Switched-mode power supplies are becoming ever more widespread. The semiconductor manufacturers have contributed by offering a wide range of integrated circuits with simplified circuit design. Care must be taken in selecting the appropriate power inductor storage choke to fully utilize the advantages of switching regulators.

This article is split into two chapters:

- Calculation of power inductors

- Example of high current inductor types

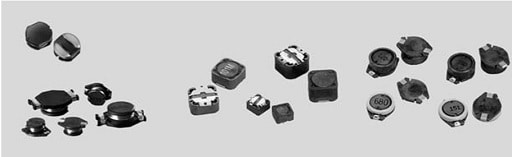

High Current Inductor Types

SMD NiZn Ferrite Core Storage Choke

SMD storage chokes with highly dynamic and low loss NiZn ferrite cores are suitable as chokes in switching control applications up to a clock frequency of approx. 10MHz and offer high current loading capacity and low DC resistances.

There are a multitude of construction types available for the different types of applications:

- Magnetically shielded series

- Unshielded versions series

Figure 4. SMD NiZn ferrite core storage power chokes WE-PD

Data book specifications

Inductance L: Different measurement conditions apply for the different construction series. The inductance is stated at a certain test frequency and measurement voltage (see datasheet).

Current rating IN: The current rating of the inductor is specified as the DC current at which the inductor exceeds the permitted tolerance limits (DL) or the self-generated heating (DT) exceeds a certain limit. The smaller of the currents defined by the two conditions is termed the current rating of the inductor. This is how ever not the saturation current, which is higher than the current rating.

DC resistance DCR: The windings resistance value is measured with an ohmmeter at an ambient temperature of +20 °C. The test current for resistance measurement is a small DC current, which does not lead to a significant temperature increase in the wire. As values in the milliohm range are measured here, a 4-wire measurement must be made to minimize measurement errors.

Operating temperature: The ambient temperature when operating the SMD NiZn series of storage chokes at full current rating load should generally range from –40 °C to +85 °C. The self-heating of the component must be taken into account at higher ambient temperatures in order that the permissible solder joint temperature is not exceeded or the wire insulation damaged. The wire used can withstand a temperature of up to +150 °C. The ferrite core itself may be used over a far greater temperature range (approx. –50 °C to +250 °C [Curie temperature]). However, in this case, the tolerance limits of the inductor may be exceeded due to the temperature dependence of permeability.

Operating temperature = ambient temperature + self-heating < +125 ºC

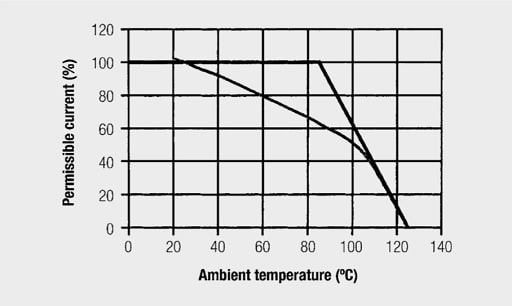

The above curve on Figure 5. assumes that self-heating is permissible up to a maximum temperature sum (component + ambient temperature) of +125 °C. The current must be reduced above an ambient temperature of +85 °C. The curve below is intended for critical applications, in which the coil itself should only generate a small amount of self-healing.

Insulation resistance: The insulation resistance between windings and coil core is more than 100 MΩ for a test voltage of 500 VDC<sub>DC</sub>.

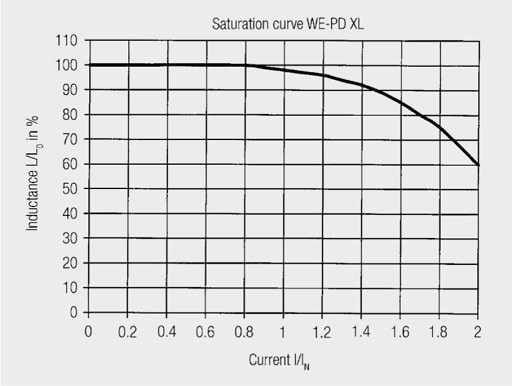

Saturation current Isat: The saturation current is the DC current at which a certain percentage reduces the zero current inductance.

