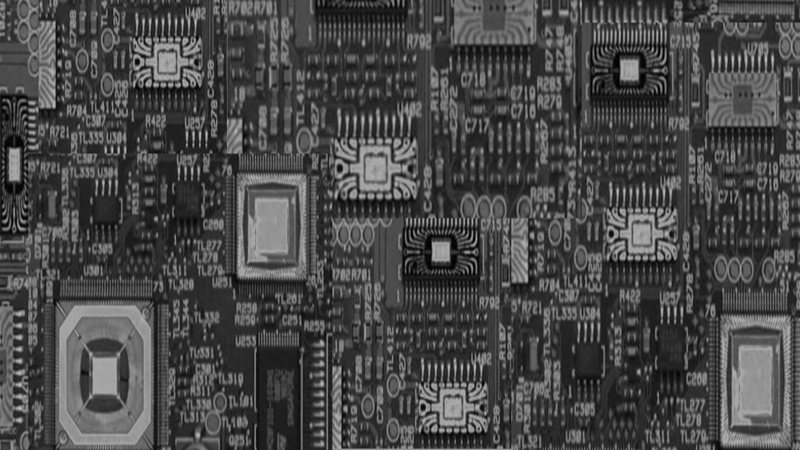

C-SAM enables non-destructive inspection of microelectronic parts, detecting internal defects across critical applications.

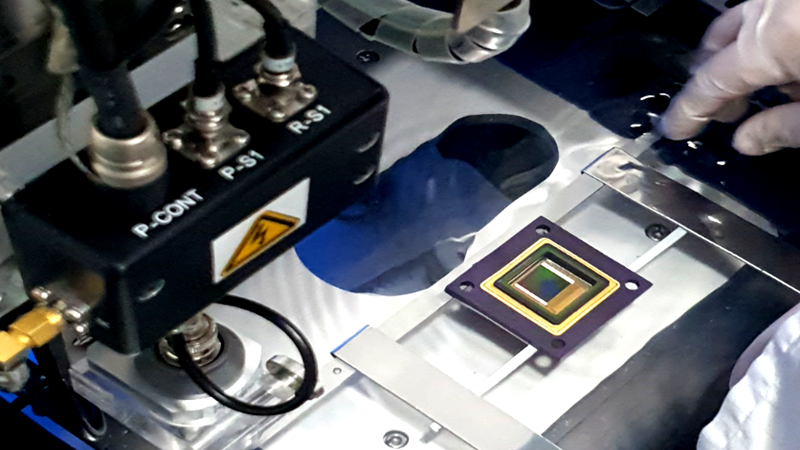

Scanning Acoustic Microscopy (SAM) enables high-resolution, non-destructive imaging of internal structures and defects in layered systems.

SAM enables non-destructive internal inspection of microelectronic parts by analyzing acoustic wave reflections and contrasts.

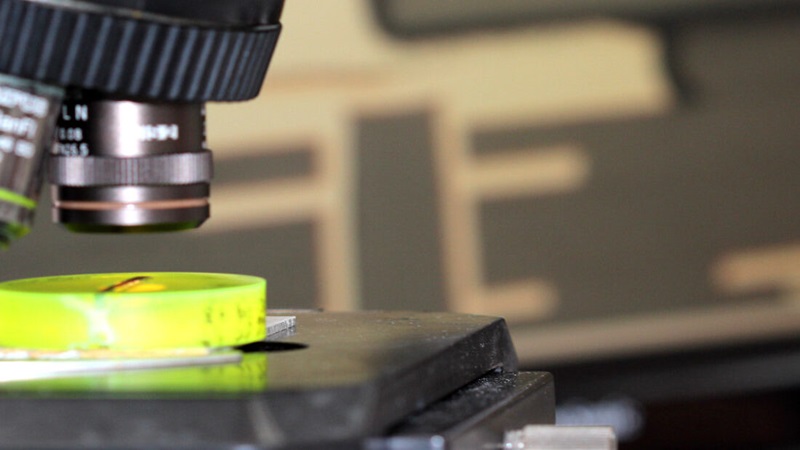

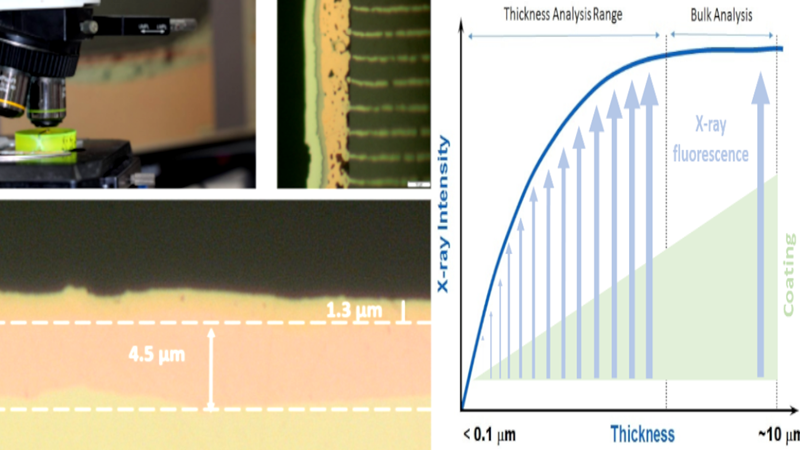

Cross-sectioning reveals internal structures and defects in components through precise grinding and polishing.

X-ray fluorescence enables non-destructive measurement of coating thickness with high precision and reliability.