This article is the first part of a complete installment on the construction, application, and features of film and foils organic dielectric capacitors, divided into 6 sections:

Film capacitors are essential electrostatic capacitors suitable for medium, higher voltage, and higher current circuits. Unlike most dielectric systems, film capacitors feature a low loss factor at shallow temperatures.

The dielectric constant is not big, but they feature very high dielectric strength. Combined with long life and self-healing aging capabilities, they are ideal for high voltage, high power systems. While we focus on the most common dielectric types, there is a comprehensive list of organic dielectric materials with different features.

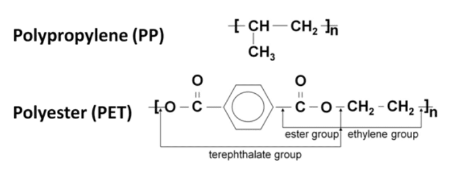

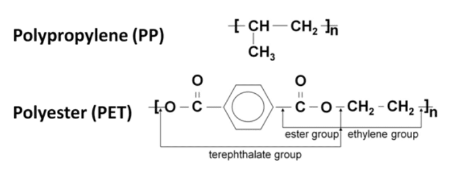

The most common dielectric materials used in the construction of plastic film capacitors are polypropylene and polyester. Other dielectrics used in the construction of film capacitors include polycarbonate, polystyrene, polytetrafluoroethylene (PTFE), polyethylene naphthalate (PEN), polyphenylene sulphide (PPS), polyimide, and paper as discussed in next chapters in more details.

Polyester (PET)

Polyester has a high dielectric constant compared to polypropylene, and is one of the most widely used dielectric materials. This high dielectric constant allows construction of capacitors with small physical sizes. Polyester capacitors, also known as mylar capacitors, have good self-healing properties and are relatively cheap.

At high temperatures, polyester capacitors dissipate more power. This characteristic makes these capacitors unsuitable for high-frequency and high-current AC applications. Furthermore, polyester exhibits a significant capacitance change, up to 5%, as temperature approaches low or high-temperature limits. Due to this characteristic, polyester is an unsuitable material for constructing precision capacitors. Polyester capacitors are mostly used in general-purpose board-level applications such as blocking, bypassing, decoupling, and some noise suppression circuits.

Polypropylene (PP)

Polypropylene is commonly used in the construction of capacitors for high-frequency AC applications. This dielectric material has a low dissipation factor, high breakdown strength, low dielectric absorption, and high insulation resistance and is readily available. These properties make polypropylene a dielectric material of choice for a wide range of applications, including snubber circuits, high-frequency AC systems, high-voltage DC & AC systems, and high-current DC applications.

Polypropylene capacitors can operate over a wide temperature range. Unlike polyester capacitors, their capacitance decreases with temperature. Due to their temperature characteristics, polypropylene capacitors are commonly used to complement polyester capacitors. This is achieved by connecting a polyester capacitor and a polypropylene capacitor in parallel.

Despite its impressive properties, polypropylene has a lower dielectric constant than polyester. In addition, this material is not available in thin-gauge films. Compared to polyester, polypropylene is more expensive and is not a suitable material when physical size of a component is a key consideration.

Polyphenylene sulphide (PPS)

Polyphenylene sulphide has excellent temperature characteristics and is commonly used for constructing precision capacitors. The capacitance of these capacitors does not vary significantly with changes in temperature. PPS capacitors are commonly used to replace polycarbonate capacitors in electronic circuits. The dielectric constants of these two materials are similar, and both have high breakdown strength.

Polytetrafluoroethylene (PTFE)

PTFE capacitors, also known as Teflon capacitors, are low loss capacitors that offer excellent stability. PTFE has a relatively low dielectric constant, around 2.1, and it is, therefore, unsuitable for constructing components with small footprints. Teflon capacitors are suitable for high temperature applications and can be used in systems that expose components to temperatures of up to 200oC. PTFE capacitors have low capacitance values and are relatively expensive.

