The object of this post is to define which EEE components and technologies are radiation sensitive. There must be taken into consideration the high relevance in space projects that parts election has. Some radiation effects can be mission limiting where they lead to a prompt or accumulated degradation which results in subsystem or system failure, or catastrophic system anomalies. Other effects can be a source of interference, degrading the efficiency of the mission.

There must be considered radiation effects on the matter is a huge field of knowledge. The main goal of this post is to clearly summarize in a schematic way which EEE parts/technologies are sensitive to each different radiation effect.

For a better understanding, the information is split into 3 points that represent the different radiation mechanisms which affect an electronic component, giving a brief introduction of each as well as presenting a summary table of technologies and effects.

Total Ionizing Dose Effects

It is a cumulative long-term ionizing damage. Ionization induced in semiconductor materials or associated insulators, such as silicon dioxide layers, can lead to charge trapping or the formation of interface states at the semiconductor‐insulator boundary, affecting component behaviour or material properties. In MOS devices, the trapped charge can lead to a shift in the gate threshold voltage, and for semiconductors in general, interface states can significantly increase device leakage currents. Materials such as polymers and glasses are also susceptible to total ionizing dose (TID) effects and can suffer degradation in mechanical, electrical and optical properties.

The atomic particles involved in TID effects are electrons, protons and bremsstrahlung.

Table 1 identifies the technologies used in space applications whose TID effects shall be analyzed.

| Technology Category | Sub-category | Effects |

|---|---|---|

| MOS | NMOS PMOS CMOS CMOS/SOS/SOI |

Threshold voltage shift A decrease in drive current A decrease in switching speed Increased leakage current |

| BJT | — | hFE degradation, particularly for low-current conditions |

| JFET | — | Enhanced source-drain leakage currents |

| Analogue electronics | — | Changes in offset voltage and offset current Changes in bias-current Gain degradation |

| Digital electronics | — | Enhanced transistor leakage Logic failure from: – Reduced gain (BJT) or – Threshold voltage shift and reduced switching speeds (CMOS) |

| CCDs | — | Increased dark currents Effects on MOS transistor elements (described above) Some effects on CTE |

| APS | — | Changes to MOS-based circuitry of the imager (as described above)-including changes in pixel amplifier gain |

| MEMS | — | Shift in response due to charge build-up in dielectric layers near to moving parts |

| Quartz resonant crystals | — | Frequency shifts |

| Optical material | Cover glasses Fiber optic Optical, components, coatings, instruments and scintillators |

Increased absorption Variation in absorption spectrum (colouration) |

| Optical materials | Alkali halides Silica | Reduced transmission |

| Radiation detectors | Semiconductor ϒ-ray & X-ray detectors: Si, HPGe, CdTe, CZT |

Reduced charge collection efficiency (calibration shifts, reduced resolution) Poorer timing characteristics HPGe show complex variation with temperature |

| Semiconductor charged-particle detectors | Reduced charge collection efficiency (calibration shifts, reduced resolution) |

Table 2. Technologies sensitive to Displacement Damage effects

Single Event Effects

Single event effects are a collection of phenomena whereby microelectronics can be disrupted or permanently damaged by single incident particles (as opposed to effects like total ionizing dose where cumulative damage occurs from many particles). Protons and heavier ions, and neutrons can induce such effects. In the case of heavy ions, this occurs by direct ionization of sensitive regions of the semiconductor, and for protons and neutrons, their nuclear interactions within or very near to the active semiconductor can produce localized charge generation.

SEE phenomena can be divided into two sub‐groups:

- Destructive effects, where high‐current conditions are induced which have the potential to destroy the device. SEE examples include single event latch‐up (SEL), single event gate rupture (SEGR), single event burn‐out (SEB), and single event snap‐back (SESB)

- Non‐destructive effects, in which data are corrupted or the device is placed in a different operational state or power cycling is employed to return the state of the device to its normal condition. Examples of such effects include single event upset (SEU), multiple‐bit upset (MBU), multiple‐cell upset (MCU), single‐word multiple‐bit upsets (SMU), single event functional interrupt (SEFI), single event hard error (SEHE), single event disturb (SED), and single event transient (SET).

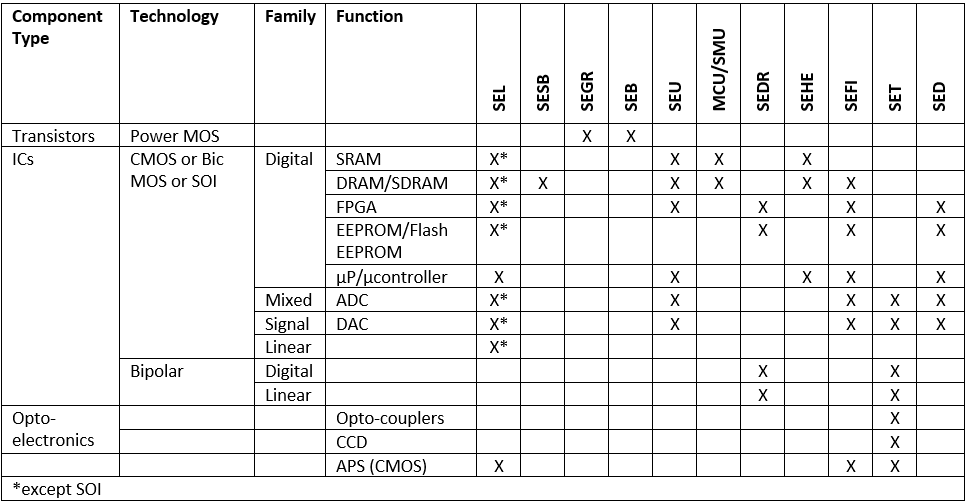

Below, Table 3 showing technologies and components susceptible to SEE effects. If one of those is intended to be used in a space mission, SEE probability and effects shall be assessed.

Table 3. Technologies sensitive to Single Event effects

Tables 1, 2 and 3 are taken from ECSS–ST-10-12C standard of the European Cooperation for Space Standardization.

Future posts will develop certain aspects such as deep analysis of each radiation mechanism, components validation testing, radiation design margins or shielding solutions for space used parts.

Juanjo Medina

Juanjo Medina has a Degree in Industrial Engineering by the University of Sevilla and has developed his professional career in I&C projects. Having joined Alter recently this 2020, he works as part of the EEE Parts Engineering Department, providing procurement support especially to german customers.