The percentage of inductance decrease is however not standardised and can be defined differently for each package type. In datasheets – and especially when comparing data from different manufacturers – very close attention must be paid to the definition point. A printout of the measurement curve “Inductance versus DC premagnetization” is better still. Here the user can, for example, check in detail how the inductor behaves in the case of overload or at the moment it switches on. An example for a standardised curve is shown in Figure 6.

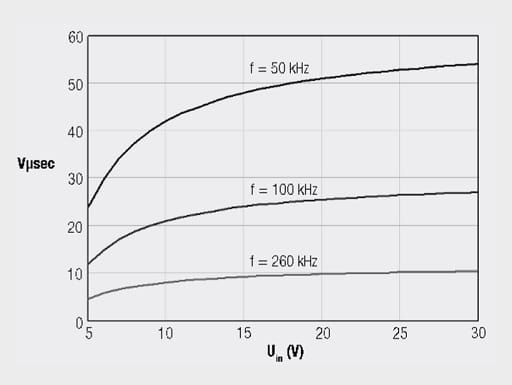

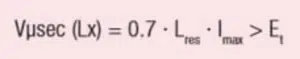

Volt-µsec product: As a result of their effective magnetic area Aeff, storage chokes can only be driven to a maximum value – the so-called Volt-µsec product. The following calculation rule applies for the step-down controller to determine the necessary Vµsec product of storage chokes:

![inductor Volt-µsec calculation eq. [9]](https://www.doeeet.com/content/wp-content/uploads/2025/01/inductor-Volt-µsec-calculation-eq.-9.webp)

inductor Volt-µsec calculation eq. [9]

- Et = V-µsec

- Uin(max) the maximum input voltage in Volts

- Uout the output voltage of the controller

- f the switching frequency in Hz.

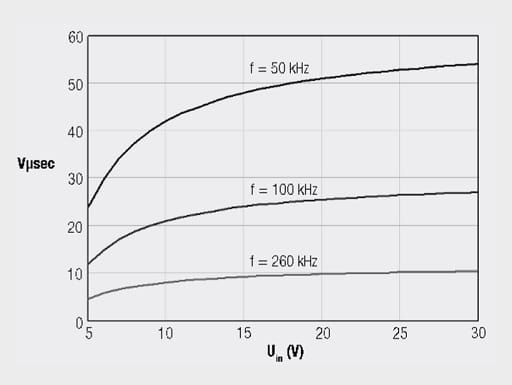

With increasing switching frequency, the necessary Vµsec product of the storage choke becomes lower; however, with increasing input voltage, it becomes higher. This relationship is again illustrated in Figure 7.

Figure 5. Derating curve of NiZn SMD storage choke (source: WE-PD datasheet)

Figure 6. The standardised curve of NiZn SMD storage choke (source: WE-PD datasheet)

Figure 7. Vµsec with variable input voltage and different switching frequencies for the step-down controller

Practical tips:

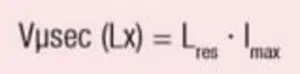

For some types in the SMD NiZn SMD chokes manufacturers also provide Vµsec specification in their datasheets. If this information is missing, it can be read off from the measurement curve “Inductance versus DC current premagnetization”. Here you locate the inductance plateau where you read off the associated current and residual inductance values and calculate the Vµsec product as follows:

- Lres in µH

- Imax in A.

Ferrite storage chokes

For ferrites, the saturation curve shows a very steep decline beyond a certain DC current value (“hard saturation”). For this reason it is recommended to reduce the Vµsec product calculated in this way and therefore to then optimise inductor selection.

Iron powder core storage chokes, Superflux, WE-PERM etc. have a constant decrease in inductance due to the DC-premagnetization (soft saturation). As a rule:

NiZn storage choke core material parameters

The NiZn (WE-PD) core material parameters are described by the following power loss formula:

The corresponding curve is shown in Figure 8

Figure 7. Vµsec with variable input voltage and different switching frequencies for the step-down controller

Power Loss and Temperature Increase in the Component

Now the power loss can be approximately determined; the question arises of the temperature rise of the component in operation. Measurement curves can be generated for the rise in temperature of the components with DC currents. Here are the questions to be resolved:

How was the component measured?

- mounted on a PCB with a lot of copper (= cooling element!) OR

- only the component via a thin and poor heat-conducting connection

After what time was the temperature read off from the component (thermal time constant !)