Polystyrene (PS)

Polystyrene capacitors exhibit extremely low loss and high capacitance stability over temperature, typically down to ±1% 0ver the range -55°C to +85°C. It’s low dielectric constant of 2.1 makes in suitable for low capacitance, high stability applications such as timing circuits.

Polyimide (Kapton)

Polyimide has a high dielectric constant, around 3.4, and it is commonly used for constructing components for high temperature applications. Kapton capacitors can be used in systems that can expose components to temperatures of up to 250oC. Metallized polyimide capacitors have poor self-healing characteristics.

Polycarbonate (PC)

Polycarbonate has an average dielectric constant, around 2.7, and it is commonly used in the construction of capacitors for high temperature applications. Polycarbonate capacitors are low loss components that have good electrical characteristics over a wide temperature range. Polycarbonate capacitors were widely used in military applications. However, polycarbonate film has limited availability, and is not recommended for new designs.

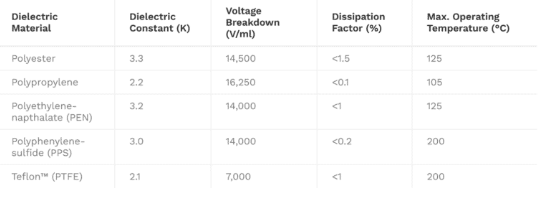

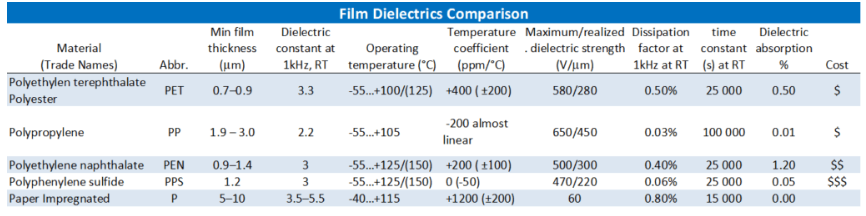

The table below summarises some characteristics of common plastic film dielectrics.

Polycarbonate (PC)

Polycarbonate has an average dielectric constant, around 2.7, and it is commonly used in the construction of capacitors for high temperature applications. Polycarbonate capacitors are low loss components that have good electrical characteristics over a wide temperature range. Polycarbonate capacitors were widely used in military applications. However, polycarbonate film has limited availability, and is not recommended for new designs.

The table below summarises some characteristics of common plastic film dielectrics.

Applications & Designs

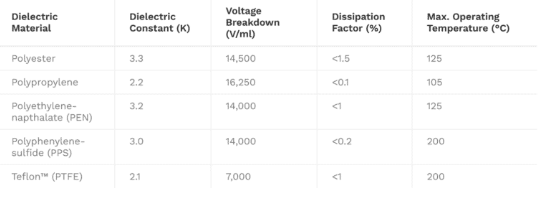

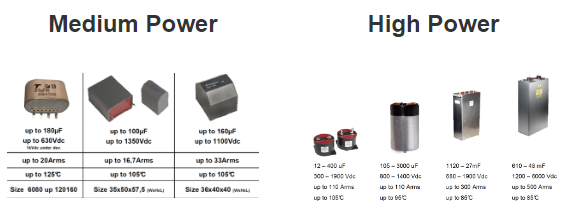

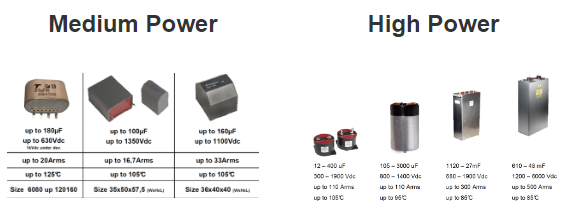

There are various forms of film capacitors on the market, from SMD chip style up to high power high voltage types:

SMD Stacked Chip

0.01uF – 15uF

30 – 400V

up to 125°C

SMD Stacked Chip

0.01uF – 15uF

30 – 400V

up to 125°C

Some typical examples of film capacitor applications:

