This article is the fifth part of a complete installment on the construction, application, and features of film and foils organic dielectric capacitors, divided into 6 sections:

- Introduction to film capacitors

- Evolution and applications of paper capacitors

- Polyester PET /KT/MKT capacitors

- Polypropylene PP / KP and MKP Capacitors

- Polycarbonate (PC) capacitors / KC and MKC

- Polystyrene PS, Polyphenylene sulfide PPS and other plastic film capacitors Teflon PTFE / Polysulfone PSU

For a long time, the polycarbonate capacitor has been predominant among metalized precision capacitors. Nowadays, however, the PP capacitor has taken over more and more applications from the PC. Where one has been able to disregard the TC differences the foil design of the PC often has replaced polystyrene PS but also here PP capacitors are replacing those of polystyrene. The manufacture of PC film, therefore, is declining and will eventually cease. We shall have a closer look at the reasons and characteristics.

Introduction

The polycarbonate film is unlike other plastic films prepared from a dried emulsion. Its least thickness is stated to be 1.5 μm (0.06 mils), and its εr to 3.0 at 1 kHz and room temperature. This film has small dielectric losses, a high IR, a small temperature dependence, and a maximum temperature specified by many manufacturers as +125 °C. Thus it was rapidly popular, not least in precision capacitors.

Because there is a certain risk of increasing IR failures above +100 °C, we recommend this ambient as a maximum or not more than that of the manufacturer’s data sheet if they specify a lower temperature.

Genuine SMD designs are missing, but there are examples of broad spread-out metal strap terminals reminding of the Gullwing design. But check if it is a single source situation.

Temperature and frequency dependencies

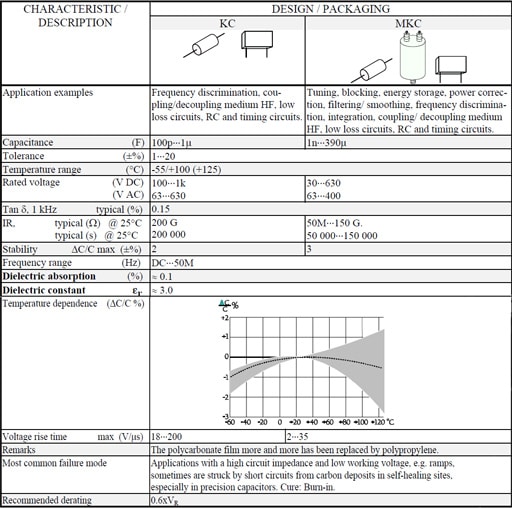

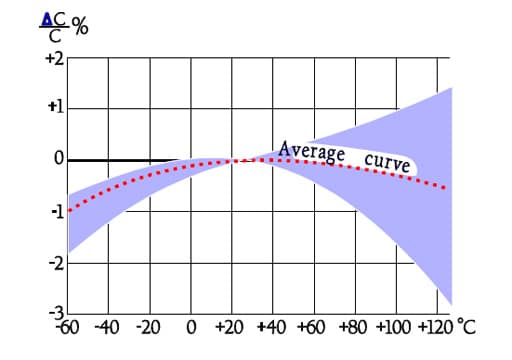

Figure 34. Typical curve range for capacitance versus temperature in PC capacitors KC and MKC designs