The following approximation formulas can be useful in the design phase; however, they do not obviate measurement under real operating conditions. Determination of total power loss in the storage choke:

a) Copper losses:

![inductor copper losses eq. [10]](https://www.doeeet.com/content/wp-content/uploads/2025/01/inductor-copper-losses-eq.-10.webp)

inductor copper losses eq. [10]

b) Core material losses from empirical formulas

This results in the total power loss (without further losses such as the skin effect etc. …):

![inductor core material power loss eq. [11]](https://www.doeeet.com/content/wp-content/uploads/2025/01/inductor-core-material-power-loss-eq.-11.webp)

inductor core material power loss eq. [11]

Temperature increase in the component (large surface)

![inductor temperature increase eq. [12]](https://www.doeeet.com/content/wp-content/uploads/2025/01/inductor-temperature-increase-eq.-12.webp)

inductor temperature increase eq. [12]

- Ptot in (W)

- surface area A in (mm2)

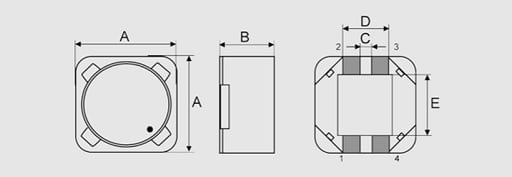

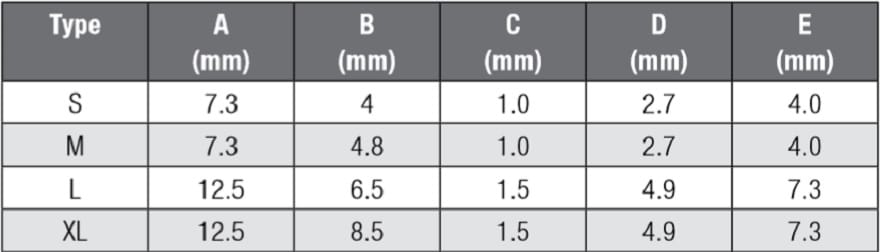

NiZn Power Ferrite Core Double Chokes

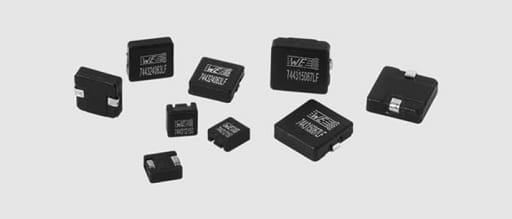

NiZn power ferrite core double chokes (Figure 9.) with two separate windings expand the standard spectrum of storage chokes with more features.

Features:

Two separate windings on a common ferrite core

- Available in a 1: 1 winding (standard), but also in other winding ratios (customer-specific)

- Bifilar winding for minimal stray inductance / high coupling factor • (k ~ 0.985 … 0.990) or separate layer winding with increased leakage inductance

- Operating voltage up to 80VDC

- Isolation voltage 100VDC max

Applications:

- SEPIC switching controllers (functional principle – see Chapter III/7.4)

- CUK switching controller (switching controller with negative output voltage)

- Switching controllers with a second, unregulated output voltage (auxiliary voltage)

Operating temperature:

The ambient temperature of a double choke under a fully rated current load is usually between –40 °C and +85 °C. The self-heating of the component must be taken into account at higher ambient temperatures in order that the permissible solder joint temperature is not exceeded or the wire insulation damaged.

The wire used can withstand a temperature of up to +150 °C. The ferrite core itself may be used over a far greater temperature range (approx. –50 °C to +250 °C [Curie temperature]). However, in this case, the inductance tolerance limits may be exceeded due to the temperature dependence of permeability.