- DC link in automotive or renewable energy generators

- AC motor and light start

- Medical defibrilators

- Railway systems

- Defence and space hardware

- Energy distribution and power correction

- X and Y safety capacitors

- EMI noise suppression

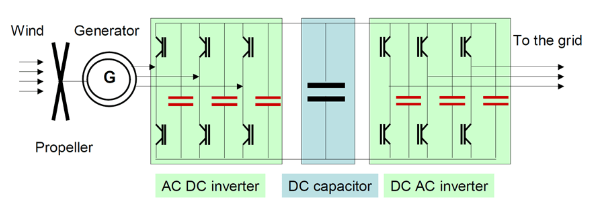

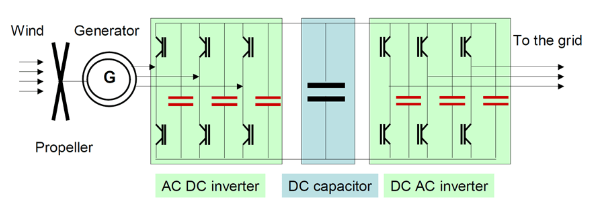

DC Link application – example of wind power generator

Some typical examples of film capacitor applications:

- DC link in automotive or renewable energy generators

- AC motor and light start

- Medical defibrilators

- Railway systems

- Defence and space hardware

- Energy distribution and power correction

- X and Y safety capacitors

- EMI noise suppression

DC Link application – example of wind power generator

Key attributes of film capacitors:

- High C*V (small size and high performance)

- High operating temperature

- High dv/dt

- High current handling capability

- Low ESR and ESL

- Parametric stability

- Environmental rugged

- Multiple encasement selections

- Broad-based applications

- Suppression, high current filters, input and output filters power, RFI, tip & ring, modems & ignition.

- Proven reliability

- Inherent self-healing and durable construction

Polar Plastics Vs Non-polar Plastic Dielectrics

Dielectric properties of a polymer largely depend upon their structure. The structure determines whether a polymer is polar or non-polar and this in turn decided the electrical properties of the polymer.

- In polar polymers (PMMA, PVC, Nylon, PC etc.), dipoles are created due to imbalance in the distribution of electrons. These dipoles tend to align in the presence of electric field. Hence, this creates dipole polarization of the material making these materials only moderately good as insulators.

- While non-polar polymers (PTFE, PP, PE, PS) have symmetrical molecules and are truly covalent. There are no polar dipoles present in them and hence in presence of electric field does not align the dipoles. However, slight electron polarization occurs due to the movement of electrons in the direction of electric field, which is effectively instantaneous. These polymers have high resistivities and low dielectric constant.

Polar plastics have a tendency to absorb moisture from the atmosphere. Presence of moisture raises the dielectric constant and lowers the resistivity. With rise in temperature, there is faster movement of polymer chains and fast alignment of dipoles. This invariably raises the dielectric constant values for polar plastics.

Non-polar plastics are not affected by moisture and rise in temperature. Dielectric constant of various plastic materials can be found in the post linked in material folder of this lesson.

Polar plastics have a tendency to absorb moisture from the atmosphere. Presence of moisture raises the dielectric constant and lowers the resistivity. With rise in temperature, there is faster movement of polymer chains and fast alignment of dipoles. This invariably raises the dielectric constant values for polar plastics.

Non-polar plastics are not affected by moisture and rise in temperature. Dielectric constant of various plastic materials can be found in the post linked in material folder of this lesson.

PET and PP totally dominate the film capacitor dielectric market. PP is a small and simple molecule. PET is „heavier” but also provides a stronger and higher tensile strength film that con be bi-axially oriented into very thin films.

Film capacitor dielectric comparison charts

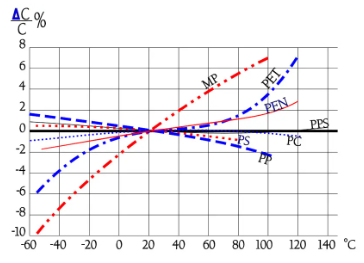

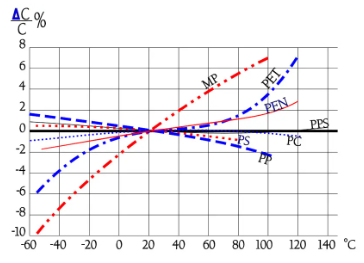

Comparison of the temperature dependence of capacitance for organic dielectrics in foil or metalized film capacitors design. Typical curves.