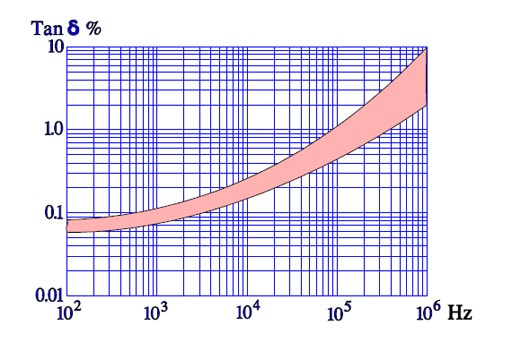

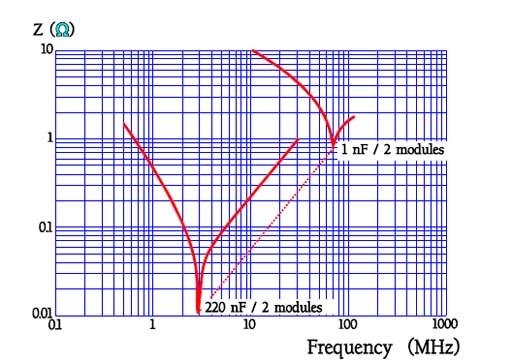

Figure 37. Typical dependence of Tanδ versus frequency in PC capacitors KC and MKC.

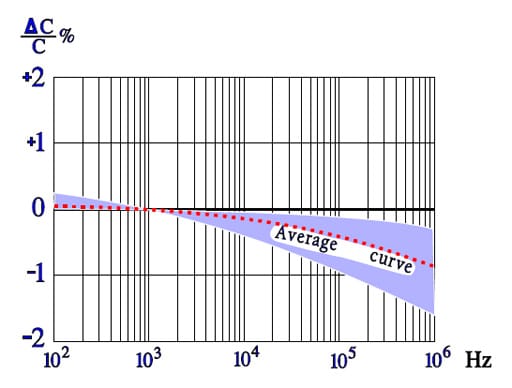

Figure 35. Typical curve range for capacitance versus frequency in PC capacitors KC and MKC designs.

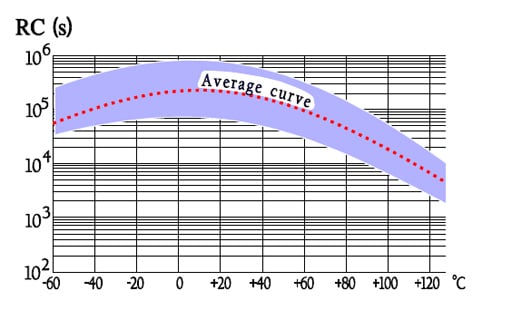

Figure 38. Typical function of RC versus temperature in PC capacitors KC and MKC capacitors.

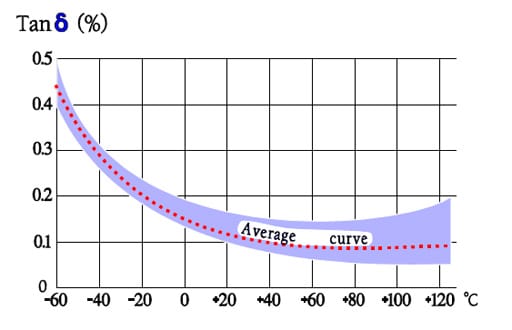

Figure 36. Typical curve range for Tanδ versus temperature in PC capacitors KC and MKC designs.

Figure 39. Typical function of RC versus temperature in PC capacitors KC and MKC with 2 modules.

Failure modes

Some mysterious short-circuiting failures were reported from precision capacitors in high impedance low voltage space applications. In 1982 a Voyager satellite was met with a failure in an 8 μF/ 75V polycarbonate capacitor. Halfway to Jupiter, the IR suddenly dropped from hundreds of MΩ to 2.8 kΩ. All over the world, component experts worked with this kind of problem, and by and by, the picture became clearer. The reasons are resulting effects of self-healing.

The issue is a critically high carbon deposit in former self-healing sites, which is connected with the high carbon contents in the polycarbonate film. However, the failure only appears in that very narrow application sector where precision capacitors are usually used at low voltages and in high impedance circuits, e.g., integration and ramp voltages. Even that deficient energy needed to burn away the formed carbon string may be missing. The cure is some kind of Burn-in treatment. From a failure rate in the magnitude of, say, one per cent, we should get down to or below one per thousand. We find the most sophisticated (and expensive) Burn-in program in US MIL-C-87217. In conclusion, it is built on a collection of all those environments that release this kind of short circuit: cyclic voltage ramps with polarity changes + gradual temperature fluctuations.