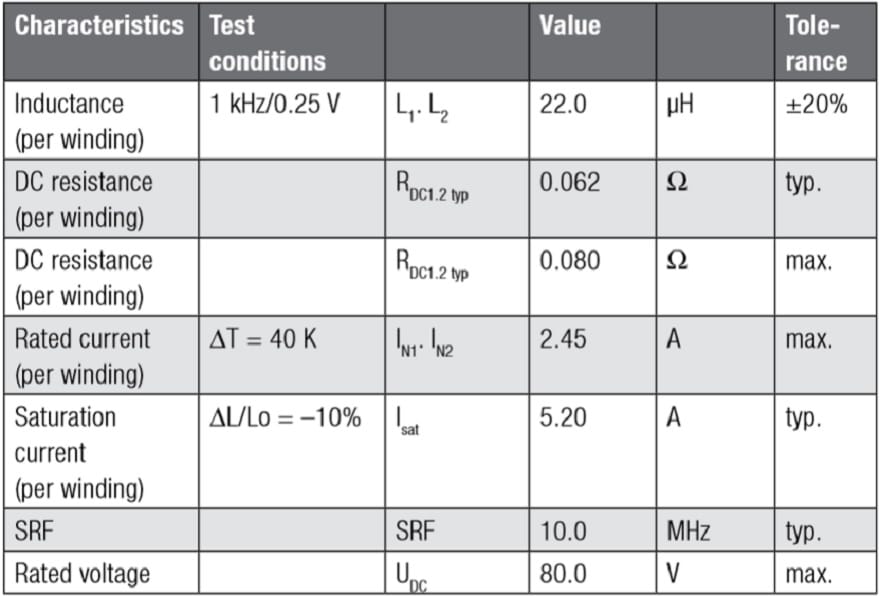

Electrical characteristics

Rated current: The self-heating for the pair of windings passing maximum current should not sum to more than +40°C. This is a conservative number, datasheet specification may differ per type and manufacturer.

The rated current is determined for each winding, which passes current on its own, leading to a temperature increase of up to +20 °C and is specified as IN1 and IN2, respectively. If both windings pass their rated current at the same time, this leads to self-heating totaling +40 °C.

DC resistance: Correspondingly, the specification for the winding resistance of the two individual windings is found from individual measurements. Attention: Please compare the datasheet specifications carefully – often the parallel configuration of the two windings is found in the literature as rated current / DC resistance, which suggests a higher rated current and lower DC resistance. In practice this is of course, not the application for this series of chokes!

Saturation current: In the case of the double choke with the same inductance, it is sufficient if just one of the windings carries the saturation current. The second winding is inevitably reduced in its inductance. The value is identical for the same inductance; the saturation current per winding is specified for dissimilar inductance values.

Figure 9. Picture and characteristic data of some shielded double chokes (source: WE)

Table 4. Electrical characteristics of the shielded power double chokes WE-DD

TPC “Tiny Power Choke“ SMD storage chokes

TPC “Tiny Power Choke“ of storage chokes (Figure 10.) is usually for applications for which the packing density and the package height is important. This design enables the production of the smallest wire-wound inductors in dimensions such as 2.8 x 2.8 x 1.0 mm.

Figure 10. TPC “Tiny Power Choke“ SMD Storage Chokes

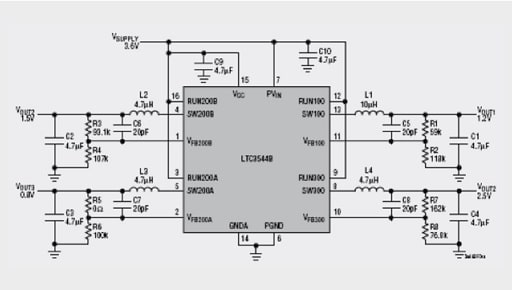

These chokes are mostly used for switching controllers that have several outputs integrated in one IC, e.g. LTC3544B. (Figure 11.) This IC has 4 outputs at which different voltages, output currents and switching frequencies are adjustable.

The core material used is typically NiZn and is therefore suitable for switching frequencies up to 10 MHz. The saturation current is defined as a –35% inductance drop in relation to the zero current inductance, which is usually typical for inductance in this small package. Magnetically shielded versions, as in Figure 10. are suitable for switching controllers, for example, in mobile applications.

SMD High-Current Inductors

Laptop computers and motherboards of modern computers are equipped with processors, whose clock frequencies may be 1 GHz or more. Processor manufacturers rely on low supply voltages in order to maintain losses in integrated circuits within tolerable limits and to attain the required switching speeds. These lie between 1 and 3.3 Volts, depending on the processor generation.

Components require large currents at the same time. Current inputs of up to 60A per processor are not a rarity and cannot be handled by well known switching regulators. The so-called multiphase switching converters fulfill the intelligent power management concept required. Because of the high switching frequency and the output current requirements, one needs only small inductance with high current capability and low losses. SMD high-current inductors are suitable for these applications.