Comparison of Tanδ versus temperature for different organic materials film capacitors

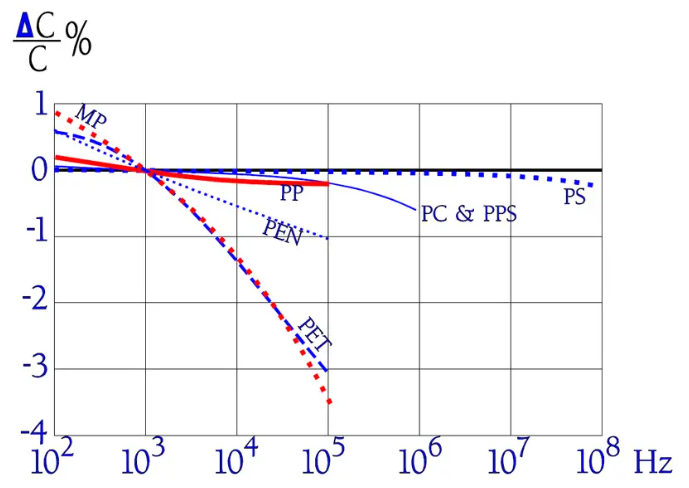

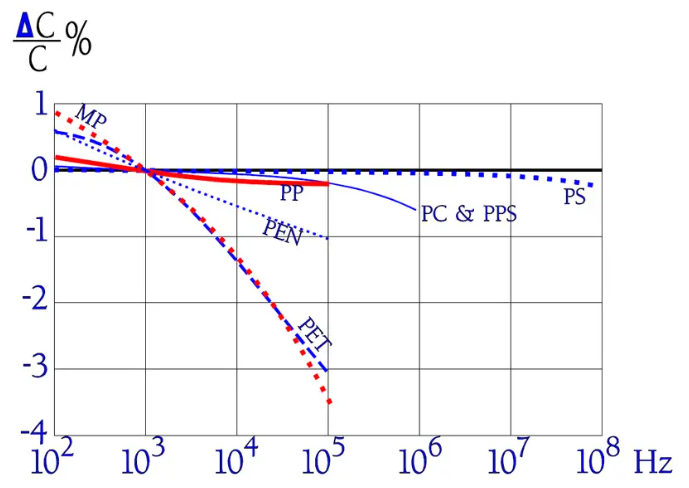

Comparison of the frequency dependence of the capacitance for organic dielectrics film capacitors. Typical curves

Comparison of the temperature dependence of capacitance for organic dielectrics in foil or metalized film capacitors design. Typical curves.

Comparison of Tanδ versus temperature for different organic materials film capacitors

Comparison of the frequency dependence of the capacitance for organic dielectrics film capacitors. Typical curves

Film Capacitor construction and manufacturing

Film capacitors can be produced as a wound or stacked foil capacitors types depending on the final application requirements and features – see figures below. The minimum rated voltage of film capacitors is mostly limited by its mechanical strength to withstand the winding process, and it typically starts from >3um per layer, corresponding to ~30V, thus, it is not in direct competition to low voltage SMD other capacitor technologies.

