This article is the fourth part of a complete installment on the construction, application, and features of film and foils organic dielectric capacitors, divided into 6 sections:

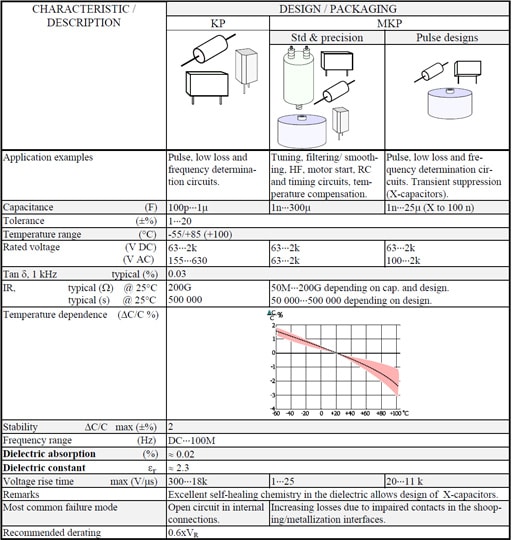

The common European abbreviations for polypropylene capacitors are PP or KP for film/foil and MKP for a metalized film.

Polypropylene (PP) is, from a molecular point of view, a non-polar dielectric with small losses and a relatively straight and moderate TC. Since the smallest film thickness is approx. 3.5 μm (0.14 mils) and εr ≈ 2.3, the capacitor can not come down to those sizes characterizing PET at low-rated voltages. But remaining good characteristics in many applications have brought up PP as a replacement for polycarbonate (PC) and polystyrene (PS), not least as a precision capacitor. PP exists in foil and metalized design and is adopted for AC, pulse, and transient suppression (X-capacitor) applications. The pulse and X-capacitor designs, however, require specific metalizing technology.

The MKP design had, from the beginning, problems with the adhesion between the metalized layer and the plastic film. This problem characterizes non-polar dielectrics consisting of molecules and has caused many problems, such as gluing components to circuit boards. The plastic surface film has to be raised and roughened, which among other things, can be done by etching, flame exposure, electron irradiation, or corona. Today the MKP design is well established, and the adhesion problems have passed.

Figure 17. Example of an MKT capacitor design intended for interference suppression.

The demand for filtering/interference suppression of thyristor-generated noise voltages has brought forth the same type of large capacitors as shown for PET, but here, the low ESR losses allow quite different r.m.s. currents, for example, at high frequencies.

The recommended absolute maximum temperature is +105°C. We recommend a max of +85°C with the remark that developments of new films are going on to offer a temperature range above +105°C as a maximum operating temperature. Current temperature limitations still make PP difficult for chip designs.

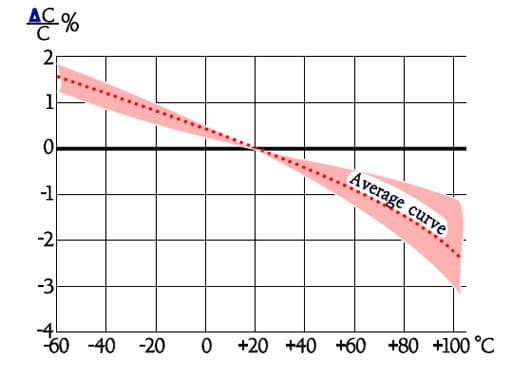

Temperature and frequency dependencies

Figure 28. Typical curve range for capacitance versus temperature of the PP capacitors KP and MKP design.

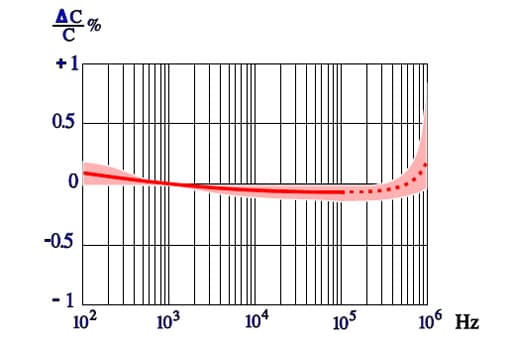

Figure 29. Typical diagram of capacitance versus frequency for PP capacitors KP

The frequency dependence of capacitance for PP capacitors is moderate. In Figure 29. the broken part of the curve indicates an increase in capacitance. This increase is not physical but depends on the influence of series capacitance measurements.

Figure 30. Typical curve range of Tanδ versus temperature for PP capacitors MKP and KP.

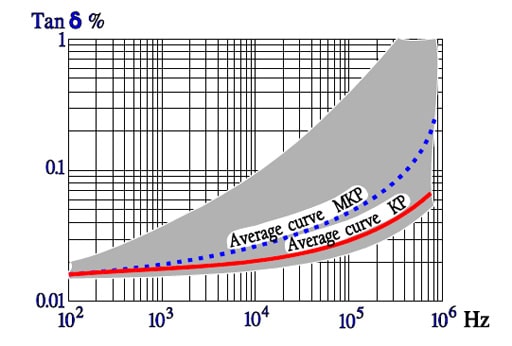

Figure 31. Typical curve range of Tanδ versus frequency for PP capacitors KP and MKP.

Note in Figure 30. the outstanding low loss factor for PP over the whole temperature range. The curve area in Figure 31. represents capacitance up to hundreds of nF: the higher the capacitance, the more significant losses.

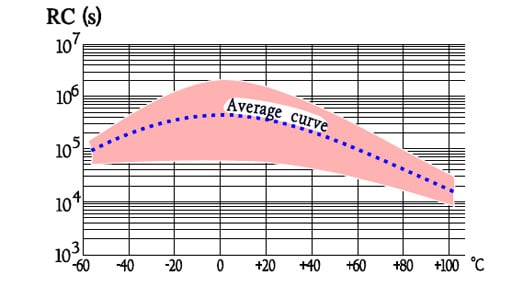

Figure 32. Typical curve range showing the IR versus temperature for PP capacitors KP and MKP.

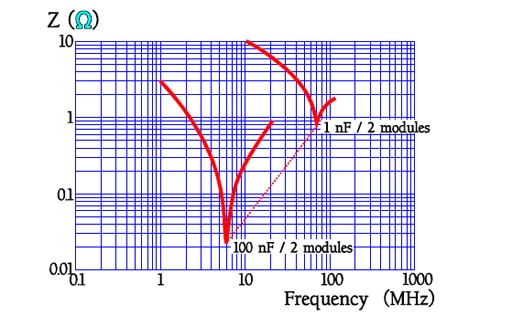

Figure 33. Examples of resonance frequencies for 2 modules lead space PP capacitors MKP.

Designs with foil or hermetic seals have higher IR than corresponding metalized and plastic encapsulated types.

Failure modes

Any characteristic failure mode just for PP capacitors is not distinguishable. Here what was said about PET usually applies.

Table 4. POLYPROPYLEN (PP) / KP / MKP

Resource: Passive Components Blog