Figure 12. SMD High current inductor (WE-HC series)

The core material used for high current inductors may require high-purity alloy of various types of iron powders, which shows significantly lower core losses than conventional iron powder cores.

Thermal aging: Thermal aging can lead to the destruction of the organic binder used, especially at high operating temperatures with standard iron powder material. A thermal avalanche effect can consequently occur, which may finally destroy the core material. For standard iron powder materials and those not thermally treated for reasons of their production process, the rule of thumb applies that the maximum temperature of +125 °C measured at the component should not be exceeded for a prolonged period. Nevertheless, modern materials with practically no thermal aging are now also available by leading manufacturers.

The core material of high current inductors can withstand high temperatures up to +200°C or even higher.

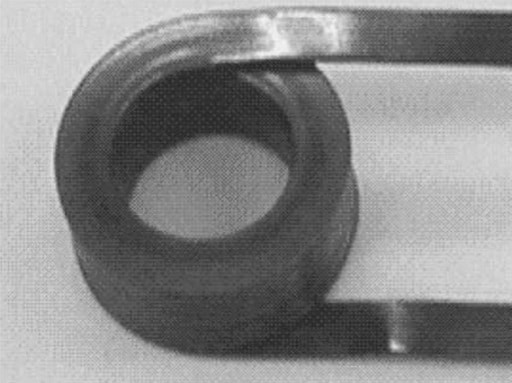

Flat wire types. High current inductors can use a rectangular flat wire, which proves to be a major advantage over conventional round wire designs in terms of AC resistance loss. A flat wire (Figure 13.) inside the choke is used in place of the conventional round wire.

Figure 13. High current inductor flat wire winding

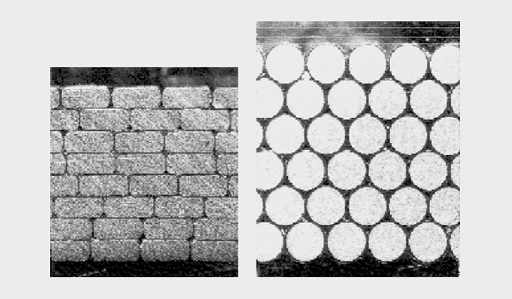

Figure 14. Comparison of packing density for equal inductance between flat wire and round wire windings

Flat wire windings offer the following advantages:

Large wire surface – thus low high-frequency losses (skin effect)

- Low winding capacity – hence high self-resonant frequency

- Low DC resistance – thus low self-heating at high prolonged currents

- High packing density and, therefore smaller component size than comparable chokes with round wire (Figure 2.57)

- High operating temperature up to max. +150 °C

Through the combination of low-loss core material and flat wire windings inside the core, achievable performance of SMD high-current inductors can be:

- Small SMD component size such as 6.6 x 7.3 mm2, 10.5 x 10.0 mm2 or 13.5 x 12.8 mm2 with a height of 3.4 mm to max. 4.9 mm.

- Open-circuit inductance L0, tested at 100 MHz with 0.25 VAC

- Inductance rating LN at current rating IN and self-heating < +50 °C

- Min. inductance at max. current Imax and self-heating < +100 °C

- Min. DC windings resistance DCRmax at Ta = +25 °C

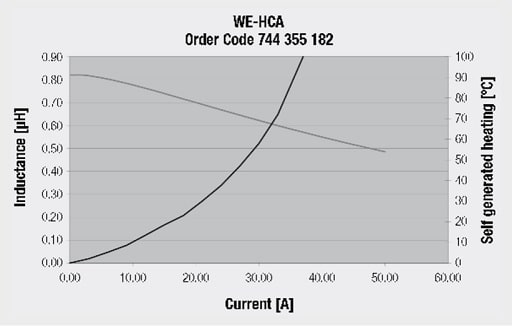

Figure 15. shows the typical behavior of SMD high-current inductor 0.82 µH choke 13.2 x 12.8 x 6.2 mm.

The component has an inductance of 0.65 µH at the specified rated current of 27 A and demonstrates typical self-heating of +50 °C. The inductance is very stable under current load; the limiting factor is the self-heating of the component. Even at a current load of 50 A the inductance does not drop more than 30% from the open-circuit inductance. The self-heating is well over +100 °C, however.