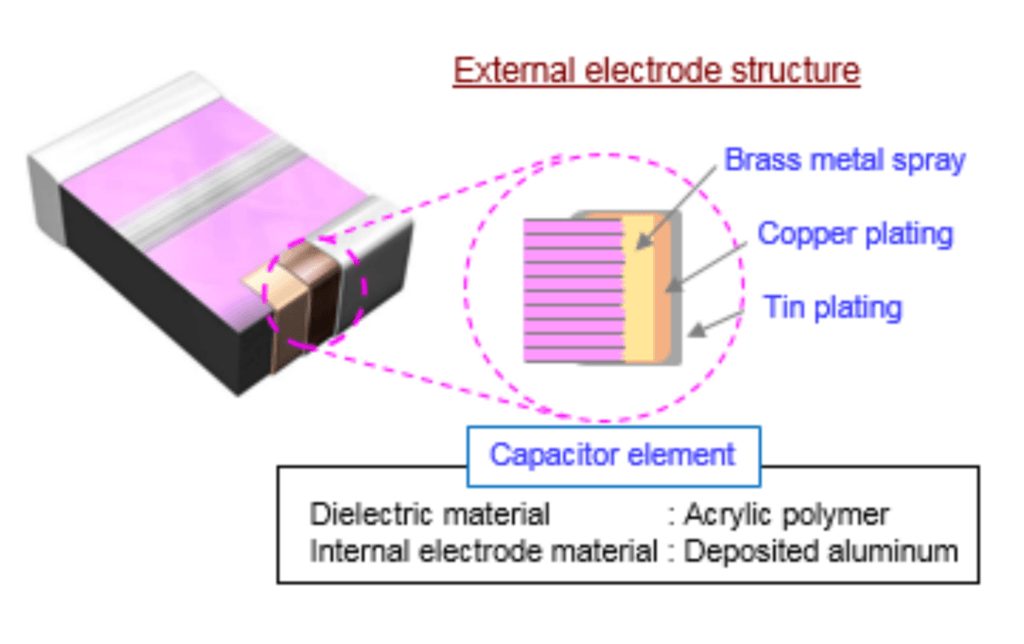

The exception is multilayer SMD stacked capacitor Rubycon PMLCAP(R), which employs electron beam curing resin as the dielectric material and vacuum deposition polymerization technology as a manufacturing method that enables dielectric thickness to be less than 1um, allowing minimum voltage (and high capacitance) from 10/16V and offer an alternative to MLCC class I capacitors even at low voltage applications.