Flat wire, low core loss inductors represents a highly dynamic and robust types of storage chokes, especially suited for use in high-current switching converters and multiphase or polyphase converters. Additional application areas are in high-current interference suppression chokes and as a replacement for rod core chokes.

Figure 15. Inductance curve and self-heating against current on flat wire low loss core SMD inductor example

Radio Interference Suppression Choke

Radio interference suppression chokes use usually iron powder toroidal cores with a very low stray field. High current loading capacity is achieved through high saturation magnetization. The useable maximum upper-frequency range of this component extends from a few MHz to approx. 30 MHz, depending on the type.

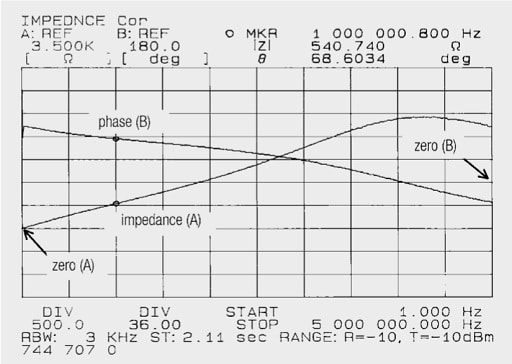

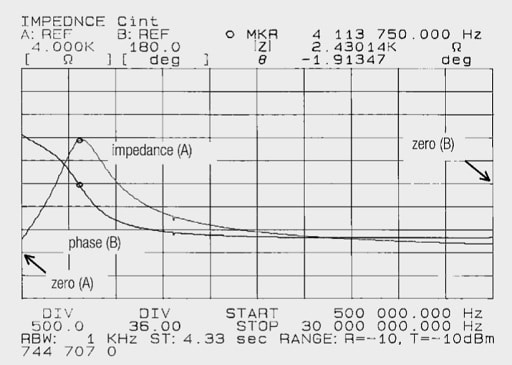

The impedance-phase curve against the frequency of a typical toroidal core choke is shown in Figure 16. and 17.

Figure 16. Impedance and phase of the toroidal core choke (100 µH) against frequency (0 MHz–5 MHz)

Figure 17. Impedance and phase of the toroidal core choke (100 µH) against frequency (0.5 MHz-30 MHz)

It may be seen from Figure 17. that the resonant frequency is at 4.1 MHz. Above 4.1 MHz the capacitive character of the choke predominates, at 30 MHz the impedance has fallen to approx. 200 Ω. The impedance is almost linear (Figure 16.) up to the resonant frequency of 4.1 MHz.

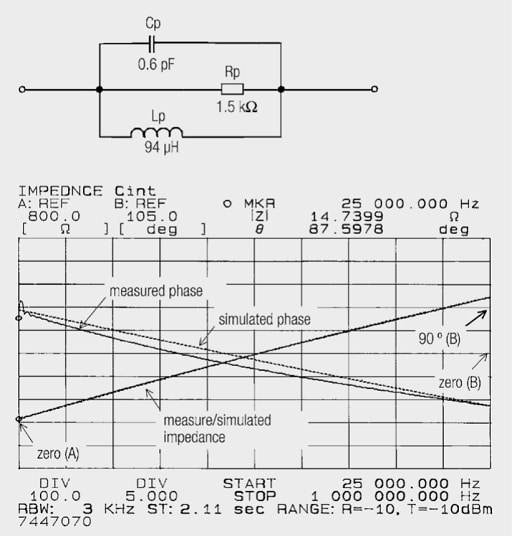

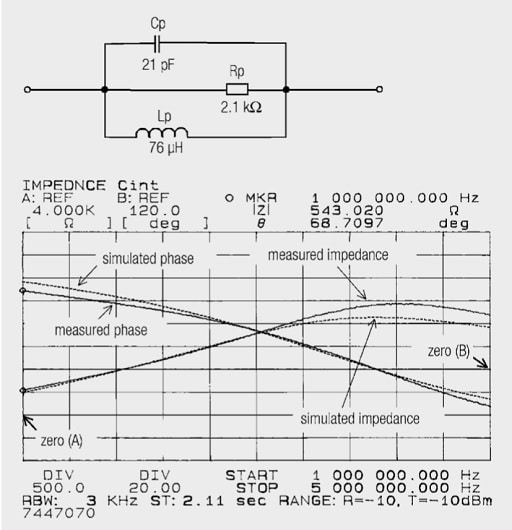

Due to the frequency dependence of complex permeability, calculations are only feasible in limited frequency bandwidths and sufficiently far (in the linear range) below the resonant frequency. Figure 18. shows the equivalent circuit of the choke in the 25 kHz to 1 MHz range, Figure 19. the equivalent circuit in the 1 MHz to 5 MHz range. The values were found using an impedance analyzer, calculating on the basis of the components’ equivalent circuit. Due to high non-linearity, the equivalent circuit can be simulated over a wide frequency range with just 3 components.

Figure 18. Equivalent circuit with associated measured and simulated impedance – phase curves

Figure 19. Equivalent circuit with associated measured and simulated impedance–phase curves

From the measurement curves impedance and phase an increase in eddy-current losses and a decrease in the complex permeability can be seen.

The impedance can be calculated as a function of frequency. The broken line in Figures 18. and 19. are the simulated curves with the values given by the equivalent circuits. It shows that without considering the complex permeability and its frequency dependence, the calculation can be performed with limited accuracy.

Practical tip:

Here another word on the saturation of the ferrite ring: The effective core cross-sectional area is inversely proportional to the saturation current and proportional to the impedance. This means that wherever possible, the larger core cross-section area should be chosen.