Construction

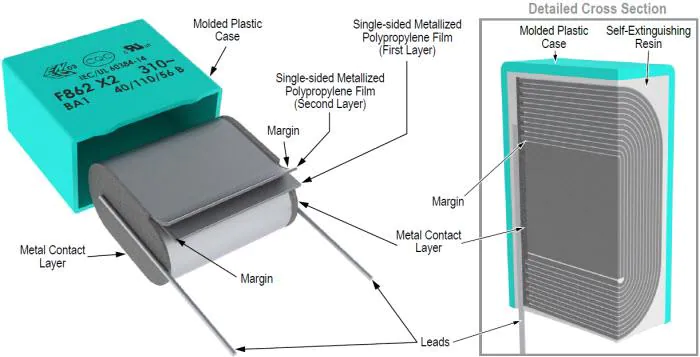

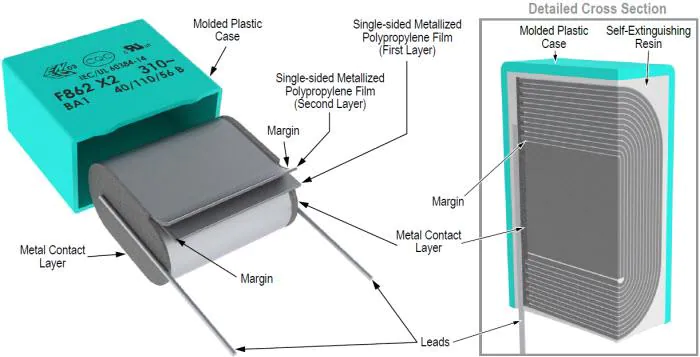

Moulded wound MKP film capacitors construction; source: Kemet

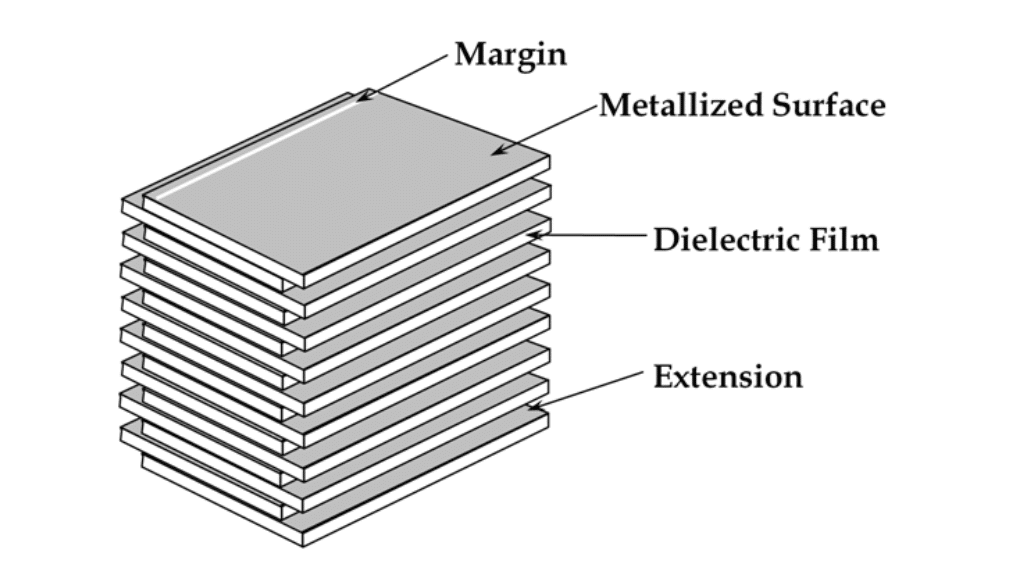

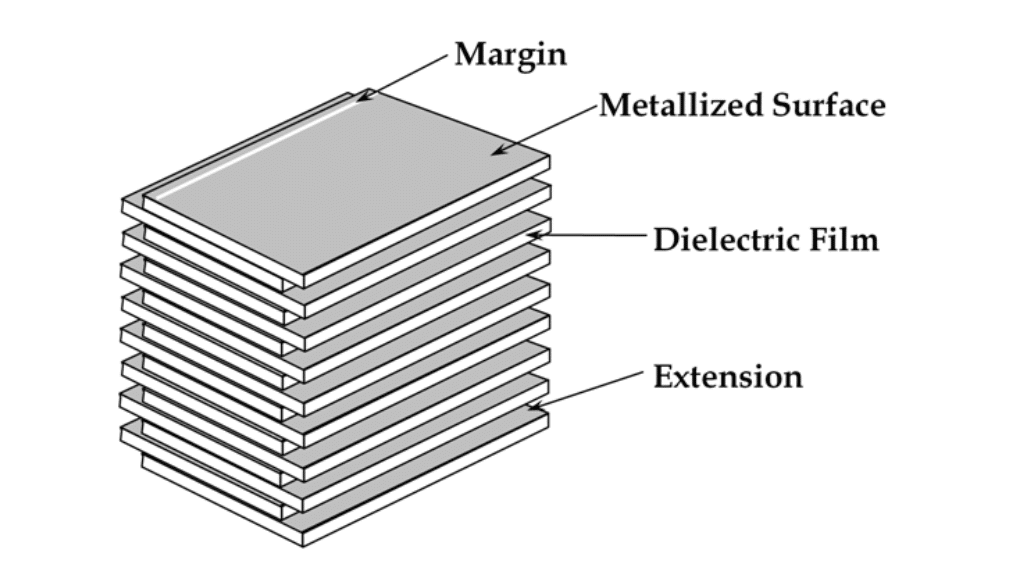

Film capacitors stacked (SMD) design

Moulded wound MKP film capacitors construction; source: Kemet

Film capacitors stacked (SMD) design

Multilayer SMD film capacitors

Manufacturing Process

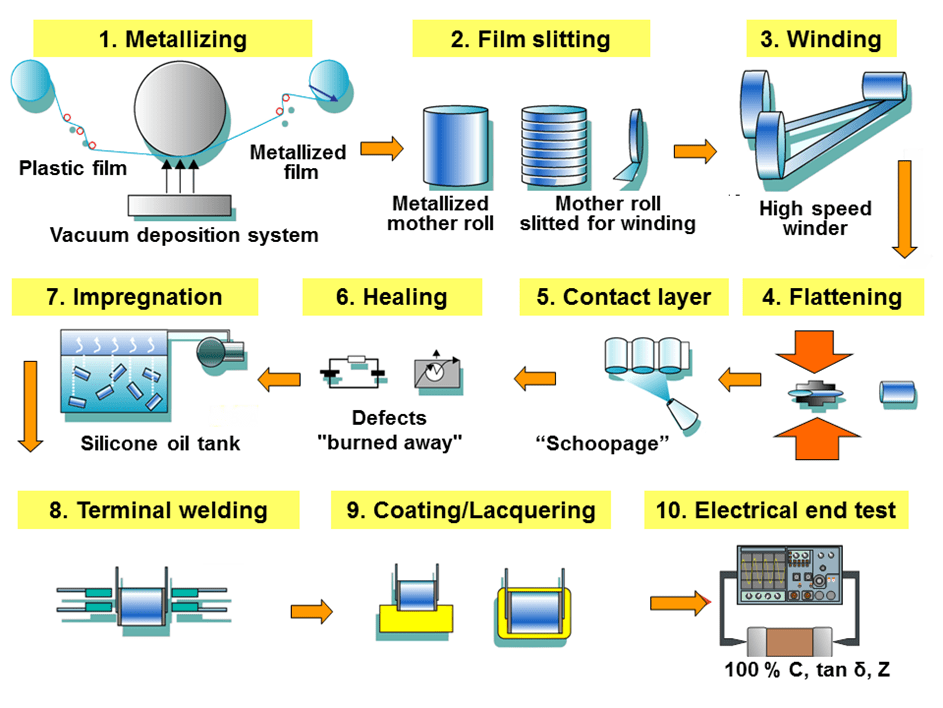

The following example describes a typical manufacturing process flow for wound metallized plastic film capacitors.

Metallized wound film capacitors manufacturing process; source: Wikipedia

- Film stretching and metallization — To increase the capacitance value of the capacitor, the plastic film is drawn using a special extrusion process of bi-axial stretching in longitudinal and transverse directions, as thin as is technically possible and as allowed by the desired breakdown voltage. The thickness of these films can be as little as 0.6 μm. In a suitable evaporation system and under high vacuum conditions (about 1015 to 1019 molecules of air per cubic meter) the plastic film is metalized with aluminum or zinc. It is then wound onto a so-called “mother roll” with a width of about 1 meter.

- Film slitting — Next, the mother rolls are slit into small strips of plastic film in the required width according to the size of the manufactured capacitors.

- Winding — Two films are rolled together into a cylindrical winding. The two metalized films that make up a capacitor are wound slightly offset so that by the arrangement of the electrodes, one edge of the metallization on each end of the winding extends out laterally.