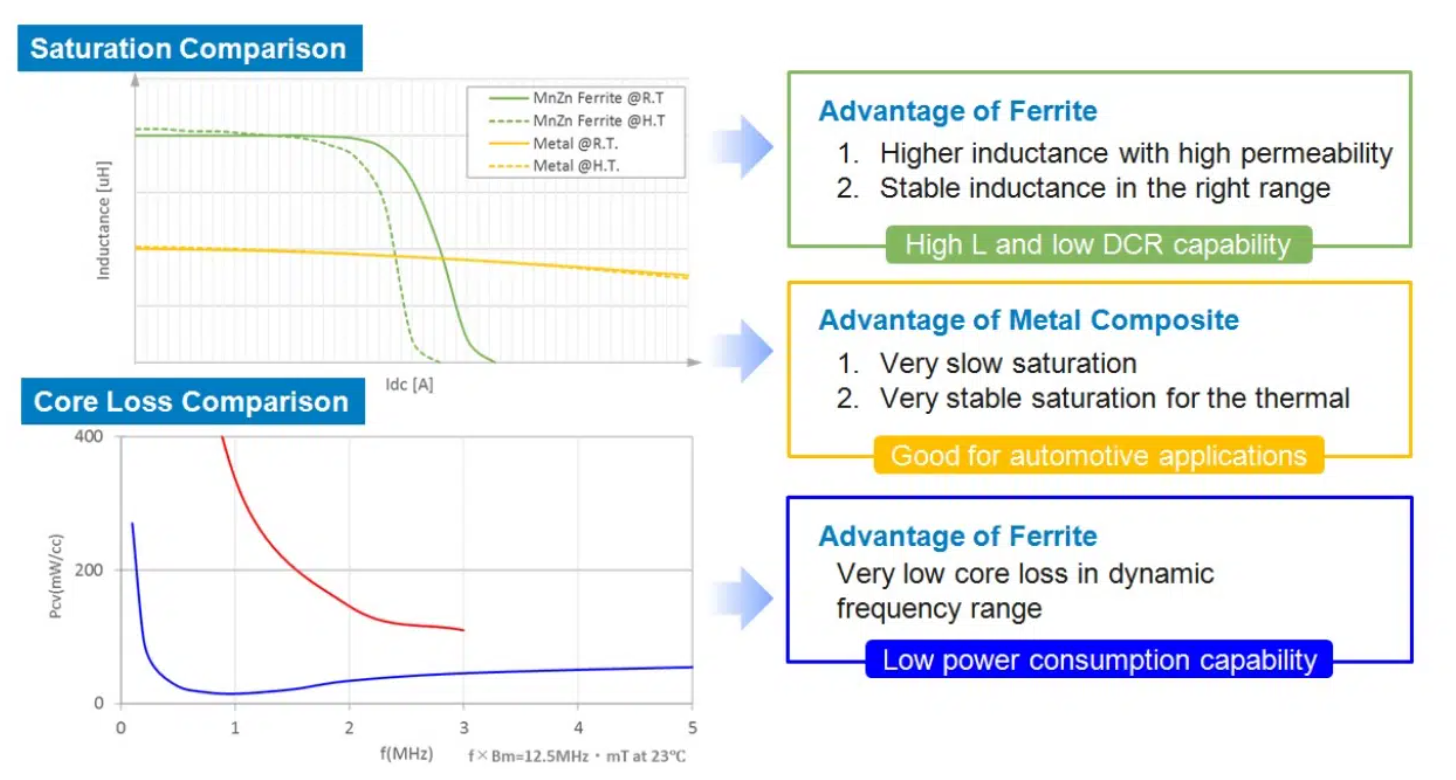

Metal Composite Inductors

Latest metal composite inductors (Figure 20.) come with a remarkably higher energy density compared to the ferrite inductors. This leads to 30% – 50% smaller case sizes which, for example, serves the trend for downsizing high current ECU power circuits. Furthermore, smaller case sizes also have the pleasant side-effect of being less prone to get damaged in harsh or vibrating environments. A true plus in terms of long term reliability.

Figure 20. metal composite inductor and its construction; source: KEMET

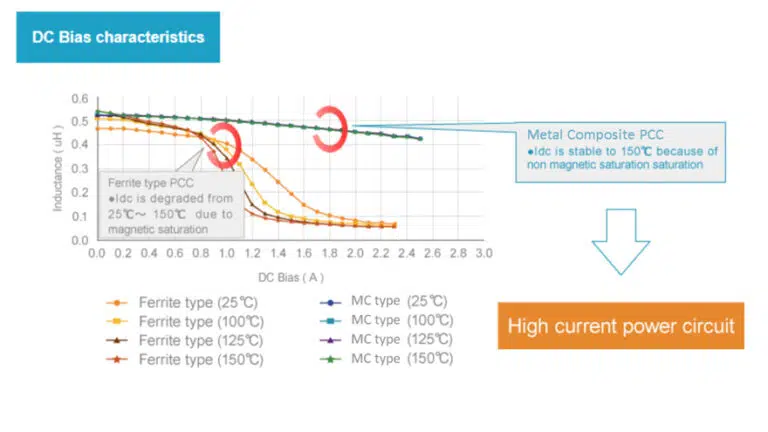

DC Bias Characteristics

Excellent magnetic saturation characteristics of metal composite inductors (i.e. Ferrite core = 0.4T vs Metal Composite Type = above 1.5T) render it difficult to magnetically saturate, resulting in good inductance vs current performance without a substantial drop off. In comparison, ferrite inductors do not only suffer from a fairly quicker inductance drop-off.

Their inductance also suffers the undesirable effect that it varies with temperature, whereas the performance of their metal composite counterparts is stable over the entire specified temperature range. Naturally, the qualification of applications using ferrite inductors needs increased effort compared to metal composite inductors due to consideration of different temperature ranges.

Low loss characteristics of metal composite vs ferrite inductors assist the realization of high-efficiency power circuits such as ECU and simplify thermal design considerations.

High Mechanical Shock and Vibration Robustness

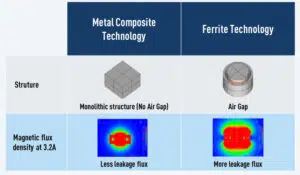

Ferrite inductors consist of several sintered parts being constructively composed with an air gap inside the body, whereas metal composite inductors are based on a monolithic design without air gap.

Due to that assembled structure, the ferrite types’ resistance to vibrations is limited to <4G to a maximum of 10G. Opposed to that, the monolithic structure of the metal composite inductors leads to a significantly higher vibration resistance – up to 50G, depending on the inductor type. This may be advantageous for harsh environments and high vibration applications such as automotive, industrial or aerospace/defense electronics.

Low EMI Noise

Also in terms of a lower leakage flux outside the power inductors, the point goes to the metal composite types: Their monolithic structure causes by far less leakage as the magnetic flux simply is concentrated inside the inductor housing. See Figure 23.

Figure 23. EMI noise / magnetic flux comparison of ferrite vs metal composite inductors; Source: Panasonic

Resource: Passive Components Blog