- Flattening — The winding is usually flattened into an oval shape by applying mechanical pressure. Because the cost of a printed circuit board is calculated per square millimeter, a smaller capacitor footprint reduces the overall cost of the circuit.

- Application of metallic contact layer (“school age”) — The projecting end electrodes are covered with a liquefied contact metal such as (tin, zinc, or aluminum), which is sprayed with compressed air on both lateral ends of the winding. This metalizing process is named school page after Swiss engineer Max Schoop invented a combustion spray application for tin and lead.

- Healing — The windings now electrically connected by the school page must be “healed”. This is done by applying a precisely calibrated voltage across the electrodes of the winding so that any existing defects will be “burned away” (see also “self-healing” below).

- Impregnation — For increased protection of the capacitor against environmental influences, especially moisture, the winding is impregnated with an insulating fluid, such as silicone oil.

- Attachment of terminals — The capacitor terminals are soldered or welded on the end metal contact layers of the school page.

- Coating — After attaching the terminals, the capacitor body is potted into an external casing or is dipped into a protective coating. For the lowest production costs, some film capacitors can be used “naked” without a further coating of the winding.

- Electrical final test — All capacitors (100%) should be tested for the most important electrical parameters, capacitance (C), dissipation factor (tan δ), and impedance (Z).

Resource: Passive Components Blog

Related Articles

Subscribe now for our free newsletter

Share this post

< Back